China Handheld Fiber Laser Welding Machine Manufacturers

13 years china handheld fiber laser welding machine manufacturers & suppliers experience, provide the most affordable hand held fiber laser welding machine prices, serve 60+ countries and regions, professional technical training, and fast delivery,and provide you with the cheapest handheld laser welding machine cost

China Fiber Handheld Laser Welding Machine For Sale

The handheld fiber laser welding machine uses a new generation of fiber lasers to fill the gap in handheld welding in the laser equipment industry. It has the advantages of simple operation, beautiful welds, fast welding speed, and no consumables. It is used in thin stainless steel, iron, aluminum and other metals. In terms of material welding, it can perfectly replace the traditional argon arc welding and electric welding process.

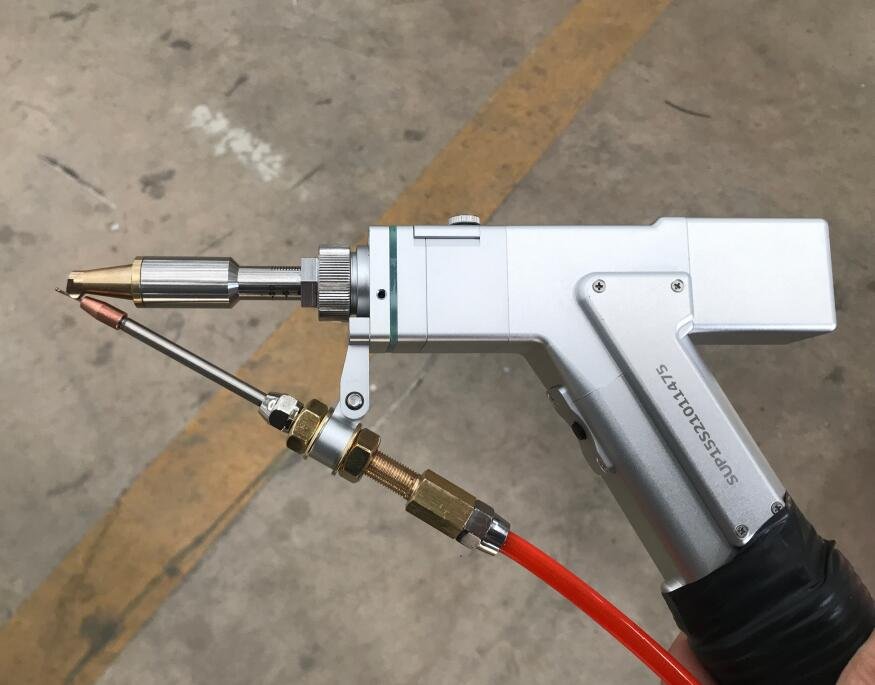

handheld laser welder for sale

Industrial Stainless steel, aluminum plate, carbon steel lightweld 1500 laser welding machine price for sale

fiber laser welding machine handheld Video

The welding speed of CNC fiber handheld laser welding machine is 3-10 times that of traditional argon arc welding and plasma welding. The welding heat affected area is small, and it will not cause problems such as deformation, blackening, traces on the back of the joint construction, and the welding depth is large, the melting is sufficient, and the welding is firm.

china cnc laser welding machine Specification

keywords | Industrial laser welding machine for sale |

Laser Power | 1000w/1500w/2000w |

Applicable Materials | Stainless steel, carbon steel, copper, aluminum etc. |

Materials Thickness | 0-5mm |

Output Power Stability | ±2% |

Fiber Optic Length | Fiber Optic Length |

Laser Wave length | 1070nm |

Working Temperature | 15-35℃ |

Weight | 280kg |

Specified voltage | 220V/380V |

| 1000W | 1500W | 2000W | |||

| Stainless steel | 2 mm | stainless steel | 3 mm | stainless steel | 4 mm |

| Galvanized sheet | 2 mm | Galvanized sheet | 3 mm | Galvanized sheet | 4 mm |

| Carbon steel | 2 mm | Carbon steel | 3 mm | Carbon steel | 4 mm |

| Aluminum | 1.5 mm | Aluminum | 2.5 mm | Aluminum | 3.5 mm |

The welding penetration of fiber laser welding

- Laser wavelength: 1064nm

- Pulse width: 15ms

- Laser frequency: 50HZ

- Spot range: 0.3-3mm

- Travel of automatic worktable: X=300mm Y=200mm

- Moving speed of worktable: <=100mm/s

- Control system: CNC

Handheld Laser Welding Machine Effect

Hand held laser welding machine for sale is an affordable, easy-to-use, and versatile tool that can help you begin a new start-up venture or increase the profits of your well-established company. This type of laser handheld welder is suitable for cutting stainless steel, carbon steel, alloy steel, spring steel, copper plate, aluminum plate, gold, silver, titanium ect., and has been widely used in advertising, high pressure / low voltage electrical cabinet production, textile machinery accessories, kitchen appliances, cars, machinery, elevators, electrical accessories, spring coil pieces, metro line parts and other industries.

stainless steel laser welder

handheld fiber laser welding machine for metal

aluminum laser welder

Hand held fiber laser welding machine welding a thickness:

1. 1000w handheld fiber laser welding machine can weld 0.5-2mm steel;

2. 1500w hand held fiber laser welder is used for welding 0.5-3mm steel;

3. The 2000w/2kw hand held fiber laser welding machine can weld 0.5-4mm steel and 0.5-3mm aluminum.

The above data is based on a triangular spot.

Due to the difference between plates and labor, the actual data shall prevail

Handheld laser welder there are 6 welding modes and multiple welding nozzles to meet different welding needs; hand laser welder has a safety sensor function, which emits a laser after touching the metal and automatically locks the light when it is removed; the spiral jitter function, the width of the weld can be adjusted, and the welding ability is significantly improved.

After the laser beam is focused, a small spot can be obtained, which can be accurately positioned, and is applied to micro and small workpieces that are automatically produced in large quantities. Mainly for the welding of thin-walled materials and precision parts, it can realize spot welding, stitch welding, tailor welding, sealing welding, etc. High aspect ratio, small weld width, small heat aff.

Applications of the fibre laser welding machine

Handheld fibre laser welding machines are widely used in industries such as machinery manufacturing, moulds, battery manufacturing, gears, lift manufacturing, household appliance manufacturing, communication equipment, aerospace, craft and gift, IT industry, medical equipment, automotive shipbuilding, etc.

traffic vehicles

agricultural machinery

gearboxes

Mould industry

machinery industry

construction machinery

The hand held welding machine uses the latest generation of laser sources. It is equipped with a special, laser-developed laser discharge head designed by the manufacturer for faster and easier operation.

Easy operation, beautiful weld seam, faster process, no raw materials required. For welding of stainless steel, ferrous metal, galvanized sheet, etc., laser equipment can replace the usual welding methods – argon, electricity, etc. Handheld laser welding machine for stainless steel can be used in almost any area where metal welding is required The handheld laser welding machine for stainless steel can be used in almost any field where metal welding is required.

1. 12 languages 24 hours Quick Feedback;

2. “Training Video”, “Instruction Book”, and “Operation Manual” will be offered;

3. Brochures for simple trouble-shootings of the machine is available;

4. Plenty of technical support online is available;

5. Quick Back-up Parts Available & Technical Assistance;

6. Free training service is available.

Best china handheld fiber laser welding machine suppliers

At our company, you are sure to find quality, practical and durable handheld laser welding machines, which we can supply worldwide at very low prices.

Related Products

Handheld Laser Welding Machine Questions Collection

Industrial handheld laser welding machines can be used to weld stainless steel, carbon steel, aluminium, copper, chrome, nickel, titanium and other metals or alloys.

At present, the field of metal welding, handheld laser welding machine is widely used, basically the traditional welding can be welded metal, laser can do welding, and welding effect and speed will be better than the traditional welding process. Traditional welding is difficult to weld non-ferrous materials such as aluminium alloys, while laser welding has a broader application, and materials such as aluminium alloys can be easily welded.

Difficulties with aluminium laser welder

Aluminium alloy features: light weight, non-magnetic, good low temperature performance, good corrosion resistance, good formability, etc. The weight of aluminium alloy can be reduced by half instead of steel plate welding.

Although aluminium alloy has many advantages, it is also more troublesome to handle, because the thermal conductivity of aluminium alloy is large (about 4 times that of steel), and the heat input is 2 to 4 times larger than that of welded steel at the same welding speed. Therefore, the welding of aluminium alloys requires an efficient welding method with high energy density, low welding heat input and high welding speed.

laser welding machine for aluminium5 points to note

1, aluminium alloy welding is prone to porosity.

2. The large coefficient of linear expansion of the weld, which can easily lead to welding deformation.

3、Aluminium alloy welding is easy to produce thermal cracks.

4、Serious softening of the welded joint of aluminium alloy and low strength coefficient, which is the biggest obstacle to the application of aluminium alloy.

5、The surface of aluminium alloy is prone to produce refractory oxide film (A12O3 whose melting point is 2060°C), which requires a high power density welding process.

Many friends did not understand the shielding gas of laser welding machines when they bought the laser welding machine. In fact, the physical and chemical properties of laser welding are different. The shielding gas mainly includes N2, Ar, He. The effect on the weld is also different.

Nitrogen N2—can be used for welding shielding gas for stainless steel

The ionization energy of N2 is moderate, higher than that of Ar and lower than that of He. Under the action of the laser, the ionization degree is average, which can reduce the formation of a plasma cloud and increase the effective utilization rate of the laser. Nitrogen can chemically react with aluminum alloy and carbon steel at a certain temperature to produce nitrides, which will increase the brittleness of the weld, reduce the toughness, and have a greater adverse effect on the mechanical properties of the weld joint. Therefore, it is not recommended to use nitrogen. Aluminum alloy and carbon steel welds are protected.

The nitride produced by the chemical reaction between nitrogen and stainless steel can increase the strength of the weld joint, which will help improve the mechanical properties of the weld. Therefore, nitrogen can be used as a shielding gas when welding stainless steel.

Argon Ar-cost-effective, the most conventional protective gas

The ionization energy of Ar is relatively low, and the ionization degree is high under the action of laser, which is not conducive to controlling the formation of plasma cloud, and will have a certain impact on the effective utilization of laser. However, the activity of Ar is very low and it is difficult to chemically interact with common metals The cost of Ar is not high. In addition, the density of Ar is higher, which is beneficial to sink to the top of the weld pool, and can better protect the weld pool, so it can be used as a conventional shielding gas.

Helium He—the best but also the most expensive protective gas

He has the highest ionization energy, and the ionization degree is very low under the action of laser, which can well control the formation of plasma cloud. Laser can act on metal very well, and He has very low activity and basically does not chemically react with metal. It is a good shielding gas for welding seams, but the cost of He is too high. Generally, mass production products will not use this gas. He is generally used for scientific research or products with very high added value.

Everyone knows that the handheld laser welding machine is assembled from many different parts, and the laser head is one of the most important parts. In the long-term use, the laser head of the handheld laser welding machine will definitely suffer from a certain loss, so how to reduce the loss of the welding head of the handheld laser welding machine in daily use.

How to reduce the loss of the welding head of the Shenzhen laser welding machine in daily use:

1.Clean the laser head.

The laser head should be cleaned regularly. Don’t let some dirt affect the welding quality and effect. If the laser head is not clean, then the laser energy will be affected when the laser is emitted when using a handheld laser welding machine. , This will cause some impurities when the laser is emitted, which will make the transmission of the light unstable and lower the quality, which will affect the transmission of the light.

2.The laser head should be inspected regularly.

Once it is found that there is a problem with the laser head, it should be replaced and repaired in time to avoid affecting production. The protection of the laser head should be done from daily use. Usually, these details are not paid attention to, and it takes a long time. If there is a problem, the life of the laser head will be reduced. Regular cleaning and maintenance of it can extend the life of the laser welding machine.

The above is the main content of how to reduce the loss of the welding head of the handheld laser welding machine in daily use. In fact, there will be a certain loss as long as you use it anyway. This is a normal phenomenon. You don’t need to worry too much, as long as we add more maintenance!

1. The protective gas is opened too much

Solution: adjust the airflow of the protective gas

2. The focusing lens is damaged or contaminated

Solution: Replace or clean the focusing lens and protective lens.

3. The laser is not output from the center of the copper gas nozzle under the focusing head

Solution: adjust the 45-degree reflective diaphragm to make the laser output from the center of the gas nozzle

4. The diaphragm of the laser cavity is damaged or contaminated

Solution: Replace or clean the reflective diaphragm of the resonant cavity.

5. The shutter did not fully open

Solution: Check and add lubricating oil on the shutter connecting parts to make the connecting parts mechanically smooth

6. The service life of the xenon lamp is up

Solution: Check and clean the old lamp or replace with a new xenon lamp.

7. The cooling water is polluted or the cooling water has not been replaced for a long time

Solution: Replace the cooling water and clean the UV glass tube and xenon lamp

8. The defocus of the focusing lens is too large

Solution: adjust the amount of defocus to be close to the focus position (but there should be no splashes)

9. Laser deviation of the main optical path

Solution: adjust the main light path full-reflection and half-reflection diaphragms, use photo paper to check and adjust the round spot

Application fields of laser welding machine:

Auto and parts industry, motorcycle and electric vehicle industry, machinery industry, pressure vessel, boiler manufacturing, hardware processing and other installation methods. Robots can choose to lay flat on the ground, side hanging, upside down and other installation methods. External expansion can be based on user needs. Perform coordinated work of multiple robots or add external axis positioners and walking rails.

The above is the main content of the solutions to common problems of laser welding machines. I believe you will have a new understanding of the troubleshooting methods of laser welding machines after reading!

The handheld laser welding machine is a precision instrument, which has certain requirements for the space environment where it is placed. And many manufacturers have encountered unexplained equipment efficiency degradation or even damage, these are due to the placement of the handheld laser welding machine storage or in the process of using the process of not paying attention to environmental issues, so how to change the placement of the handheld laser welding machine?

Pay attention to the following when using or placing the handheld laser welding machine:

- Do not place the handheld laser welding machine in an environment where the space temperature exceeds 0 ℃-50 ℃, and the space humidity exceeds 10%-90%;

- The handheld laser welding machine is not suitable for places where the weather and temperature change in a short period of time;

- Outdoors where there will be condensation and direct sunlight; avoid placing fiber laser welding in such places to prevent uncertain factors from occurring.

- The handheld laser welding machine must not be placed in places where there is too much dust or dust. This needs to be paid attention to. Many manufacturers have low production efficiency due to dust and dust;

- The handheld laser welding machine should not be placed in an unstable and susceptible to vibration; because the internal parts of the welding machine are very precise and easy to be shaken, so in order to avoid this situation, do not place it in this place.

In short, when we use it, we must keep in mind that the handheld laser welding machine is a precision instrument, and we must pay attention to the environment and keep it properly.

Remember not to place it at will. After all, the equipment is purchased at a high price. If you send it back to the manufacturer for repair, even if you don’t need the money, it will delay the construction period of the factory, and it may seriously affect the work efficiency.

Metal laser welding machine process less from the embodiment of what?

Compared to the old days, this era is now developing extremely rapidly, and there is a qualitative leap in the excellence of each industry. In the traditional welding equipment, each device almost all have good welding quality, welding materials and other advantages, but the metal laser welding machine in this new era, with one of the biggest advantages that is the welding process less, through the metal laser welding machine welding out of the material are not easy to deformation, so there is no need to deal with too much, can be completely straightforward to eliminate the polishing and leveling process, for It is also very convenient for the staff.

Laser welding is an extremely important project in laser processing, and is an advantage that cannot be replaced by traditional welding equipment. There are many tools in our lives that have been processed by laser welding, such as kitchen tools, electrical appliances at home, more sophisticated cabinets, lifts and even motors for new energy vehicles, among other related applications. These are all examples of how laser welding plays a very important role in our lives. Metal laser welding machines offer a lot of help with the problem of less processes.

When it comes to metal laser welding machines, it has to be said that the materials to be welded are really not limited. The laser beam emitted by the metal laser welding machine can dissolve different types of metal materials very quickly, even if the traditional welding machine is difficult to weld, for the laser welding machine has been easily dissolved. Because of this factor, laser metal welding machines are superior to traditional welding machines and can be used in a variety of industries to maximise their performance.

Last but not least, the non-contact welding method is a special feature of metal laser welding machines. For traditional welding equipment, it emits a lot of heat when welding workpieces and requires the staff to be in close contact with the workpiece, which may result in the welding equipment having too large a contact point, affecting the quality and even the aesthetics of the product itself.

This is not the case with the handheld fiber laser welding machine for metal, which is a great improvement in this respect. It uses laser welding technology to complete the welding work without close contact with the workpiece, and it is extremely fast and perfect, which is a greater guarantee for the aesthetics and quality of the staff or the product.

With the above, the handheld fiber laser welding machine for metal will receive more “favour” from manufacturers for its low process and the guarantee of quality and aesthetics. The handheld fiber laser welding machine for metal can be used in a far wider range of applications than traditional laser welding plants, so it is a better choice for laser welding machine manufacturers.

4 aspects of metal laser welding machine to determine the welding effect?

In today’s society, metal laser welding machines occupy a very important part of the relevant field. As a consumer, the most important thing to worry about is the quality of the welding, and how to judge this? I think there are four aspects that should be judged.

First of all, to accurately judge the welding operation process melting phenomenon, for such an operation process melting phenomenon generated by the strength of the degree, but also depends on the composition of a variety of factors. For example, the time the laser acts on the surface of the material, the power density and the peak power. These factors can be controlled to allow a variety of welding processes to be carried out using the laser. Another factor is the most critical in the welding process of a metal laser welding machine – the beam focus position. The beam focus position is one of the most important factors, as the laser power and welding speed are the relevant factors, and when the focus is in the optimum range it will provide the maximum depth of melt and a good weld shape.

Secondly, the most important thing to know about the welding results is to be familiar with the welding method of the metal laser welding machine. There are two common types of laser welding.

The first is the pulsed laser welding, which is nowadays mainly used for single point fixed continuity and welding of thin materials, making them into a single circular joint;

The second is called continuous laser welding, which is mainly used in the welding and cutting of large thick parts, gradually forming a continuous weld during the welding operation. It is not only the understanding of the laser welding method, but also the need to understand the choice of basic welding materials and the choice of metal laser welding machine and the choice of processing table, all of which affect the effect of laser welding. So before judging it, you also have to stock up on the knowledge associated with it before you can make any progress.

This is closely followed by the selection of the frequency of the metal laser welding machine. In the use of metal laser welding machine, its staff will be adjusted according to the requirements of customers for the efficiency of metal laser welding machine above, adjusting its frequency parameters is mainly used to improve welding efficiency, especially in the face of some delicate metal laser welding, with its mirror and scanning system, the role of frequency will play a greater role. For how to adjust to the right frequency will be a technical problem, and at the same time with other aspects are also related, so only to make the overall effect of enhancing the ultimate to get the perfect welding effect.

Finally, the tensile strength of the handheld fiber laser welding machine for metal is monitored. When the machine is working, it is tested to see if its ability to develop tensile strength meets our needs, and the results of the inspection are used to judge the effectiveness of the welding. In the event of a bad weld, etc., it is important to consider a number of factors and to start with the essence rather than the surface. It may not necessarily be a fault with the welding machine, but also the choice of material, so you should either change the material immediately or change the data of the handheld fiber laser welding machine for metal waveforms and weld again, and then evaluate the results again.

Only after familiarising yourself with these aspects will you know how the welding results of a handheld fiber laser welding machine for metal can be identified. Of course, everything needs to be carried out in the field and patiently as a whole, and having knowledge about it can only be beneficial.

Good equipment makes good products. This phrase could not be more appropriate for laser welding machines. But laser welding machine china manufacturers often encounter such customers, and others and the same model of laser welding machine, but the quality of welding out of others, in fact, it is not surprising, after all, for any equipment, there are many factors that affect the quality of products, especially external factors. Today we will understand what factors affect the quality of handheld laser welder.

1, the welding process parameters

Different laser welding machine has different process parameters, some of which will have an extremely intuitive impact on the quality of welding, these factors are mainly power density, pulse waveform, pulse width, the impact of defocusing, etc., friends should better consider these related content.

2, the case of the workpiece fixture

In the use of good reputation laser welding equipment for welding process, fixed workpiece fixture will also have a certain impact on the quality of welding. Workpiece fixture is mainly used to tighten the welded workpiece is accurate positioning of the welded workpiece in order to facilitate the assembly and welding of the welded workpiece, but if the fixture quality is not good will cause accuracy errors, thus affecting the accuracy and quality of welding.

3、The situation of the workpiece itself

The same laser welding machine in different workpiece welding work, the quality of welding may also be different. Because the precision of the laser welding machine also has a certain limit, and if the welding workpiece for the precision requirements are too high, the welding process may have certain defects, and if the surface of the workpiece itself is not clean, or the uniformity of the workpiece is not good, which will also affect the aesthetics of the weld, thus affecting the effect of the welding presented.

These are the factors that affect the quality of laser welding equipment, after a better analysis of these factors, the majority of friends can better grasp the impact of various factors on hand held fiber laser welder. To achieve high efficiency, high quality welding effect.