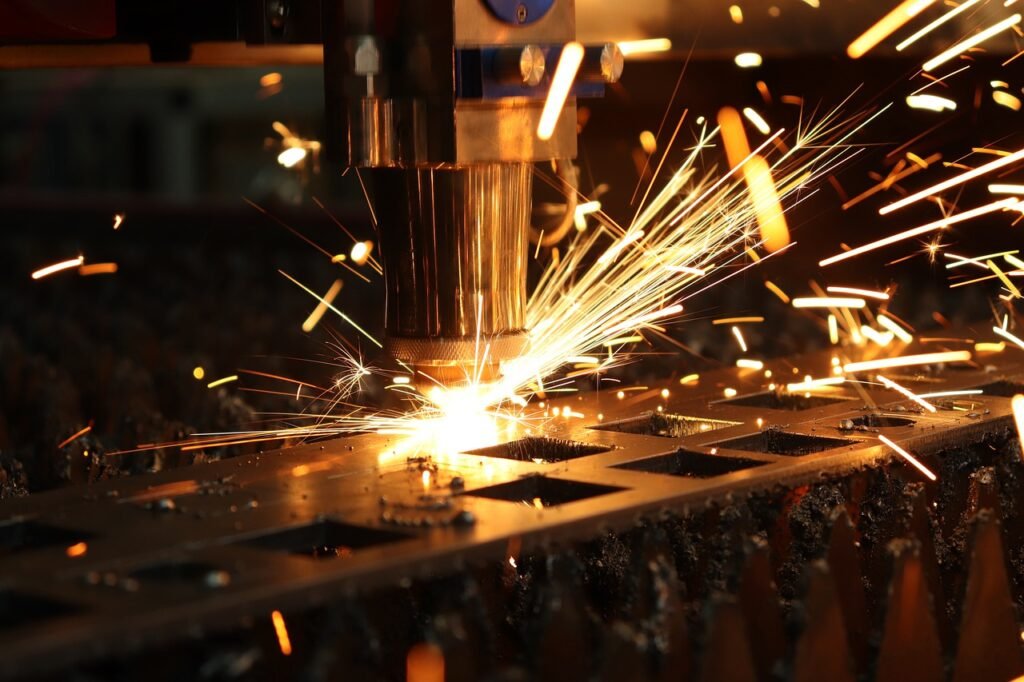

After purchasing the fiber laser cutting machine, the customer knows very little about the protection knowledge of machinery. Now let’s learn about the protection knowledge of the fiber metal laser cutting machine.

Necessary protective equipment for laser cutting machines.

The typical protective equipment for laser cutting machines is laser protective goggles, because protective goggles to prevent laser damage to human eyes can be divided into reflective, absorbing, diffractive and composite types according to their protection principles. Of course, they It will be filtered and protected according to the laser radiation wavelength of the laser cutting machine, so as to protect the laser of the laser cutting machine of the human body.

Self-protection of laser cutting machine radiation.

If the human body has enough health, it can resist a little radiation from the laser cutting machine. Therefore, laser cutting machine operators should pay attention to eating more carrots, bean sprouts, tomatoes, lean meat, animal livers and other foods rich in vitamins A, C and protein, as appropriate, and often drink green tea and so on. Because these foods can help humans better protect their eyes, so that the human body can better protect the human body under the condition of laser cutting machine radiation.

How to use CNC fiber laser cutting machine?

Now many customers who have purchased fiber laser cutting machines have always had a question about how to use them. Now let me tell you the precautions in the use of fiber laser cutting machines:

- Follow general cutting machine safety procedures. Start the laser strictly according to the laser start-up procedure.

- The operator must be trained, familiar with the structure and performance of the equipment, and master the relevant knowledge of the operating system.

- Wear labor protection equipment according to regulations, and wear protective glasses that meet the regulations near the laser beam.

- Do not process a material without knowing whether it can be irradiated or heated with a laser to avoid the potential danger of fumes and gases.

- When the equipment is started, the operator shall not leave the post without authorization or trust someone to be in charge. If it is really necessary to leave, the operator should stop or cut off the power switch.

- Keep fire extinguishers within easy reach; turn off lasers or shutters when not working; do not place paper, cloth, or other flammable objects near unprotected laser beams.

6 major cleaning of metal laser cutting machine

1: Water replacement and water tank cleaning

Recommendation: Clean the water tank and replace the circulating water once a week.

Note: Make sure that the laser tube is full of circulating water before the machine works.

The quality and temperature of the circulating water directly affect the service life of the laser tube. It is recommended to use pure water and control the water temperature below 35°C. If it exceeds 35°C, the circulating water needs to be replaced. (It is recommended that the user choose a cooler, or use two water tanks).

Cleaning the water tank: first turn off the power, unplug the water inlet pipe, let the water in the laser tube automatically flow into the water tank, open the water tank, take out the water pump, and remove the dirt on the water pump. Clean the water tank, replace the circulating water, restore the water pump to the water tank, insert the water pipe connecting the water pump into the water inlet, and arrange the joints. Power on the water pump alone and run it for 2-3 minutes (to fill the laser tube with circulating water).

If the temperature in the northern region is very low in winter, it may cause the water in the laser tube to freeze. You can properly add antifreeze to prevent the water from freezing and cause the laser tube to rupture.

2:Fan cleaning

The long-term use of the fan will cause a lot of solid dust to accumulate in the fan, which will make the fan generate a lot of noise, and is not conducive to exhaust and deodorization. When the suction of the fan is insufficient and the smoke exhaust is not smooth, first turn off the power, remove the air inlet and outlet ducts on the fan, remove the dust inside, then turn the fan upside down, and pull the fan blades inside until it is clean. , and then install the fan.

3: Cleaning of the lens

(It is recommended to clean before work every day, and the equipment must be turned off)

There are 3 mirrors and 1 focusing mirror on the engraving machine (the No. 1 mirror is located at the emission exit of the laser tube, which is the upper left corner of the machine, the No. 2 mirror is located at the left end of the beam, and the No. 3 mirror is located at the fixed part of the laser head. The top of the laser head, the focusing mirror is located in the adjustable lens barrel at the lower part of the laser head), and the laser is reflected and focused through these mirrors and emitted from the laser head.

The lens is easily stained with dust or other contaminants, causing laser wear or damage to the lens. No. 1 and No. 2 lenses do not need to be removed when cleaning, just carefully wipe the lens paper with cleaning fluid from the center of the lens to the edge. Rotary wipe.

The No. 3 lens and the focusing lens need to be taken out of the frame, wiped in the same way, and then put back as they are after wiping.

Notice:

- The lens should be wiped gently without damaging the surface coating;

- The wiping process should be handled with care to prevent falling;

- Please keep the concave side down when installing the focusing lens.

4:Cleaning of guide rails

(It is recommended to clean it once every half a month, and shut down the machine.) As one of the core components of the equipment, the guide rail and the linear axis play a guiding and supporting role.

5:Observe whether there is abnormal noise or abnormal phenomenon in the transmission parts

After the tightening motion system of the screws and couplings has been working for a period of time, the screws and couplings at the moving joints will become loose, which will affect the stability of the mechanical movement.

Therefore, it is necessary to observe whether there is any abnormal noise in the transmission parts during the operation of the machine. Or abnormal phenomenon, found the problem should be strengthened and maintained in time. At the same time, the machine should tighten the screws one by one with a tool over a period of time. The first firming should be about a month after the device is used.

6:Inspection of the optical path

The optical path system of the laser cutting machine is completed by the reflection of the mirror and the focusing of the focusing mirror. There is no offset problem of the focusing mirror in the optical path, but the three mirrors are fixed by the mechanical part, and the possibility of offset is relatively high. Large, although there is usually no offset, it is recommended that the user must check whether the optical path is normal before each work.

The editor will push articles about fiber metal laser cutting machines from time to time, please pay attention to the follow-up articles, I hope it will be helpful to everyone.