Many customers consult us how to choose a Chinese sheet metal laser cutting machine, I don’t know how to choose. Now let Sheet Metal Laser Cutting Machine China tell everyone 5 methods.

Laser cutting technology occupies a large market share in the sheet metal processing industry. There are many large and small manufacturers on the market to produce different performance and different quality laser cutting machines, which has led many customers to do not know how to choose sheet metal laser cutting machines. The following introduces how to correctly select the sheet metal laser cutting machine.

Choose the right Chinese sheet metal laser cutting machine manufacturer

Scope of business needs

First, we should clearly consider the scope of our business. The thickness of the material to be cut, which materials need to be cut and some other process factors, then determine the equipment power and console size that need to be purchased. At present, the power of sheet metal laser cutting machines on the market ranges from 3000w to 30000w, and the size of the operating table is generally 3015~12025 (processing length 3m* total width 1.5m; processing length 12m* total processing width 2.5m), special size manufacturers Can be customized according to customer needs.

Preliminary selection of manufacturers

After determining the demand, we can go to the market to understand or have purchased the sheet metal laser cutting machine from the peers, and examine the performance and basic parameters of the machine. Select several powerful and large-scale manufacturers for investigation, research and proofing. Specifically, it includes details such as production scale, delivery cycle, transaction method, delivery instructions, training method, and after-sales matters.

The size of the laser power

When choosing the performance of a sheet metal laser cutting machine, you should fully consider your own environment. The size of the laser power is very important. Different power sizes can be cut with different thicknesses. For thin plates, you can choose a lower power, and for thick plates, you need to choose a higher power. For the specific power selection, you can consult a technician according to your own processing thickness requirements.

Choose important accessories

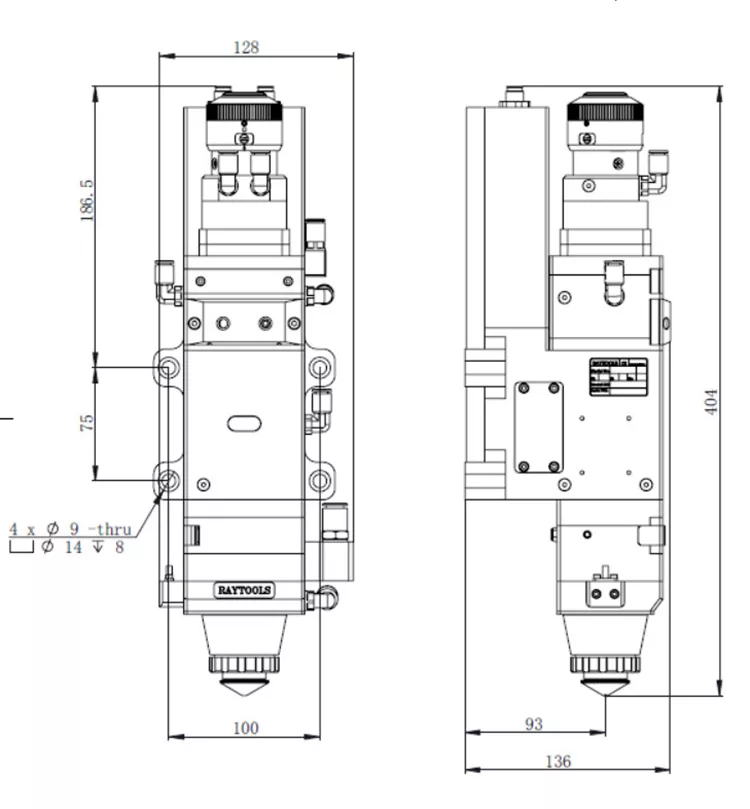

When purchasing a sheet metal laser cutting machine, some important accessories require great attention. Especially for lasers, cutting heads, servo motors, slide rails, water tanks, etc., it is necessary to clearly distinguish whether they are domestic or imported brands. These parts directly affect the cutting speed and accuracy of the sheet metal laser cutting machine, and the prices of different brands are also very different. Many domestic informal manufacturers will use domestic as imported accessories to deceive customers.

After-sales service

No matter how good a sheet metal laser cutting machine is, users will encounter some problems during use. When encountering problems that cannot be solved, it is very important for manufacturers to provide timely solutions, which is also an important factor that we need to consider when purchasing a sheet metal laser cutting machine.

Can a sheet metal laser cutting machine cut aluminium sheet?

Laser cutting machine according to the laser generator can be divided into different types, different types of equipment for different cutting materials have their own specialties, aluminum as a high anti difficult to cut metal materials, from the point of view of cost and input, we used to commonly used to fiber laser cutting machine and YAG laser cutting machine is the main.

Today we have these two types of equipment to give you a comparative analysis of aluminum cutting.

The comparison of aluminium laser cutting machine from three points to consider: cutting quality, cutting speed and production costs (refers to the cost of life).

Cutting quality

Aluminium is a highly reflective material, and therefore either fiber laser cutting machine or YAG laser cutting machine can not be processed thicker aluminum, in addition to the aluminum material is not resistant to high temperatures, cutting aluminum process is prone to burrs, so you need to focus on controlling the process, to get the ideal cutting quality.

Cutting speed

Cutting speed also needs to be controlled, too fast cutting speed is prone to burrs, too slow cutting speed will make the aluminum material cracks, all affecting the quality of cutting, and thus the need for process control, in general, the same power of laser cutting equipment, fiber laser cutting machine cutting speed is higher than the speed of YAG laser cutting machine.

Production costs

Sheet metal laser cutting machine processing costs are very low, far below other cutting processes, fiber laser cutting machine and YAG laser cutting machine as a comparative view, fiber laser cutting costs are lower than YAG laser cutting machine, the latter requires frequent replacement of laser lamps and other accessories, but from a long-term perspective, aluminum material on the fiber laser cutting machine laser damage is more serious, greatly reducing the laser life, which at this point in time YAG to be lower than the cost of fiber laser cutting machine.

From the above three points of analysis, we can see that in the cutting of aluminum, the performance of these two types of laser cutting machines have their own advantages and shortcomings, in addition, it should be noted that aluminum has high reflectivity, low absorption of laser light, so the processing process requires the wearing of laser protective glasses to protect their own safety.