The rapid development of the industrial market, handheld laser welding machine in the advertising industry, agricultural machinery manufacturing, machinery production, aircraft and ship production and other industries are widely used, aluminum alloy laser welding machine is relatively widely used some. Now China laser welding machine manufacturers to introduce you to the information about the aluminum laser welding machine.

Do you want to buy laser welding machine for aluminum plans or want to buy affordable handheld aluminum laser welder in China for advertising signage, tire cleaning, kitchenware, automotive, aerospace, electronics manufacturing and other industries with products widely available for cleaning in USA, Canada, Australia, UK, Russia, South Africa, India and other Asian countries.

What is an aluminum laser welding machine

Aluminum and aluminum alloys have very good properties, such as high specific strength, corrosion resistance, in many industries have a very wide range of applications, especially in the defense industry, machinery and other industries, and aluminum alloys are non-ferrous metals, in the process of application requires welding, so with the rapid development of science and technology, the welding technology of aluminum alloy research is becoming more and more in-depth. Therefore, laser welding technology is a great progress of science and technology.

How laser welding machine works

Laser welding as a new welding technology, welding heat source is directly laser, can avoid the waste of energy, but also can greatly improve the efficiency of welding.

Laser welding uses robots or CNC machines as the movement system, reducing the involvement of personnel, which can reduce the waste of labor and improve the efficiency of welding.

In addition to the advantages of being renewable and clean and pollution-free, laser heat sources can be highly focused and have good performance in transmission, so that the energy can all converge and concentrate on one point, avoiding heat dissipation and waste. Therefore, laser welding can improve the efficiency and speed of welding as well as the quality of welding.

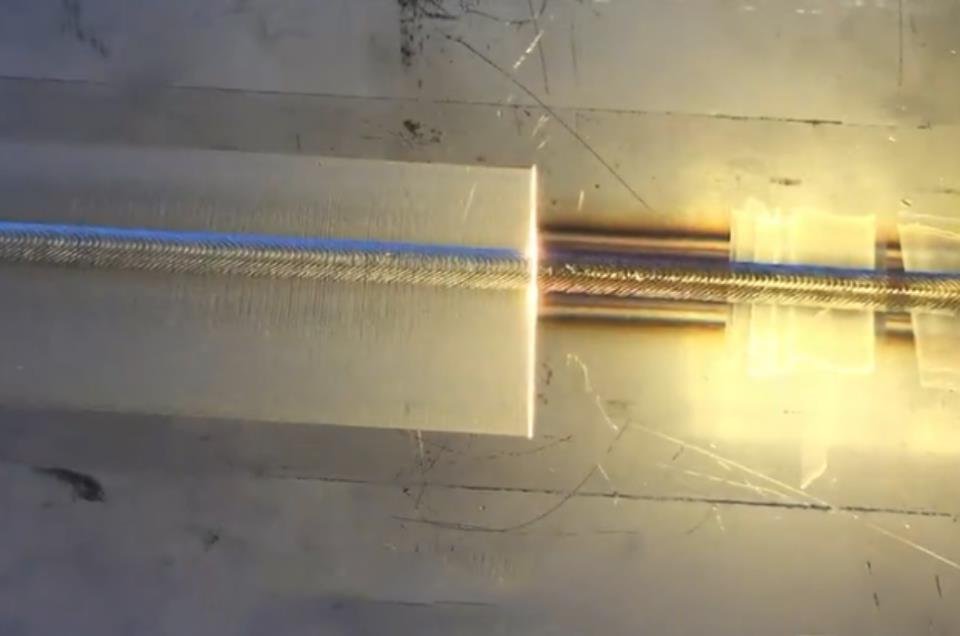

Because the laser welding beam is realized by pulsed or continuous laser beam, when the laser beam directly irradiates the surface of the aluminum alloy, it can spread the heat from the metal surface to the inside of the aluminum alloy rapidly, causing the aluminum alloy to melt rapidly to form a weld seam, and at the same time, a reaction force is formed on the melted metal, which eventually depresses the surface of the melted aluminum alloy downward to form a small hole. This small hole has a powerful effect, can all absorb the energy generated by the laser beam irradiation, and at the same time generate high temperature steam, steam pressure and wall surface tension to form a dynamic balance.

Power of industrial laser welding machine

The current power of industrial laser welding machine are: 1000w handheld fiber laser welding machine ,1500w handheld laser welding machine,2000w laser welding machine ,lightweld 1500 laser welding system,ipg lightweld 1500 for sale

Speed of laser welding machine

Because of the high power of laser welding, the speed of welding is also increased accordingly. The increasing speed of welding can make the depth of melt decrease continuously, on the contrary, if the speed is slowed down, the aluminum alloy will be over-welded or even welded through.

Fiber metal laser welding machine in various fields of application

Application in the oil pipeline

In the oil pipeline, the application of aluminum alloy pipeline can increase the caliber of the pipeline, thicken the wall of the oil pipeline, so that the pipeline can transport more oil in a certain period of time. The transportation of oil has a very high risk, such as oil leakage, will cause incalculable property damage, casualties and environmental pollution and groundwater pollution, so aluminum alloy pipeline in the welding must pay special attention to improve the quality of welding, laser welding can play a huge role at this time, through laser welding, you can control the process of conforming to the welding, you can do without opening the bevel The welding operation, welding once formed, the quality of the weld is high, fully avoid the risk of oil leakage, improve the safety of oil transportation.

Application in the automobile manufacturing industry

With the rapid development of the times and people’s living standards increasingly high-speed, out of the car has become commonplace, and people’s requirements for the quality of cars are increasingly high, so the automotive industry is constantly looking for new materials and technical means to improve the quality of cars, laser welding technology in the automotive industry has become more and more widely used.

The United States was the first to introduce laser welding aluminum alloy technology into the automotive manufacturing industry, after a series of experiments, laser welding aluminum alloy manufacturing out of the car, the thin aluminum alloy after laser welding manufacturing molding, not only greatly reduce the weight of the body, but also reduce the manufacturing process of the car, improve the production efficiency, the majority of the automotive manufacturing industry welcomed and favored.

Application in the aerospace industry

As we all know, the aerospace industry requires highly accurate and precise materials for the manufacture of aircraft and a series of spacecraft, and for the weight of the machine itself is also very strict requirements, the use of laser-welded aluminum alloy manufacturing aircraft and other machines, can make the body than usual can be reduced by about 20%, manufacturing costs have also been greatly reduced.

For example, the A350 series of aircraft parts produced by the German condominium production plant using laser-welded aluminum alloy technology have been a great success.

Difficulties of industrial laser welding aluminum technology

Aluminum alloy surface is reflective to laser light

Because aluminum alloy is a non-ferrous metal, it has strong reflectivity to all kinds of light, and laser as a more intense beam, it is more likely to cause reflection on the surface of aluminum alloy, in other words, aluminum alloy is a non-ferrous metal for laser has high reflectivity and small absorption rate. Besides, all metals have thermal conductivity, so aluminum alloy also has strong thermal conductivity, which can easily reflect the laser or move the laser heat out quickly when welding with laser, and eventually lead to the failure of aluminum alloy welding.

Therefore, when industrial laser welding aluminum alloy, pay strict attention to and quickly increase the power density of the laser to prevent being reflected or conducted, and strive to weld the aluminum alloy at extreme times with very high density, so that problems such as reflectivity can be avoided.

Be well prepared for laser welding of aluminum alloys

Because the aluminum alloy is active and easily oxidized, a lot of dust and water are easily attached to its surface. Therefore, if sufficient preparation is not made during the welding process, the things attached to the surface will easily stay on the surface of the aluminum alloy with the rapid welding of the laser, thus affecting the quality of the aluminum alloy and the welding effect. Therefore, before welding the aluminum alloy, it is necessary to clean the surface of the aluminum alloy and clean off the oil and dirt on the surface. At the same time to prevent the occurrence of oxidation during welding caused by explosions and other safety threats, but also need to thoroughly clean the metal surface of the oxide film, completely remove the oxide film.

Defects of laser welding of aluminum alloys

Defects of laser welding of aluminum alloys

Although laser welding has high efficiency, high speed and can significantly reduce costs, laser welding also has many shortcomings, only these defects are clear and solved, to make laser welding of aluminum alloy technology to be more widely used.

The defects of porosity

In the above mentioned, moderate porosity can maintain the internal and external balance of the aluminum alloy, but excessive air bubbles will be a large number of defects, to avoid a large number of porosity is more difficult, a large number of porosity when the porosity is unstable, in the aluminum alloy internal scurry, easy to make the welded parts of the cracks, so the removal of porosity will be a major defect in the aluminum alloy laser welding technology needs to break through.

Thermal cracking defects

Application of laser technology, the need to increase the temperature and density to achieve the purpose of rapid welding, which is easy to appear in the aluminum surface of the special crack, thus making the welding failure, in order to deal with thermal cracking, scientists have come up with ways to deal with the use of filler material in laser welding, but this method is likely to lead to a waste of resources and a lot of labor costs. A more simple way to deal with thermal cracking is also a major problem that will be solved by the technology.

There are a large number of advantages of laser welding speed of aluminum alloy, which has been widely used in a variety of manufacturing fields and has also improved the quality and manufacturing speed of the machine itself, but handheld laser welding technology also has many defects that lead to welding failure, I believe that under the continuous efforts of scientists, the welding technology will become more and more mature and more widely used.

If you want to know more information about fiber laser welding machine for aluminum, you can follow us or contact whatsapp:86-18654506392