- OEM ODM cnc best metal laser cutter for small business

wholesales china sheet metal laser cutter machine manufacturers

We are a wholesaler of OEM ODM sheet metal laser cutter machine in China. If you need to find reliable quality and affordable cnc laser cutter for metal price, SUNSHAN will be one of your reliable providers.

Our Hot CNC sheet metal laser cutter for sale

china sheet metal laser cutter (Optional)

1. Sheet metal laser cutter power: 1000W, 1500W, 2000W, 3000W, 4000W, 6000w, 10000w, 12000w, etc.

2. Fiber laser generator: JPT, RAYCUS, MAX, NIGHT, IPG etc.

3. CNC sheet metal laser cuttermaterials: Iron, aluminum, carbon steel, stainless steel, copper, hardware and another metal sheet materials.

4. Other machine optional parts can be chosen, such as, rotary axis, exchange working table, full cover, etc.

5. China Top fiber laser machine cutting manufactuers, JNLINK, best price and high quality, with CE etc certificates.

Parameter of CNC laser cutter for metal

| Model | 3015G/4015G/4020G/6015G/6020G CNC sheet metal laser cutter |

| Working Area | 3050*1525/4050*1525/4050*2020/6050*1525/6050*2020 |

| Laser Power(kw) | 1.5/2/3/4 |

| Maximum Speed(m/min) | 80 |

| Maximum acceleration(g) | 0.8 |

| X/Y Axis positioning accuracy(mm/m) | ±0.05 |

| X/Y Axis repeated positioning accuracy(mm) | ± 0.02 |

CNC laser cutter for metal Features:

1. High-performance laser device associated with stable operation system enables optimal cutting effects.

2. Perfect cooling, lubrication and dedusting systems ensure stable, efficient and durable performance of the whole machine.

3. Single countertop make plates loading and unloading available during cutting, which improves the processing eficiency.

4. Large-size closed enclosure improves dedusting effects and avoids optical pollution.

5. Automatic height-adjustment performance keeps constant focal length and stable cutting quality.

6. Gantry structure and inblock aluminum cast cross beam make the device highly rigid, stable and antiknock.

7. It could ut mental in various materials and realize excellent and stable cutting effects.

Auto-focus laser head

The laser head is made of high quality materials in accordance with advanced technology. It is strcng and curable it can achieve ‘onine’ measure ment during the production process, and the measurement is accurate and rapid

Cypcut plane control system

industry,easy to use, rich in functions, suitable for various processing occasions.

Edge finding aid

Dual-drive deviation self-correcting two-stage capacitive edge seeking

Yaskawa servo motor and driver

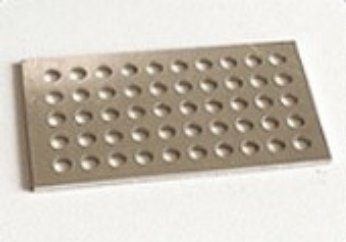

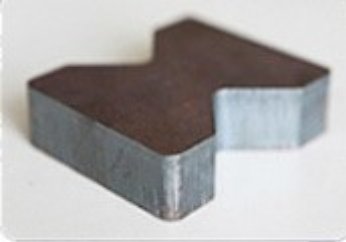

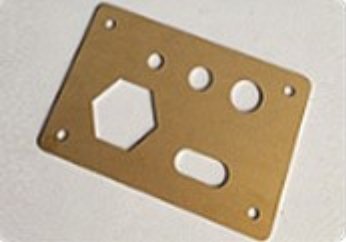

CNC Metal Fiber Laser Cutter Products

Fiber Sheet Metal Laser Cutting Equipment is suitable for metal cutting like Stainless Steel Sheet, Mild Steel Plate,

Carbon Steel Sheet, Alloy Steel Plate, Spring steel Sheet, Iron Plate, Galvanized Iron, Galvanized Sheet, Aluminum Plate, Copper Sheet, Brass Sheet, Bronze Plate, Gold Plate, Silver Plate, Titanium Plate, Metal Sheet, If you equipped with the rotary axis, Metal Plate, Tubes and Pipes, all ok.

What is this sheet metal laser cutter machine Used for?

The 3015 metal sheet laser cutting machine is used to cut mild steel, stainless steel, aluminum alloy, brass and other steel; Application in automobile industry, sheet metal industry, furniture industry, advertising industry, etc.

CNC Fiber Laser Cutting Machines are widely used in manufacture Billboard, Signs, Advertising, Signage, Metal Letters, LED Letters, Kitchen Ware, Advertising Letters, Sheet Metal Processing, Metals Components and Parts, Ironware, Chassis, Racks & Cabinets Processing, Metal crafts, metal art ware, elevator panel cutting, hardware, auto parts, Glasses Frame, Electronic Parts, Nameplates, etc.

China laser sheet metal cutter wholesale

Working in laser sheet metal cutter industry for more than ten years. Provide complete customization service of custom metal laser cutting machine according to customer’s needs and requirements.computerized the best metal cutting machine for you.

Metal Fiber Laser Cutter Related Products

Questions about CNC metal laser cutter

Metal laser cutter price has always been more concerned about the customer, sometimes the price feels right, before the configuration aspect of the consultation, where the general give out is a standard machine base price, how much is a metal laser cutting machine? Is the machine with other equipment with the configuration of the price, is based on your product needs to you with. Some customers ask how much a laser cutting machine. Also with automatic loading and unloading device, is to buy all at once, buy back to use directly to produce products.

First of all, we need to understand what materials can be cut by laser cutting machine, statistics about the role of metal there are so many kinds: common metals are stainless steel, carbon steel, manganese steel, not common galvanized sheet, a variety of alloy plates, rare metals, etc..

In general, it has a wide range of metal role, generally as long as the material is not particularly high-reflective nothing pressure, of course, high-reflective material can also be, but very waste lenses, some people say hurt the laser, this is not right ha, the cutting part is the laser head, the laser is not cutting on the metal, that is called the cutting head, the laser is like a computer chassis like the device.

Stainless steel as a common material in laser cutting machine cutting is not a cutting problem, the only thing customers need to be clear is to cut how thick the stainless steel is the key, the cliché is that the thickness of the power is related, there is also the size of the stainless steel material, some of the intake channels or product size is not the same.

Many manufacturers are buying a certain size of stainless steel plate, so the size of the plate for the metal laser cutting machine width also has a relationship, here there is the problem of non-standard cutting machine, customer requirements are often standard models can not reach, either the width of small, or large, or a variety of other small problems, so the general process is the designer according to customer needs to draw drawings and then processing production, this non-standard models and the price is not the same.

So in general, the price of stainless steel laser cutting machine, how much to a I can only say here, the standard machine of low-power laser cutting machine is about 20-30,000 U.S. dollars between the medium power laser cutting machine is about 50-100,000 U.S. dollars between the high-powered 10,000 watts fiber laser cutting machine is afraid of more than 300,000 U.S. dollars, so the choice is very important.

China as a big manufacturing country, Made in China has become a synonym of quality. Especially in the field of metal processing, due to the rapid development of the metal products industry, the number of enterprises is also growing year by year, and the competition between industries is getting bigger and bigger. As the owner of metal processing industry, many times face the trouble of insufficient manpower in the peak season of production and idle labor in the off-season of production. The lack of labor and low production and processing efficiency have become the key to restrict the development of metal processing enterprises.

The main metal processing processes include cutting, stamping, bending, welding and so on, and metal cutting as the first process of metal forming, its efficiency and quality will have an important impact on the next processes. In the past, often use flame cutting, plasma cutting and other processing methods, because of the accuracy and speed of the relationship, gradually eliminated by the market, slowly laser cutting has become the mainstream of metal processing methods.

1, the thickness of the material: usually I do use the thickness of the two commonly used materials as the main basis for selecting the laser power.

Usually we refer to the 1000W-6000W under the laser cutting machine called low-power laser cutting machine, 6000W-15000 called high power this time the laser cutting material thickness range is.

1000W power laser cutting machine cutting carbon steel thickness: 0.8-10mm; cutting stainless steel thickness: 0.8-5mm

1500W power laser cutting machine cutting carbon steel thickness: 1-16mm; cutting stainless steel thickness: 1-6mm

2000W power laser cutting machine cutting thickness of carbon steel: 1-20mm; cutting thickness of stainless steel: 1-8mm

3000W-3300W power laser cutting machine cutting carbon steel thickness: 1-22mm; cutting stainless steel thickness: 1-10mm

4000W power laser cutting machine cutting carbon steel thickness: 1-25mm; cutting stainless steel thickness: 1-15mm

6000W power laser cutting machine cutting carbon steel thickness: 1-30mm; cutting stainless steel thickness: 1-20mm

8000W power laser cutting machine cutting carbon steel thickness: 1-40mm; cutting stainless steel thickness: 1-30mm

10000W power laser cutting machine cutting carbon steel thickness: 1-45mm; cutting stainless steel thickness: 1-40mm

12000W power laser cutting machine cutting carbon steel thickness: 1-50mm; cutting stainless steel thickness: 1-45mm

15000W power laser cutting machine cutting carbon steel thickness: 1-60mm; cutting stainless steel thickness: 1-50mm

The above is the cutting thickness of 1000W-15000W, maybe not very accurate, but it is also eight or nine.

Good or bad use of stainless steel laser cutting machine is not only the quality of the product, there are operators and usually maintain the equipment and other factors related to the manufacturer’s training services and the use of manufacturers trained personnel between the issues.

Stainless steel laser cutting machine is not able to cut their own, it is not fully automatic, it is necessary to draw, and then for different materials to adjust different parameters to cut steel, in general the training is the basic operation, drawing this is the need for buyers to draw their own, the need for the foundation of CAD to work, about debugging words may not be good, after all, a training a debugging master fast six months slow year, so the general situation is to set the parameters of the operator and the usual maintenance factors related to the problem. So the general situation is to set the parameters, simply teach a little fine-tuning.

Carbon steel is better than stainless steel cut, 6000W power can probably cut the stainless steel 20mm, but! Here is a but, this is basically the limit of cutting, cutting 18mm-20mm stainless steel on the material factors, so it is not recommended 6000W dry to 20mm, the safety value is 16mm. so to cut thicker recommended the use of higher power.

Some metal fiber laser cutter manufacturers have higher prices, the external publicity is good quality, some cheaper, there are those who say it is poor quality, in fact, there is no inevitable relationship.

Something expensive to determine the cost, 15,000 U.S. dollars of things want to use 30,000 U.S. dollars of features is obviously self-deception, of which the manufacturing of the bed in several ways, pipe welding and sheet metal welding, pipe welding cheap, sheet metal welding expensive, such as your machine 30,000 U.S. dollars, you think it’s too expensive to be 20,000 less.

So good, sheet metal welding to pipe welding, the bed strength although said enough, but in case the user does not know the limit of tolerance, navigation hanging some heavy objects up directly collapsed very embarrassing, so customers in the selection of the main these small details, sheet metal welding is a little more expensive is normal. Small metal laser cutting machine on this aspect of okay, mainly for large format.

With the continuous development and progress of industrial manufacturing, the application of stainless steel has been very extensive. In household products, electronic appliances, transportation, construction materials, industrial machinery and other fields have been used accordingly. Stainless steel is composed of steel containing less than 1.2% carbon and more than 10.5% chromium, which itself is famous for its difficulty in rusting and high corrosion resistance.

Stainless steel processing in the current basic to laser cutting, laser cutting technology is the use of fiber laser beam on the surface of the material small-scale action, the laser beam high-density high energy on the stainless steel plate local heating, evaporation effect area, so as to achieve the cutting of stainless steel.

Stainless steel laser processing has a variety of focusing methods, commonly used focus mirror direct focus and vibration mirror plus flat field mirror two, which vibration mirror plus flat field mirror combination and processing speed, the advantages of a wide range of applications are widely used. This focusing method does not require a laser light source, and can be equipped with a variety of wavelengths, pulse width types of lasers. The type of material processed is mainly thin plates, such as stainless steel, carbon steel, aluminum and composite metal plates.

For some manufacturers who use stainless steel as the main component, the use of laser cutting stainless steel is currently a faster and more efficient processing method. In the process if you can have strict requirements on the parameters, you can maintain the good corrosion resistance of such materials. The most important process parameters that affect the quality of stainless steel cutting are cutting speed, cutting accuracy, laser power, air pressure, etc.

1, in the case of setting a variety of process parameters to ensure good linear cutting effect, cutting corners will be excessive ablation, so that the corner quality is reduced; especially small angle cutting, due to overlapping cutting paths, resulting in concentrated laser energy, resulting in corners will generally be excessive ablation; in order to ensure the overall cutting quality, in different locations to set different parameters for cutting, the parameters are more cumbersome to modify.

2, in setting a variety of process parameters to ensure that the cutting effect is very good, often in the cutting part of the beginning of the phenomenon of imperviousness, but also lead to overheating deformation of the surrounding plate.

Stainless steel is one of the most common metals in industrial manufacturing, fiber laser cutting machine can adapt to a variety of stainless steel plate cutting process. It has good cutting quality, not easy to cut through the phenomenon, the plate heat dissipation is uniform, not easy to over-burn phenomenon, save the use of protective gas, effectively reduce the cost of cutting, with safe and reliable, small failure rate, high cutting effect, good precision effect advantages.