China handheld fiber laser welding machine 2022 in the market above the more hot, the reason is that handheld laser welding machine is to save labor, fast, high efficiency, low cost advantages.

Handheld laser welding machine is simple to operate, the main advantage is that female workers can operate, so it is relatively convenient for enterprises, recruiting simple at the same time can also be the seam welding more perfect, so handheld laser welding machine has become the darling of the times.

Handheld laser welding machine applications.

Handheld laser welding machine welding seam firm, easy to operate, fast welding speed, no consumables, thin stainless steel plate, iron plate, galvanised plate and other metal materials welding, cabinet kitchen, shelves, ovens, stainless steel doors and windows, electrical boxes, stainless steel home and other welding processing.

The welding seam is flat and firm, fast, the welding heat affected area is small, it will not lead to deformation of the workpiece, blackening, back traces and other problems, the welding depth is large, the melting is sufficient, it can be welded ultra-thin, almost no need to grind and polish.

Handheld laser welding machine features.

The handheld fibre optic transmission laser welding machine is flexible, convenient and has a long welding distance, overcoming the limitations of the workbench and the inability to automatically weld when the size of the workpiece is not uniform, and can be used for large workpieces, fixed positions, outside right angles and flat welding seams.

Small heat affected area, small deformation, large welding depth and solid weld seam. Equipped with fibre optic pulse or continuous type welding, the whole machine is maintenance free, the light spot is small, suitable for high precision parts welding. Equipment production, fast welding speed, reduce production costs and improve workpiece quality.

Suitable for welding thin plates with stable welding quality without deformation, automated mass production, improved production efficiency and yield rate, high production efficiency.

Performance features of the handheld laser welding machine for stainless steel

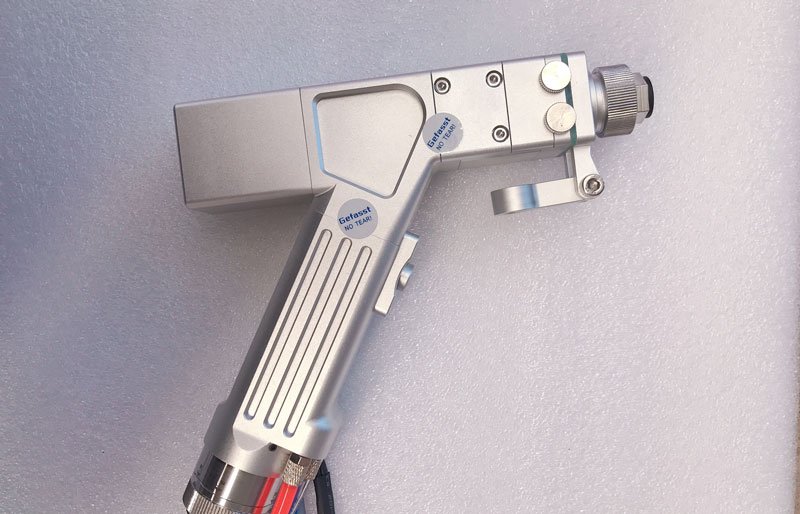

Newly developed welding head safety induction function, the welding head contact with the metal before being able to send out the laser.

Newly developed spiral jitter function, the width of the welding seam is adjustable, no longer afraid of the gap is too large, welding capacity, greatly enhanced.

The new design and material of the welding head, the precise and easy positioning of the tip, the smooth sliding of the wire, the resistance to spatter and high temperatures, the life span of several years, and the possibility of changing to different models.

The lighter design of the tip, at 600-800g, is close to the weight of a bottle of peasant water, making it easier to operate for long periods of time. No technical barriers, no programming or instruction required, just weld with your hands, even for novices.

The welding seam is exquisite, the weld is fast and the welding speed is 3-10 times faster than traditional argon arc welding and plasma welding.

Low thermal distortion, can weld ultra-thin materials (below 0.1mm thickness) with almost no grinding and polishing.

How to tread lightning low with a handheld laser welder

Now many companies selling laser welding machines support free samples, so when you want to buy a handheld laser welding machine first take your sample to let the company help you with a sample to see if you are suitable for the right handheld laser welding machine, after the sample and then choose to buy. Aluminum welding machine laser is the core part of the handheld laser welding machine, a good laser can avoid future failures and improve the efficiency of the stainless steel laser welding machine.

Since the seam welding, so the later handheld laser welding machine technical team is more important, 1000w handheld laser welding machine in the later use of welding problems, auxiliary gas, optical path, perforation and other problems can help solve in a timely manner, so that the technical team is what you need later, rather than a low price to buy no follow-up after-sales service.

The handheld laser welder has a smaller footprint and is more flexible and convenient

One-piece design, laser, water tank, control part integrated together, smaller footprint, low site requirements, equipped with mobile pulley, can be adjusted to the site requirements at any time, convenient and flexible.

The hand-held welding torch, with optional 3m, 5m and 8m transmission fibres, breaks through the limitations of the workbench and enables a wider welding range, suitable for all kinds of complex welds and can weld any part of the workpiece and at any angle.

Handheld Fiber Laser Welding Machine for Sale parameters

| Laser power | 1000w 1500w 2000w available |

| Laser type | Continuous fibre laser |

| Laser life | approx. 100,000 hours |

| Fibre length (working radius) | 8-10 m, different lengths can be customised |

| Welding depth | Sheet metal, butt welding: 0.1-3mm; lap penetration welding: 0.05-5mm |

| Weld seam width | Single track weld <2mm, swing head weld >5mm |

| Straight line welding speed | 200mm/S (depending on material) |

| Power range | 10% – 99% |

| Power consumption | approx. 1000-5000 watts (full power out of light) |

| Servo power | approx. 100 watts |

| Weight | 300-1500 watts approx. 200 kg, 2000 watts approx. 300 kg |

| Power supply requirements | Two-phase 220V/50HZ and three-phase 380V/50HZ available |

| Operating temperature | 0-40°C |

| Operating Humidity | 20%~90% |

| Equipment size | L X W X H: 1150X1150X600mm (dimensions may change with product updates and customisation) |

china handheld laser welding machine manufacturers low cost of use and maintenance

Continuous laser electro-optical conversion efficiency of more than 30%, 10 times higher than that of solid-state YAG lasers (3%), with power stability of ±0.5%.

No optics in the resonant cavity, the pump source has a lifetime of greater than 100,000 hours and is essentially maintenance free.

No need to add welding wire during welding, no additional consumables costs.

Three solutions for low temperature protection of lasers.

In winter, when the temperature is quite low, we often encounter laser welding machine water machine can not be turned on the situation. Today china handheld fibre laser welding machine suppliers explain how you should respond.

In winter, when the temperature is quite low, we often encounter laser welding machine water machine can not be turned on the situation. Today china handheld fibre laser welding machine suppliers explain how you should respond.

Normal water machine temperature set at 27-28 degrees range, the water machine because of the weather will appear low-temperature alarm, the correct approach is to first turn on the water machine, let the water machine energized for a period of time, or you can use the heater properly plus the appropriate amount of boiled water, so that the machine warms up rather faster, or the water machine placed in the place temperature must be maintained at 12 degrees or more.

Keep the water cooler from shutting down

In the event of a local power failure that will not occur, the water chiller can be kept running while setting both the low temperature water and the room temperature water to around 5°C to ensure that the cooling water is above the freezing point while saving power.

Emptying the cooling water from the machine

Empty the cooling water from the laser and chiller after each use.

Replace the cooling water with antifreeze

Antifreeze must be used when there are frequent power outages and when it is not possible to drain the cooling water every day.

Antifreeze is corrosive and when adding antifreeze to the water tank of a chiller, the following matters need to be noted.

1, the antifreeze and water in a certain proportion of exchange after adding.

2, the use of low concentration of antifreeze.

3, antifreeze is not easy to mix, please use the same brand of the same type of antifreeze.

4、Antifreeze should not be used for a long time. When the temperature warms up, the antifreeze should be replaced by pure water.

Antifreeze selection

Please choose antifreeze with the right freezing point according to the local temperature. The choice of antifreeze is not based on the lower the freezing point, but rather on the lowest local temperature, which is slightly lower than the local temperature.

We recommend using a professional brand of antifreeze to add. Note: Any antifreeze is not a complete substitute for deionised water and is not recommended for prolonged use throughout the year. After the winter has passed it is recommended to use deionised or distilled water to clean the pipes and return to using deionised or distilled water as a coolant.

If there is a long shutdown (e.g. during the Chinese New Year shutdown), it is recommended to empty the cooling water from the equipment and to use compressed air to blow the residual water from the equipment, including the laser and chiller, clean.

Notes on laser welding machine chillers water machines.

Water machine is strictly prohibited without water on, water machine is strictly prohibited to signal line short state, the machine must be placed in a dry, ventilated, and can not be subjected to direct sunlight, one water machine cooling wind dispersion of the air outlet can not be blocked, the front of the place within 1 m can not have obstacles, water pipes can not be folded to ensure ventilation and cooling and water flow smoothly

The working principle of fibre laser welding machines and YAG laser welding machines

Laser welding machine is a kind of machine applied in the field of welding, is one of the important aspects of the application of laser material processing technology, according to its working method can be divided into laser mould and welding machine, automatic laser welding machine, laser spot welding machine, fiber laser welding machine, etc., here for china handheld laser welding machine manufacturer for everyone to introduce in detail。

How handheld fiber laser welding machines work

When pump light passes through a rare earth ion in an optical fibre, it is absorbed by the rare earth ion. At this point the rare earth atomic electrons that absorb the photon energy are excited to a higher excitation energy level, resulting in an inversion of the ion number, which is then transferred from the high energy level to the ground state in the form of radiation and releases energy to complete the excited radiation. The laser produced by the fibre laser welding machine is output through the fibre optic and works in conjunction with the matching table to complete the corresponding welding. Fiber laser welding machines are divided into pulsed fiber laser welding machines and continuous fiber laser welding machines. The pulsed fibre laser welding machine can be adjusted by setting the peak laser power, frequency and pulse width to adjust the laser pulse single point energy; the continuous fibre laser welding machine is set by the average laser power to adjust the output laser power.

How YAG laser welding machines work

he laser power supply first lights the pulse xenon lamp, through the laser power supply to the xenon lamp pulse discharge, forming a certain frequency, a certain pulse width of the light wave, the light wave through the concentration cavity radiation to the Nd 3+: YAG laser crystal, excite the Nd 3+: YAG laser crystal light, and then after the laser resonance cavity resonance, issued a wavelength of 1064nm pulse laser, the pulse laser after beam expansion, reflection, (or by The pulsed laser is focused on the object to be welded after beam expansion, reflection, (or by fibre optic transmission); under the control of a PLC or industrial PC, the CNC table is moved to complete the welding.

The frequency, pulse width, waveform, table speed and direction of movement of the pulsed laser required for welding can be controlled by a microcontroller, PLC or industrial PC, and the energy of the pulsed laser can be adjusted by different settings of the laser frequency and pulse width.

china handheld laser welding machine for sale

china handheld laser welding machine Videos

The above is china handheld laser welding machine manufacturers about 1000w/1500w handheld laser welding machine some information, if you are interested in our handheld laser welding machine, you can consult WhatsApp: 86-18654506392