China Fiber Laser Cutter Manufacturers

Provide you with a one-stop metal cutting solution

We only select the best and most affordable sheet metal laser cutting machine equipment for you.

Professional and technical personnel conduct technical training 1 to 1 and serve you 7*24 hours!

What is the composition of a metal laser cutter?

Metal laser cutting machines consist of laser generators, cutting heads, beam transmission components, machine tables, CNC systems and cooling systems.

Product By Features

1530 Most Affordable CNC Desktop Laser Cutter Price For Sale

Power: 1000w/1500w/2000w/3000w optional

Sheet thickness: stainless steel 1-12mm Carbon steel 1-16mm

Use: stainless steel sheet cutting

Application areas: advertising signs, kitchen cabinets, sheet metal processing

3kw 4kw 6kw Industrial Desktop Fiber Metal Laser Cutter Price For Sale

Power: 3000w/4000w/6000w optional

Countertop: 3015/4015/4020/4025/6015

Purpose: Thick plate cutting

Application areas: machinery manufacturing, agricultural machinery, aircraft manufacturing, ship manufacturing

Stainless Steel, Brass, Aluminum Plate Cnc Metal Precision Laser Cutter For Sale

Power: 1000w/1500w/2000w/3000w optional

Countertop: 1530/4015/4020/4025/6015

Purpose: Thin plate cutting

Application areas: fitness equipment, environmental protection industry, pipeline processing, water purification equipmentn

1000w 1500w 2000w 3000w china stainless steel And tube plate laser cutting machine factory For Sale

Power: 1000w/1500w/2000w/3000w/6000w optional

Countertop: 3015/4015/4020/4025/6015

Purpose: Thick plate cutting

Application areas: fitness equipment, environmental protection industry, pipeline processing, water purification equipment

3000w 12000w 6kw cnc exchange table fiber laser cutter manufacturers prices in china For Sale

Power: 3000w/6000w /12000w optional

Countertop: 4020/4025/6015/8025/12025

steel thickness:12mm-40mm

Application areas: machinery manufacturing, agricultural machinery, aircraft manufacturing, ship manufacturing

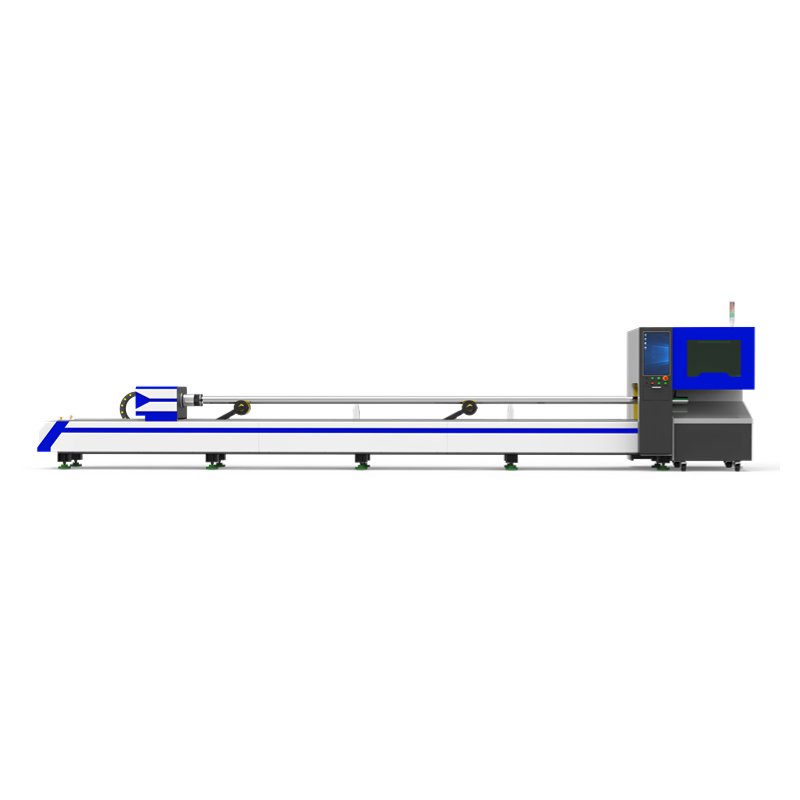

The Cheapest Metal Laser Tube Cutting Machine Price For Sale

Power: 1000w/1500w/2000w/3000w optional

Countertop: 6016/9016

Uses: metal pipes, square pipes, round pipes, special-shaped pipes, channel steel, I-beam

Application areas: fitness equipment, kitchen utensils, machinery production, elevators, automobile industry

Fiber Laser Cutting Machine Cutting Effect

China steel sheet laser cutting machine manufacturers,we only select the best and most affordable sheet metal laser cutting machine equipment for you. Professional and technical personnel conduct technical training 1 to 1 and serve you 7*24 hours!

china stainless steel laser cutting machine

Low-power laser cutting machine mainly cuts thin plates, suitable for advertising industry, sheet metal shell

Laser Cutter Cutting Carbon Steel

3kw-6kw laser cutting machine mainly cuts carbon steel plate, suitable for machinery, elevator industry, automobile manufacturing, etc.

Carbon Steel Plate

8kw-20kw High power laser cutter can cut 40-50mm,Suitable for industries such as large equipment and ship manufacturing

Pipe Cutting Effect

Square pipe, round pipe, special-shaped pipe, angle steel, channel steel can be cut.Tube laser cutting equipment is suitable for elevator industry, ship industry, fitness equipment, etc.

Don't just focus Sheet Metal Laser Cutter Price

The installer is composing the laser cutting machine

Workers are installing laser cutting machine lines

The assembler carefully assembles the fiber laser cutting machine equipment

Why choose our laser cutting equipment

Factory direct sales

12 years of manufacturing experience

Competitive Price

Get a more affordable laser cutting machine to reduce costs.

Professional technical team

Professional 1 to 1 technical support

The laser cutting machine has good cutting quality and reduces labor costs

The laser cutting machine uses the characteristics of laser non-contact processing, does not damage the workpiece, the cut product has no extrusion deformation, the processed product is of good quality, has no burrs, does not require manual re-grinding, saves unnecessary processing procedures, and optimizes worker labor. strength.

Metal laser cutting machine saves mold investment and reduces production costs

The metal laser cutting machine can directly make various hardware workpieces without molds, without mold consumption, without the need to repair and replace molds, which can save the use of a large number of molds, save processing costs, and reduce production costs, especially for the processing of large products.

Plate laser cutting machine has high precision and effectively improves productivity

The cutting process of sheet metal laser cutting machine appears as an alternative process of “shear-punch”, which has the characteristics of precision, flexibility and high efficiency, and can effectively process various complex parts. You can set the size for cutting, which helps to directly shorten the product processing and manufacturing cycle, and effectively improve labor productivity.

Who Are We?

Provide the most affordable fiber aser cutting machine to meet the needs of industrial production.

Fiber laser cutting machine manufacturer was established in 2008 and has been dedicated to the production and research and development of laser equipment for 13 years. Our professional team is always ready to help you with all your laser equipment needs.

Metal fiber laser cutting machine factory provides one-stop laser equipment solutions at the most cheapest laser cutting machine prices.

Product performance of laser cutting machine

Metal laser cutter has fast cutting speed and optimized working environment

The laser cutting machine cuts quickly, the equipment is stable during operation, the noise is low, there is no dust, and no chemical substances harmful to the human body and the environment are produced. The investment has reduced pollution, helped hardware companies to optimize the working environment, and conform to the trend of environmental protection.

Metal laser cutting machine has low maintenance cost and high cost performance

The maintenance of mechanical products is very expensive, while the laser cutting machine has stable performance, is sturdy and durable, can work continuously, is not easy to be damaged, and has great advantages in terms of later maintenance costs.

Application fields of metal laser cutting machine

Sheet metal processing industry laser cutting machine application

With the rapid development of sheet metal processing technology, traditional sheet metal cutting equipment can no longer meet the requirements of current technology and cutting shape. Laser cutting has gradually replaced traditional equipment with the advantages of high flexibility and fast cutting speed. Fiber laser cutting machine Widespread application in sheet metal processing is an inevitable trend.

Billboard industry use of metal laser cutting machine

Advertising Traditional processing equipment generally uses materials such as processing advertising fonts. Due to the unsatisfactory processing accuracy and cutting surface, the probability of rework is quite large. The high-precision laser cutting technology does not require secondary rework, which greatly improves work efficiency and saves enterprise costs.

Metal Laser Cutting Machine for Kitchen Supplies Use

The traditional processing methods in the kitchenware manufacturing industry are faced with the problems of low work efficiency, large consumption of molds, and high cost of use. The laser cutting machine has fast cutting speed and high precision, improves processing efficiency, realizes customized and personalized product development, solves the troubles of kitchenware manufacturers, and is recognized by kitchenware manufacturers.

Automotive Industry Use of Metal Laser Cutting Machines

There are also many precision parts materials in automobiles, such as automobile brake pads, etc. In order to improve the safety of automobiles, it is necessary to ensure the cutting accuracy. The traditional manual labor is difficult to achieve precision, and secondly, the efficiency is low. The laser cutting machine can be used for faster batch processing, High precision, high efficiency, no burr, with one-shot molding and other advantages

Get A Free Equipment Quotes

Sheet metal laser cutting machine china ,Metal laser cutter machine makes sheet cutting so easy!

1. Turn on the working circuits of each part, including the main power switch, voltage stabilizer, fiber laser power switch, air compressor, air valve, air dryer, etc., to ensure that the power supply system of each part is normal;

2. Trial operation of the machine to confirm that the machine runs smoothly, and the limit and emergency buttons are reliable;

3. Place the material to be cut smoothly on the cutting table of the machine tool, operate the console computer screen at the same time, input parameters such as the thickness of the product material, and import the pattern into the machine;

4. Control the movement of each axis through the functions in the menu, and adjust the cutting position to the appropriate part of the plate;

5. Select the appropriate nozzle and lens, and check to make sure their appearance and cleanliness are in good condition; adjust the cutting head to the appropriate cutting focus position through the direction keys on the panel;

6. According to the cutting requirements, select the suitable cutting gas, and check whether the injection state is good;

7. Start the laser and the machine tool, try to cut the metal raw materials, observe whether the section is smooth and whether the cutting accuracy is accurate. If there is any deviation, adjust the equipment parameters until the proofing meets the requirements; then the equipment automatically starts according to the input parameters and patterns. cutting work;

8. During the cutting process, a staff member must be present. If there is an emergency that requires a quick response, the staff member needs to quickly press the brake button;

9. After completing the cutting work, pay attention to check the cutting accuracy and quality of the product;

Laser cutting machines also play an important role in the medical industry, where extreme precision and tight dimensional tolerances are essential. Due to the medical industry’s need for high volumes, this technology fits their needs as it can replicate designs with both accuracy and quick turnaround. Many types of medical devices have their origins in laser cutting, from cardiovascular and orthopedic devices to surgical implant components. With laser cutting, these devices can be manufactured at relatively high speeds without sacrificing precision.

In the field of automobile manufacturing, the cutting technology of spatial curves such as car roof windows has been widely used. Volkswagen of Germany uses a laser with a power of 500W to cut complex-shaped body sheets and various curved parts. In the aerospace field, laser cutting technology is mainly used for cutting special aviation materials, such as titanium alloys, aluminum alloys, nickel alloys, chromium alloys, stainless steel, beryllium oxide, composite materials, plastics, ceramics and quartz. The aerospace parts processed by laser cutting include engine flame tube, titanium alloy thin-walled casing, aircraft frame, titanium alloy skin, wing truss, tail siding, helicopter main rotor, space shuttle ceramic heat insulation tile, etc.

Laser cutting and forming technology is also widely used in the field of non-metallic materials. It can not only cut materials with high hardness and brittleness, such as silicon nitride, ceramics, quartz, etc., but also can cut flexible materials, such as cloth, paper, plastic board, rubber, etc. % to 12%, increasing the efficacy by more than 3 times.

1. Metal cutting in common application fields of laser cutting

Not only does laser cutting work on a large number of metals, but it is a universal tool among industries. Laser cutting can result in a cleaner, smoother, tighter cut than machining. Like machining, it can also be programmed and directed by a computer, which means that laser cutters can automatically make a large number of metal parts for industries like automobiles, computers, and more. Often, odd shapes like car frames or hydroformed parts require laser cutting, as do many parts in the aerospace industry, and the results are often better than plasma cutting.

2. Reflective metal cutting in common application areas of laser cutting

Because reflective metals reflect the backlight that hits them, this raises concerns when hitting them with high-powered laser beams. If the metal reflects the laser, it will self-destruct. The solution to this problem is fiber laser cutting. With this technique, fiber optic cables transmit the laser beam onto the metal. The reflected light will not damage the fiber optic cable. Metals such as aluminum, silver, copper and gold are all reflective and critical in automotive and semiconductor production.

1. Fast cutting speed: Use a laser cutting machine with a power of 1200W to cut a 2mm thick low carbon steel plate, and the cutting speed can reach 15000px/min; when cutting a 5mm thick polypropylene resin board, the cutting speed can reach 30000px/min. The material does not need to be clamped and fixed during laser cutting, which not only saves tooling and fixtures, but also saves the auxiliary time for loading and unloading.

2. The laser cutting machine adopts non-contact cutting, and the cutting torch has no contact with the workpiece during cutting, so there is no tool wear. When machining parts of different shapes, there is no need to change the “tool”, just change the output parameters of the laser. The laser cutting process has low noise, small vibration and no pollution.

3. High cutting efficiency: Due to the transmission characteristics of the laser, the laser cutting machine is generally equipped with multiple CNC workbenches, and the entire cutting process can be fully CNC controlled. During operation, only by changing the numerical control program, it can be applied to the cutting of parts of different shapes, both two-dimensional cutting and three-dimensional cutting can be realized.

4. Wide range of products that can be cut: There are a wide range of laser cutting materials, including metals, non-metals, metal-based and non-metal-based composite materials, leather, wood and fibers. However, for different materials, due to their own thermophysical properties and different absorption rates of laser light, they show different laser cutting adaptability.

Frequently Asked Questions.

1,If you look at the laser, it can be divided into.

1.solid state lasers. Solid state lasers are divided into ruby lasers, YAG lasers, etc.

2.semiconductor lasers.

3. liquid laser.

4.gas laser.

CO2 laser, of course, which is used for laser cutting YAG and CO2 two.

2, if the structure of the laser cutting machine according to points, can be divided into.

A, desktop laser cutting machine this laser cutting machine is the most common.

Benchtop machines are mainly used for sheet metal processing. Can be used in many industries, such as lift manufacturing, electrical switchgear, grain machinery and other industries based on thin plate processing

B, gantry mounted laser cutting machine

The gantry type laser cutting machine operates with a brushless motor driven laser head, naturally high acceleration and fast moving speed, under the same conditions, it has a faster cutting speed and shorter cutting conversion time.

The gantry type fibre laser cutting machine is characterised by the laser cutting head not moving, the sieve tube is indexed relative to the laser cutting head for the same rotation and moving in the direction of the axis, the advantage is that the overall rigidity of the machine tool is good and the laser output is stable.

Metal laser cutting machine is the laser beam irradiation to the surface of the metal workpiece when the energy released to make the metal workpiece melt and evaporate, in order to achieve the purpose of cutting or engraving, with high precision, fast cutting speed, not limited to cutting pattern restrictions, automatic layout to save material, smooth kerf, low processing costs and so on.

1, Metal laser cutting machine as a relatively best-selling equipment, to buy high-quality products also need to compare three, choose the right cooperation, such as the large family of super energy, focus on metal laser cutting machine research, to provide customized metal laser cutting machine application solutions, a wide range of uses, can be applied to automotive, manufacturing, electrical equipment, hardware kitchenware, ships, electronics, automotive, instruments and other industry sectors.

2, Many customers through are through the online understanding of offline purchase, before buying must choose the factory direct sales, choose this channel to buy not only to protect the quality, the price is also cheaper, reduce the middleman to earn the price difference.

Metal laser cutting machine price is not high, different types, different components of the metal laser cutting machine prices vary, users can not only focus on the price when buying, but also from the actual use of the performance characteristics and advantages of the consideration.

Metal laser cutting machine selection to consider a number of factors, in addition to the current processing of the maximum size of the workpiece, material, the need to cut the maximum thickness and the size of the raw material width, more need to consider the future direction of development.

For example, the size of the largest workpiece to be processed after the technical adaptation of the product to be made, the width of the material provided by the steel market for your product which is the most material efficient, the loading and unloading time, etc. In general, it is recommended that within 25mm carbon steel plate, within 15mm stainless steel plate and other metal materials cutting recommended the use of metal laser cutting machine. Choose this should find a professional metal laser cutting machine manufacturers

Plasma cutting machine cutting surface rough, cutting thick plate has the advantage, and inexpensive, laser cutting cutting surface smooth, plasma is rougher, need to send people to repair the burr of. Laser cutting surface smooth, compensation small precision is higher, a little more expensive.

Cost-wise plasma is cheaper than laser by about 1/3 or so. The most important part of plasma is the power supply, equivalent to the laser cutting machine laser, plasma power consumption is quite strong, commonly used spare parts electrode protection bubble mouth is also quite expensive, especially the electrode drilling is very expensive electrode.

Laser cutting machine and plasma cutting machine detailed distinction between.

1, metal laser cutting machine compared to plasma cutting, laser cutting is much more precise, the heat-affected zone is much smaller, the cut is also much smaller.

2, if you want precision cutting, want a small slit, small heat-affected zone, small plate deformation, it is recommended to choose laser cutting machine.

3, plasma cutting machine is to compressed air as the working gas, high temperature and high speed plasma arc as a heat source, the metal to be cut locally melted, and at the same time with high-speed airflow will have melted metal blown away, the formation of the cut.

4, plasma cutting heat-affected zone is relatively large, the slit is relatively wide, not suitable for cutting thin plates, because the plate will be deformed because of heat.

5, laser cutting machine price than plasma cutting machine to be a little more expensive.

Metal laser cutting machines can be divided by power into low, medium and high power. For thin stainless steel and carbon steel plates, it is possible to use a low-power fiber laser cutting machine can cut well, but also to ensure a higher cutting speed, both to ensure efficiency and cost savings. Therefore, when buying a laser cutting machine, you must choose reasonably according to your material and material thickness, and not blindly pursue high power.

Of course, if you have thick and thin plates, production needs are very large, in its price range of reasonably priced high power laser cutting machine, is also a better choice. Because by properly adjusting the cutting speed, changing the auxiliary gas, etc., the high power laser cutting machine cutting thin plates can also be very good control of the cutting quality.

Choose metal laser cutting machine not to choose ultra-high power nor low power, 3000W metal laser cutting machine can meet most of the industrial production.

Ultra-high power metal laser cutting machine in the price is no advantage, followed by the effect of a large cow pulling a cart, excess performance, low power fiber laser cutting machine it is mainly only adapted to thin plate cutting, a little thicker plate for it, efficiency and slow, cutting effect may not be ideal, affecting economic efficiency and waste of materials.

So 3000W fiber laser cutting machine in the end can cut how thick the plate, the current market above the 3000W fiber laser cutting machine in the case of ensuring the finish and efficiency, you can cut stainless steel 16MM, carbon steel material in about 20MM.

1. Lower power consumption: A typical blanking press or turret punch consumes a total of 50kW of power. A 4kW laser system typically uses 10kW of total power.

2. Safety: Blanking presses have large blades that can move up and down quickly, and do not necessarily have safety features to prevent hands from being pinched. Fiber lasers need to be enclosed in light-tight boxes, which means they are designed to operate without human intervention during the cutting process.

3. Save material waste: Since the cutting tool requires material on either side of the cut, the border needs to be at least 1/2 inch. With lasers, if the parts have the same profile, they can be cut in one cut without scrap. For some materials, the smallest scrap skeletons can also be cut, as small as 1/16 of an inch or less.

4. Cutting performance: The blanking die can only cut materials with maximum tensile strength. Lasers can cut materials of any strength as long as the material can be melted.

5. Low maintenance costs: Blanking presses or turret punches have expensive tools that must be sharpened and stored regularly when cutting different parts. Lasers can change parts by changing the program and require relatively inexpensive replacement parts such as lenses and nozzles.

6. Flexible operation: Traditional blanking lines have a fixed design tool for each part, which is a very high investment, usually costing about $50,000 per tool depending on the shape. The turret hole punch is a bit better because you can program any shape that can be made using the smaller set of shapes, but if you want to change the size of the hole or something like that, the design changes are limited to what is available tools, or new tools must be purchased and the available slots on the turret must be replaced. These tools are less expensive but still require regular maintenance, which is a more specialized task and therefore higher labor costs. The laser can change the cut profile at any time, and it usually takes less than an hour to reprogram, and it costs about $60 to apply the changes, which is an overestimate of the cost.

7. Improved edge quality: Since punching and die-cutting runs through the material, it actually stretches the edge until it breaks, so the top of the part often has rounded edges, while the bottom has a bunch of stretched ribbons that are sharp. Abrasives are sometimes required to remove it, a second step that adds to the price. When properly focused and material is placed, the laser cuts parts with mirror-like edges, the top edge remains square, and the bottom edge is smooth to the touch.

8. Faster changeover: The blanking press takes 30 minutes to change between cutting different parts because the mold has to be changed. Lasers can change programs on the fly, saving time and allowing smaller production runs for lower prices.

A. The fusion cutting method is to irradiate the laser incident light speed into the plate. When the laser power reaches a certain critical value, the local area will be melted, so as to achieve the cutting effect.

B. Vaporization cutting uses high power density laser to heat the processing material to avoid slag burrs formed by melting caused by heat conduction. Some materials evaporate and disappear after evaporation, and the edges are beautiful.

C. Oxidation cutting is a thermal process produced by blowing oxygen in the nozzle and igniting the laser, and the oxygen undergoes a strong chemical reaction; for brittle materials that are easily damaged by heat, laser beam heating can control the cutting at high speed, resulting in a large thermal gradient in this area and mechanical The deformation is severe, causing the material to crack, also known as controlled crack cutting.