China Fiber Laser Cutting Machine Suppliers & Manufacturers

Professional fiber laser cutting machine manufacturer to provide you with one-stop metal cutting solutions

- High precision, high speed and high efficiency

- Serve more than 100 countries and 1000+ customers

- Professional technical team, perfect after-sales service

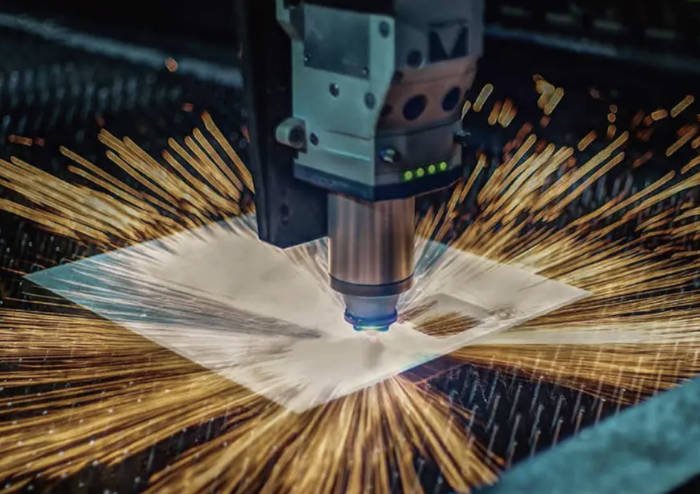

Fiber Laser Cutting Machine Suppliers

Fiber laser cutting machine is a material processing technology that uses a high power density laser to irradiate the material to be cut, so that the material is heated to the temperature of vaporization in a short time, thereby forming a very narrow hole and completing the cutting.

cnc metal fiber laser cutting machine Parameters

- Processing area(L×W): 3000mm×1500mm

- Power: 1000W 1500W 2000W 3000W

- X axis track : 1520mm

- Y axis track: 3020mm

- Z axis track: 150mm

- X,Y axis positioning accuracy: ±0.03mm/m

- X,Y axis repeat positioning accuracy: ±0.02mm/m

- X,Y axis max speed: 100m/min

- X,Y axis max acceleration: 0.8G

- Max.load of worktable: 1000Kg

- CNC system: Bertrude system

- Voltage/power: 380V/50HZ / 10KW

- Dimension(L×W×H): 4200mm×2300mm×1800mm

Cutting product effect display

Application field of fiber laser cutting machine

Why choose our laser cutting machine

Factory direct sales

12 years of manufacturing experience

Competitive Price

Get a more affordable laser cutting machine to reduce costs.

Professional technical team

Professional 1 to 1 technical support

Fiber laser cutting machine with high cutting precision

We can supply all kinds of sheet metal laser cutting machines. Let us know your project specifications and we will provide you with a one-stop solution!

Increased efficiency and cost savings

Good flexibility, new product development without re-moulding, greatly shorten the development time of new products and reduce the cost of development.

High precision and speed

High-speed, high-quality laser cutting of carbon steel, stainless steel, copper, aluminium and other metal materials.

What we can offer you fiber laser cutting machine distributor

Do you need help with your business prototyping? KDM can be your reliable partner. We manufacture and develop cnc fiber laser cutting machines to help you launch your products successfully.

We have extensive competence in the manufacture, production and development of cnc fiber laser cutting machines.

Our team consists of experienced project engineers who will work with you. We also have friendly customer service staff that will help you understand your fiber laser cutting machine production needs. They will customise a different fibre laser machine to your requirements

If you need fiber laser cutting machine factory, we are here to support you. Contact us today!

China Fiber Laser Cutting Machine Factory

We can offer you the best and most affordable price for cnc fiber laser cutting machine, and if you need sheet metal prototyping, we’ve got your back. Contact us today!

Related Products

Collection of Fiber Laser Cutting machine Questions

3015 CNC desktop fiber laser metal cutting machine configuration.

1, The bed is strictly heat-treated.

2, The main machine all adopt Japan Yaskawa motor, a total of 4 servo motors.

3, Interactive cutting table, fast exchange speed, higher cutting efficiency.

4, The whole bed above 4mm screw holes are all planed and milled by COLGAR large milling machine.

5, The whole machine adopts electric timing oil pot, which can reduce the loss of equipment caused by the lack of lubrication.

Components of fiber laser cutting machine

The laser cutting machine is mainly composed of laser generator, cooling water circulation device, air compressor, transformer, numerical control system, operating table, cutting head and host.

Laser cutting machine is a laser cutting equipment used to cut and process metal materials. When working, laser cutting machines have the characteristics of fast cutting speed and high cutting accuracy, so they are also widely used in different industries. So, what parts does a laser cutting machine consist of?

1. Host: The bed, beam, worktable, Z-axis system, gas control system, electric control system, transmission system, protective casing, safety system, etc. of the laser cutting machine are collectively referred to as the host. When the laser cutting machine is cutting, first place the workpiece on the worktable, and then use the servo motor to drive the beam to control the movement of the Z axis. Users can adjust the parameters according to their own needs.

2. Laser: It is the core component of the laser cutting machine and the “power source” for the laser cutting machine to realize the cutting operation. Compared with other types of lasers, the fiber laser used by Hugong laser cutting machine has the advantages of higher photoelectric efficiency, longer service life, less maintenance, and lower cost.

3. Cutting head: The cutting head of the laser cutting machine is a laser output device, which consists of a nozzle, a focusing lens and a focusing tracking system. The cutting head of the laser cutting machine will walk according to the set cutting trajectory, but in the case of different materials, different thicknesses, and different cutting methods, the focus position of the laser cutting head is automatically controlled by the CNC.

4. Water cooler: The water cooler is the cooling device of the fiber laser cutting machine, which can quickly and efficiently cool the laser, spindle and other devices. The current chillers all contain the advanced functions of input and output control equipment switches and cooling water flow, high and low temperature alarms, and the performance is more stable.

5. Servo motor: Servo motor refers to the engine that controls the operation of mechanical components in the servo system. The servo motor can control the speed and position accuracy very accurately, and can convert the control signal into speed and position to drive the control object. High-quality servo motors can effectively ensure the cutting accuracy, positioning speed and repeat positioning accuracy of the laser cutting machine.

6. Air supply system: The air supply system of the laser cutting machine mainly includes air source, filter device and pipeline. The gas sources include bottled gas, liquefied gas, and compressed air.

7. Control system: It mainly controls the machine tool, realizes the movement of X, Y, and Z axes, and also controls the output power of the fiber laser.

Therefore, the above parts are important components of the laser cutting machine, and the components of the laser cutting machine are still different due to different models and brands. Therefore, when purchasing a laser cutting machine, it is necessary to combine Have an in-depth understanding of the brand, reputation, actual operating scenarios and uses of the laser cutting machine, and then choose the laser cutting machine that suits you according to the production use and usage scenarios of the enterprise

3015 Cnc fiber laser cutting machine Advantages.

1、Good flexibility, new product development without re-moulding, greatly shorten the development time of new products and reduce the cost of development.

2, High speed and high quality laser cutting of carbon steel, stainless steel, copper, aluminium and other metal materials.

3、Fast, high precision, what you see is what you get.

4、One time forming, avoiding multiple processing such as cutting and grinding of traditional processing, saving cost and improving efficiency.

Advantage: economical price, strong performance, suitable for small sites or small processing volume but the demand for fibre laser cutting and struggling start-up enterprises.

7 major features of fiber laser cutting machine

1. Ultra-low cost, the laser power consumption is only 0.5-1.5 degrees per hour; it can cut various metal sheets by blowing air.

2. High performance, imported original packaged light intensity laser, stable performance, service life up to 100,000 hours.

3. High speed, high accuracy, the cutting speed of thin plate can reach ten meters per minute.

4. The laser of the fiber cutting machine is maintenance-free.

5. The quality of the cutting edge is good, the deformation is small, the appearance is smooth and beautiful.

6. Imported guide transmission mechanism and servo motor are adopted, and the cutting precision is high.

7. Various graphics or text can be designed and cut instantly, the operation is simple, flexible and convenient.

Fiber laser cutting machine how to choose the best speed to cut high quality materials

Fiber laser cutting machine how to choose the best speed to cut high quality materials

The power of the laser affects the speed at which the laser machine cuts the sheet, and the cutting speed of the laser machine affects the quality of the sheet cut. Under certain conditions of laser power, there is an optimal range of cutting speeds, too fast or too slow will have an impact on the surface flatness of the cut material.

Excessive cutting speed

1. The laser beam and the material are in contact with each other for a short time, which may result in uncutting and sparks.

2. Some areas can be cut, but others cannot.

3. Causes delamination of the entire cut section.

4. The result is that the plate cannot be cut off in time, the cut section shows a diagonal striped path and the lower part produces melt stains, as shown in the figure below.

Cutting speed is too slow

1. The time taken for the material and the laser to interact with each other increases, resulting in over-melting of the cut sheet and a rougher cut section.

2. The cutting slit will widen accordingly, causing overburning in smaller rounded or sharp corners and not getting the desired cutting effect.

3. Low cutting efficiency, affecting production capacity.

Cutting speed judgment method

1. reasonable cutting speed: cutting sparks are spread from top to bottom, the cutting surface presents a smooth, lower no slag.

2. cutting speed is too fast: cutting sparks are tilted.

3、Cutting speed is too slow: cutting sparks show no diffusion and less, cohesion together.

CNC fiber laser cutting machine laser using environmental considerations

Define condensation.

The gradual reduction of the temperature of an object by placing it in an environment of a certain temperature, humidity and pressure. When the temperature around the object drops below the “dew point temperature” of the environment, the moisture in the air gradually reaches saturation until water dew is precipitated on the surface of the object, a phenomenon known as dew condensation.

Defining the dew point temperature.

Dew point temperature: from an application point of view, the temperature at which the air around the working environment precipitates “condensation dew” is the dew point temperature.

Avoiding dew

Avoiding condensation in the internal and external environment of lasers that are not self-contained

Damage to the laser caused by condensation in the internal environment is not covered by the laser’s normal warranty!

If a laser without air conditioning is used and exposed to the working environment, moisture can precipitate onto the electrical and optical modules once the cooling temperature falls below the dew point temperature of the laser’s internal environment. If this is not done, condensation will start to follow on the laser’s external surface. Therefore, once condensation is visible on the laser housing, it means that the internal environment is already condensing. Work must be stopped immediately and the working environment of the laser improved immediately.

Laser requirements for cooling water

The temperature of the laser cooling water must be set above the dew point temperature of the most demanding operating environment.

Avoiding condensation in the internal and external environment of self-contained lasers

Lasers with their own air conditioning may still cause condensation in the internal environment

When using a laser with its own air conditioning and exposed to the working environment, the cooling and dehumidifying effects of the air conditioning can significantly reduce the dew point temperature of the laser’s internal environment. Industrial air conditioners are generally set to the same cooling temperature as the cooling water temperature.

When the ambient temperature is below 38°C, the industrial air conditioner is able to maintain a safe environment inside the laser, but there may be condensation on the surface of the laser housing. If the condensation does not form flowing water droplets it is safe, if there is a large amount of flowing water droplets and there is visible water damage in the ground around the laser, another safe non-condensing working environment must be established for the laser with air conditioning.

When the ambient temperature is above 38°C, the cooling capacity of the industrial air conditioner is not sufficient to maintain the safety of the laser’s internal environment and condensation will still occur in the internal environment, and over time the external environment will follow suit. Therefore there should be no obvious heat sources around the laser and the hot air outlet of the water cooler should not be facing the laser.

To eliminate the risk of condensation inside the laser, it is recommended that the laser is equipped with a separate air-conditioned room.

Avoiding environmental condensation inside the processing head

If processing is not normal during the season or when the temperature changes significantly on the same day, you can check if dew condensation is occurring in the processing environment.

Use of dew point temperature look-up tables

Training end-users to use the dew point temperature look-up table can help to reduce the risk of condensation inside the laser and the process head.

The left-hand side of the table shows the current working temperature and the top side shows the current working humidity. The temperature at the intersection of the temperature and humidity parameters is the “dew point temperature” of the environment. This means that any object in this environment that is below this dew point temperature will have condensation on its surface. The principle of regulation is therefore as follows.

Dew point temperature look-up table

The way to avoid condensation is to reduce the temperature difference between the laser’s operating environment and its cooling temperature.

Fiber metal laser cutting machine winter use precautions

Fiber metal laser cutting machine winter use precautions

Thank you for choosing and using CNC laser cutting equipment, winter is approaching, most cities in China will enter sub-zero temperatures, in order to avoid damage to equipment caused by icing of the coolant, we provide you with technical information and solutions for anti-freezing.

A, the use of antifreeze

The base liquid of antifreeze is generally composed of alcohols and water, requiring high boiling and flash points, high specific heat and conduction capacity, low temperature viscosity, not easy to blister, and not corrosive to metal parts and rubber hoses. When choosing or blending antifreeze, its freezing point should be 5°C lower than the minimum temperature of the environment in which it is used.

It is recommended that you use a professional brand of specialised antifreeze.

We recommend the CLARIANT brand of antifreeze for use in laser systems

Note: Any antifreeze solution is not a complete substitute for deionised water and cannot be used for long periods of time throughout the year.

Deionised water or pure water must be used to clean the pipeline after winter and resume the use of deionised water or pure water as a coolant.

Second, the cooling water emptying method

If you do not use the machine for a long time, we recommend that you empty the coolant inside the equipment, the operation method is as follows.

1. Use 0.2Mpa~0.3Mpa nitrogen or clean compressed air to drain the coolant from the laser and QBH fiber; after there is no water flowing out of the drain, keep blowing for 2min to ensure clean discharge and ensure the safety of the laser system. Jinan Ding Point CNC Equipment Co.

2. The water cooler drain is always open, empty the remaining water in the chiller tank, if necessary, you can tilt the chiller at a certain angle to make the drainage cleaner, clear the pump head, the internal pipeline of the chiller and the water stored in the filter.

3. Drainage of the external piping: Blow with compressed air from the inlet and outlet for 1 minute to remove water from the piping. the water in the lines.

Note: All cooling water must be drained from the laser, laser output head, processing head and water cooler in order to effectively protect the entire water cooler. The laser, laser output head, processing head and all cooling water in the water cooler must be drained in order to effectively protect the entire water cooling line and related components!