mHandheld industrial laser welding machine company to introduce you to the handheld laser welding machine knowledge, we all know that in the laser processing process can not be used, and laser welding machine has many advantages, not only small welding seam, and welding seam beautiful, precision is also high.

The laser welding machine has a lot of advantages, not only the welding seam is small, but also the welding seam is beautiful and precise. However, some people do not have a good grasp of the correct welding method when using the industrial laser welding machine for welding, which greatly reduces the efficiency of the laser welding machine, and sometimes even causes the laser welding machine to suddenly not produce light.

Laser welding machines, also known as laser welding machines, laser welding machines, laser welding equipment, etc., are a type of laser equipment machine used in the processing of materials.

A fiber laser welding machine suddenly not light?

1, if the laser welding machine used for a period of time, and the light power intensity is decaying, it may be the laser light source components aging caused.

2, if the previous laser welding machine light stable and light power intensity is stable, then it may be the following two problems caused by.

① software boards and other control systems out of order.

② optical path movement, or power supply, laser generator, cooling system and other hardware problems.

The laser welding machine suddenly not light solution

1, observe the welding machine part of the display light is normal, if the laser welding machine part can be converted over but the welding display is not light first look at the CNC part of the laser button is closed, if closed then open the laser button. If the laser button is normal, open the CNC display interface to see if it is set for continuous light, if not then change to continuous light.

2.Observe the display interface to see if there is a laser display and whether the number of lasers is normal when the table is running. After replacing the main board of the welding machine, observe whether it is normal, if still not light replacement light gate board.

Laser welding machine suddenly not out of light is what causes?

This is all we have to share. In fact, many times laser welding machine failure is not necessarily a problem with the machine itself, but improper human operation methods lead to, so this requires us to master the correct method of operation when using the laser welding machine, only then can avoid the occurrence of failure.

Laser welding machines in 6 modes

Handheld laser welding machines, also known as laser welding machines and laser welding machines, are a type of machine used when we use laser welding in the processing of materials. Laser welding is a new type of welding method for thin-walled, precision parts, capable of spot welding, stack welding, butt welding, sealing welding, etc.

In modern industrial production, laser welding machines are valued for their ease of operation, fast welding speed, good welding results, low welding consumables, high efficiency and greater environmental friendliness.

Depending on how the laser welding machine works, the application industry can be divided into handheld welding machines, advertising welding machines, mould welding machines, vibrating mirror welding machines, fibre optic transmission laser welding and so on. If you are struggling with what laser welding machine to choose, then follow the first moment to take a look at the application characteristics of various laser welding machines.

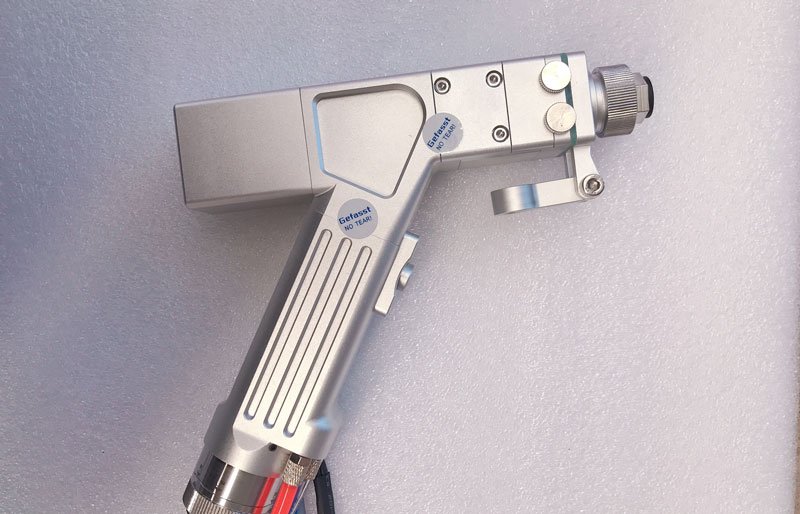

Handheld laser welding machine

The whole machine adopts integrated design and good interactive control system, which solves the disadvantage of small light spot and better welding seam forming. Usually beautiful and compact, flexible, more convenient to move and transport, so especially suitable for outdoor welding, like kitchen appliances, doors and windows guardrails, stairs and lifts, advertising frame, hardware sheet metal, rail transportation, etc.

Jewellery laser welding machines

When the machine was first developed and produced, its purpose was to weld gold and silver jewellery. When laser welding, because of the small welding joints, will not affect the original pattern of raw materials, but also do not need too much post-welding treatment, compared to ordinary welding with black circle to compare, jewellery laser welding machine to maintain the fine beauty of raw materials.

And with the development of market demand continues to change, jewellery laser welding machine due to accurate, and widely used in teaching colleges and universities laboratory platform, scientific research, military instruments, instruments, automotive processing, aerospace parts and accessories welding, almost all the need for manual welding of fine precision parts can be used jewellery laser welding machine for welding work.

Fiber laser welding machine

Its low power continuous fibre laser can be used in conjunction with a flow detector and long focal length lenses to form extremely small spot sizes for welding a wide range of thin plates at high speeds via remote locations.

Due to the excellent beam quality of the laser, the welding speed is fast and the weld seam is solid and beautiful; the high electro-optical conversion rate and low energy consumption allow continuous and stable processing for 24 hours, meeting the needs of industrial mass production processing and saving the user a lot of processing costs.

Advertising laser welding machine

Usually used in the metal advertising letter making industry, mainly for metal welding, the materials that can be welded are: stainless steel, brass, galvanised sheet, tinplate, white iron, cold rolled sheet, etc.

The laser beam is easily focused on a small area and is not affected by magnetic fields, allowing small, closely spaced parts to be welded. For welding thin materials or fine diameter wire, there is no risk of backfusion as in arc welding.

Mould laser welding machine

The large LCD display makes operation simple and easy to learn. Not only is the heat affected area small, the oxidation rate is low, and there are no sand holes or porosity, but the effect of repairing the mould is that there are no dents or bumps in the bond, and the mould will not be deformed.

Laser welding machine for moulds, precision injection moulding, die-casting, stamping, stainless steel and other hard materials, such as cracks, chipping, touching the edges and the loss of sealing edge repair, welding; so suitable for most materials of mould repair.

Laser welding machine for vibration mirror

For welding processes with high requirements and convenient optical paths, we can use the oscillator laser welding machine. It is capable of welding fine microelectronic components, succession circuit leads and other precision parts. It is characterised by high efficiency and can perform high frequency spot welding, but also has high power supply requirements.

Handheld laser welding machines re the faucet industry

Faucet is a popular name for a water valve. It is used to control the amount of water flow and has a water-saving effect. From the old cast iron technology to the electroplated knob type, to stainless steel single temperature single control taps, stainless steel double temperature double control taps and kitchen semi-automatic taps, taps are being updated at a very fast pace.

Nowadays, more and more consumers are buying taps where they will consider materials, features, shapes and other aspects.

In tap production techniques, welding is repeatedly required to join these small parts together. The construction of a tap is unique, especially when it comes to welding when turning, which is a difficult part of the welding process.

Traditional welding methods of welding can lead to leaking taps, so a welding method with good welding properties and a stable weld is required. Laser welding machines can meet these requirements.

The laser welding machine for stainless steel taps uses a high-energy pulsed laser. Non-contact object welding, solid welded workpiece, no cracks or porosity in the weld, no leaks or breakage in the weld on the faucet, stable performance and low failure rate.

The handheld laser welding machine is a new type of welding equipment. With its unique advantages of high precision and efficient welding, it has won the hearts of customers and has replaced traditional processing methods.

Developed and produced by the first engraving laser, the fibre laser welder machine is easy to operate and does not require a technician to operate. New employees can start working quickly, thus saving the company training time; the welding speed allows for automated operation and mass production.

Fish scale welding – the highest level of welding technology

Fish scale welding, which many people may not have heard of, is a welding process that is named after the fish scales that appear when welding a flat surface.

It is a visual impact on human beings, with its full surface and colourful and dynamic, it is a feast for the eyes, but the difficulty of welding fish scales is very high, so this welding technology is also recognized as the most advanced welding technology in the world.

When operating, the hand controlling the welding gun must be steady to avoid shaking hands and burning the dock pole causing tungsten trapping in the molten pool; the wire transport also requires good technique and is chosen according to the size of the break, with the wire being placed in the middle of the pool for continuous feeding when the break is small.

This usually requires a good deal of skill to avoid touching the docking electrode so that the torch can move from side to side in order to make the edges fuse well.

Current is also critical, as a low current will tend to fail to fire and cause the rod to stick to the weld.

If the current is too high, it will easily burn through and cause deformation of the weld.

Therefore, it is not easy to produce a good-looking fish scale weld. In addition to mastering the relevant skills, you must also practice your welding skills diligently so that you can produce a wonderful fish scale weld.

What are the latest laser welding machine prices?

There are many different brands of metal laser welding machines on the market today. If you want to know how much the latest handheld laser welding machine costs, the first step is to understand your current welding needs. For example, what is the material to be welded? What is the thickness of the material to be welded? What are the requirements for welding efficiency?

The answer to these three questions is clear, and then you can determine your own needs to choose the right equipment power. Because of the handheld laser welding machine models, prices range from tens of thousands to hundreds of thousands, or even millions, so be sure to pay attention to the manufacturer’s equipment quality, pricing, equipment commissioning, on-site teaching and after-sales issues, are very important.

So it is recommended that when you buy handheld laser welding equipment, it is best to clear their own needs, door-to-door inspection of manufacturers to see the scale, equipment and the use of the effect.

The most advanced welding method for gear laser welding technology

Laser welding technology is currently the most advanced welding method in the field of processing. In contrast to conventional welding technology, laser welding technology is non-contact welding. No pressure is required for the operation process. With high welding speed, high efficiency, large depth, small residual stress and deformation, laser welding technology can weld refractory materials such as high melting point metals, and can even be used to weld non-metallic materials such as ceramics, organic glass, etc. The welding of shaped materials is effective and flexible.

For difficult to weld parts, non-contact welding with flexible transmission can be used. The laser beam can separate light in time and energy and can handle multiple beams at the same time, which provides for more precise welding.

Due to its high power density and rapid release of energy, laser welding is more efficient than conventional methods when it comes to process efficiency. Laser welding processes have superior processing characteristics to conventional processes. Laser welding uses high-energy laser pulses to locally heat the material in a small area.

Portable handheld laser welding machine

The portable handheld laser welding machine has the characteristics of fast welding speed, high efficiency, good welding effect, low welding consumables, long life and environmental protection, which can be widely used in kitchen appliances, doors and windows guardrails, stairs and lifts, stainless steel furniture, hardware sheet metal, advertising signs, craft gifts, car repair, automobile manufacturing, rail transportation and aerospace industries welding.

At the same time, this small handheld laser welding machine is marked with a wire distribution machine, which can reduce the clearance requirements of the parts and make the welding quality further improved. And it can also be used with collaborative robots, fixing the welding gun on top of the collaborative robot, reducing the operator’s labour intensity and improving the quality of the weld.

Good results

Handheld laser welding with a dexterous internal design and a good interactive control system, which solves the disadvantage of a small light spot and results in better weld seam formation.

More lightweight

The laser welding gun is lightweight and ergonomically designed for a comfortable grip; it is easy to control with one hand and simple to use.

Safer

The welding gun has multiple safety alarms and automatically locks the light when the workpiece is removed for safety; beautiful welds, high speed, no consumables, no weld marks, no discolouration, no need for post-polishing.

Many options

For various needs such as external welding, internal welding, right angle welding, narrow edge welding and large spot welding of metal parts, the welding nozzle of the small handheld laser welding machine has a variety of angular nozzles to meet the welding needs of different products.

Conventional laser welding equipment

Conventional laser welding equipment Resistance welding or argon arc welding is usually used. The disadvantage of resistance welding is that it can easily lead to deformation of the workpiece, and resistance welding requires welding through both sides of the joint.

Argon arc welding, on the other hand, uses non-consuming electrodes and shielding gas and is usually used to weld thin workpieces. However, its disadvantages are that the welding speed is slow and the heat input is much greater than that of laser welding equipment, which also tends to lead to distortion.

This is also the reason why traditional welding machine equipment requires high technical requirements for the operator, and after using traditional welding, the workpiece has to be polished, which not only seriously affects the work efficiency, but also polishes the workers in a long-term flying chip dust environment, which is also easy to cause harm to the human body.

What are the advantages of handheld laser welding machine?

1, handheld laser welding machine is a new generation of laser welding products, compared to the traditional use of gas welding and argon arc welding, the use of laser welding weld more flat and smooth, almost no grinding later, greatly reducing the cost of labour;.

2, traditional welding on the technical requirements of high, while handheld laser welding machine for the welding machine technology requirements are lower, easier to get started, even if no operating experience through a short period of training, you can also quickly on the job.

3, welding speed compared to traditional welding equipment, its welding speed 2 to 5 times faster, greatly improving the production efficiency of enterprises.

4、Handheld laser welding equipment is flexible in operation and more suitable for outdoor work: it can carry out all kinds of flat welding, fillet welding, stack welding and other welding methods.

5、Because of the fast welding speed and good welding effect of handheld laser welding, the welding consumables are less, more efficient and longer life compared to traditional welding equipment.

6, mobile transport is also more convenient, for the need for precision welding needs can be perfectly met.

How to solve the weak light from industrial laser welding machine?

In recent years, laser welding machine equipment has occupied a place in industrial welding due to its stable performance, reliable use, fast welding speed, wide welding range, long life of consumables and other characteristics.

When we encounter laser welding equipment out of the light is very strong at the beginning, and then gradually become weak (light weak), and eventually lead to the inability to melt the wire or sparks at the copper mouth, then how do we solve it?

Analysis of the reasons for the appearance of weak light.

Usually this situation, generally are welding gun lens damage, including not limited to protective mirror, focus, collimation, reflection, etc., any one or more of these damage may cause the weak light situation.

1, first replace the protective mirror and look at the focus, and then to check the reflection and collimation, replace the damaged lens can be.

2, if the above checks are completed, you can then check the laser fiber head position for dirt or damage.

Damage to the lens analysis.

- classification of damage: abnormal motor oscillation due to interference, or unadjusted red light that is too biased, and in general the seals will burn together.

- damage to the convex surface of the lens: generally common to pollution, such as replacement without protection, in the form of dotted black spots.

- damage to the plane of the lens: due to diffuse reflection of the laser, mostly caused by reflection, which creates a focus on the lens and burns the coating, in the form of white spots. Convex surfaces also have this morphology and are formed on the same principle.

Lens fault treatment: replacement of the damaged lens.

Follow-up on how to avoid.

In hand-held laser welding, the lenses are usually replaced with the highest frequency, and generally for the causes of damage, we can carry out relevant preventive measures.

- the use of original lenses.

- pay attention to anti-pollution when replacing them.

- techniques try not to weld vertically, especially when welding highly reflective materials.