china professional tube laser cutting machine manufacturer

- 首页

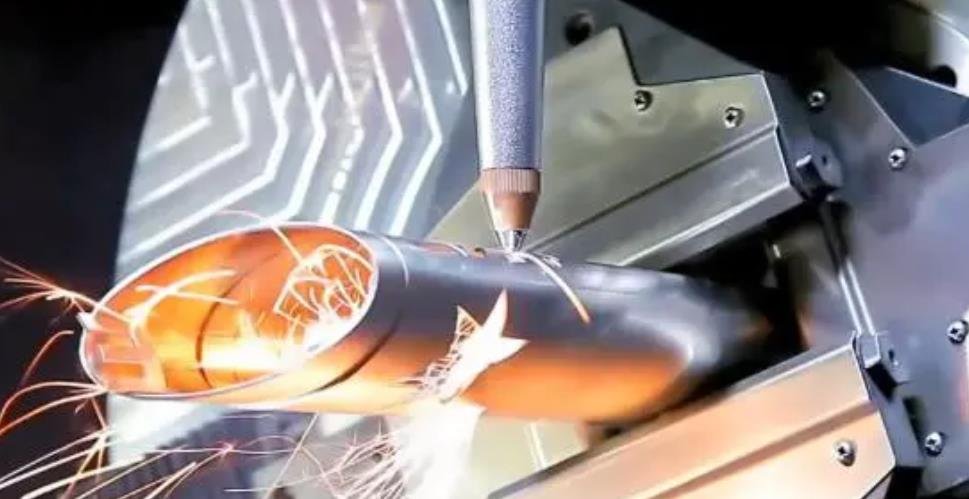

- wholesale metal tube laser cutting machine

The best 1000w 1500w 2000w 3000w metal tube laser cutting machine cost of sales

Model: 1000W 1500W 2000W 3000W metal tube laser cutting machine

Category: metal tube laser cutting machine

Brand:SUNSHAN

Sale Price: $38500.00 / Set

Price Range: $30000 to $200000 / Set Based On The Features

Supply Ability: 100 Sets / Month In stock!

1000w 1500w 2000w 3000w metal tube laser cutting machine it is suitable for all kinds of round, square, rectangular, flat, U-shaped and shaped tubes, etc. Meanwhile, it can make cutting process such as punching, beveling and micro connection while cutting. We can offer you metal tube fiber laser cut machine with affordable price.

metal tube fiber laser cutting machine for sale

3 advantages of metal laser pipe cutting machine.

1、Multiple cylindrical intersection holes of different directions and diameters can be cut in the main pipe to meet the conditions of eccentric and non-eccentric vertical intersection of the branch pipe axis with the main pipe axis.

2、Can intercept the end of the cylindrical intersection line at the end of the branch pipe to meet the conditions of eccentric and non-eccentric vertical intersection and oblique intersection of the branch pipe axis and the main pipe axis.

3、Ability to cut the oblique end face of the end of round and square pipe fittings, and can cut various hole types on round and square pipes to meet various processing requirements.

Square stainless stee tube laser pipe cutting machine video

CNC rectangular tube laser cutting machine video

Metal tube laser cutting machine Parameters

Max.outside diameter of round tubes(mm) | 20-210(Customized to 250) |

Pipe thickness | Depends on the power |

Cutting speed | Cutting speed: Max 0.8s/cut(Depending on material thickness) |

Y axis single feeding length | 1200mm |

Z axis adjustment range | 65mm |

W axis adjustment range | 360° |

Machine repeat positioning accuracy | ±0.05mm/1000mm |

Machine positioning accuracy | ±0.1mm |

Machine idle speed | 120m/min |

Maximum acceleration | 1.0G |

Electricity demand | 380V 50Hz(customizable) |

Cutting accuracy | ±0.1mm |

Machine size | 9340*1560*1615MM |

Machine weight | 8T |

Power | 500-8000w(Optional) |

Accuracy | ±0.1mm |

Max . raw material length (mm) | ≤6200 |

Max. finished part length (mm) | 1200 |

Pipe remain length (mm) | 180 |

Multi-funtional cutting | Mitre cut, rectangular, slot, square, circular, cold mouth, special profiles |

Power | Stainless Steel | Carbon Steel | Copper/AL | |

500w | 0.2mm-2mm | 0.2mm-5mm | 0.2mm-1mm | |

750w | 0.2mm-3mm | 0.2mm-6mm | 0.2mm-2mm | |

1000w | 0.2mm-4mm | 0.2mm-8mm | 0.2mm-3mm | |

1500w | 0.2mm-6mm | 0.2mm-10mm | 0.2mm-4mm |

CNC CONTROL SYSTEM

laser cutting control system of an tube laser cutting control system. Widely used in the field of metal and

nonmetal laser cutting. Because of its outstanding performance in the field of fiber laser cutting, by the vast number of high-end users.

Laser Head

With Anti-Crash Function, Good sealed, high pressure resistant, auto-tracking system and anti-crash and stop system can protect good cutting quality and longer the life of lens.

Fiber Laser Generator

1.Photoelectric conversion rate is up to 25-30%.

2.Low electric power consumption, it is only about 20%-30% of traditional CO2 laser cutting machine.

3.we have three kinds respectively Raycus, Max, and IPG.

What materials can be cut by metal tube laser cutting machine

Widely used in cutting stainless steel,carbon steel, manganese steel, spring steel, titanium alloy, galvanized sheet, aluminum plate, brass, copper and other metal material.

Ultra-high type, special metal material cutting.

Used for metal round, square tube, L kshaped metal, H Shaped metal, etc

CNC metal tube laser cutting machine Main Features

1.High Efficiency–The rapid cutting speed is two times higher than normal laser cutting machine.

2.Environment friendly–Laser cutting will not creates any gases for the special cutting technology for steel sheet.

3.Lower Consumption–The power consumption is 20%-30% lower than ordinary laser cutting machine.

4.Maintenance-free–For the fiber laser cutter, the reflect lens are no needed. It will help to save a lot of time when optical path is adjusted. The laser generator with longer lifetime which no need maintaince during usage

Metal laser tube cutting machine applications

Applied in sheet metal processing, aviation, spaceflight, electronics, electrical appliances, subway parts, automobile, machinery, precision components, ships, metallurgical equipment, elevator, household appliances, gifts and crafts, tool processing, adornment, advertising, metal foreign processing various manufacturing processing industries.

lighting industry

The current mainstream outdoor lamps and lanterns are large tubes, different kinds of cutting, and more and more vintage products, more and more types, the traditional cutting method is too low efficiency, and can not achieve personalized development, the use of laser cutting machine just to solve the problem.

fitness equipment

As the country attaches importance to sports health and personal health concept development, square fitness equipment and home fitness equipment, etc. are rapidly developing, the demand is particularly large, basically some pipe class cutting, the use of pipe laser cutting machine is very convenient and fast.

the advertising industry

Advertising industry due to customization is very much, using traditional methods of low efficiency, laser cutting machine is very suitable for the industry, no matter what kind of words, no matter how many different companies, are able to quickly cut out.

kitchenware industry

Now more and more houses, more and more decoration, kitchenware-related products are increasingly in demand, laser cutting machine is very suitable for cutting thin stainless steel, fast, high precision, good results, and can achieve customization and personalized product development, deep kitchenware manufacturers love.

How much is the pipe tube fiber laser cutting machine cost price

The price of CNC metal laser pipe cutting machine varies between 30,000 – 80,000 USD million, depending on what brand you need.

Fiber laser pipe cutting machine not only price difference, in the selection of the selection method should also learn to select. Laser cutting quality can be measured by the following six standards: cutting surface roughness, slag hanging size, cutting edge verticality and slope, cutting edge rounding size, the amount of drag after the stripe, flatness.

China CNC pipe tube laser cutting machine related issues

1, with a high and low exchange platform, an exchange of only 15 seconds, European standard design, high-end atmosphere, to enhance the corporate image.

2, simple all-in-one design: the laser air conditioning room design, longer life.

3、Every detail is striving for perfection, the operation table, stainless steel wrapping, we will build industrial products with the requirements of luxury goods.

4, The bed adopts 600 ℃ high temperature heat treatment, 12 meters gantry milling finishing, 24 hours with the furnace cooling, to ensure long-term use of the machine does not deform, the speed of up to 1.5G. 5, first-line brand laser, multi-module design, 100,000 hours of life.

6, SUNSHAN standardized plant, spot supply, high cost performance, stable performance, 7*24 hours after-sales response.

1, you need to process the equipment is not a laser tube cutting machine can process the range, such as pipe type, thickness, etc.

2, the laser cutting machine process is not to meet your operational requirements

If these two factors you do not examine clearly, even if metal tube fiber laser cutting machine price is cheap, you buy the tube pipe fiber laser cutting machine equipment can not meet your processing use, it is very expensive for you!

So laser pipe cutting machine purchase need to consider their own use of the use of demand!

Laser pipe cutting machine is used in pipe processing industry. The laser pipe cutting machine in the market can be divided into two categories: plate and pipe integrated machine and professional pipe cutting machine.

According to the cutting capacity or function classification, it can be divided into single platform plate and pipe integrated machine, exchange platform plate and pipe integrated machine, professional laser pipe cutting machine, semi-automatic laser pipe cutting machine, and automatic laser pipe cutting machine.

The price of various products will vary, and you will usually choose the right model according to your needs

Advantage one: save labor, improve production efficiency and good cutting effect.

The traditional process of processing pipe workpiece needs to be cut with a saw machine, then use a drilling machine or punch machine to process the hole, then chamfering and burr work, each process can not be seamlessly connected, each process of processing pipe or workpiece move once, in fact, will do a lot of useless work, a waste of labor and time costs. Laser pipe cutting machine processing pipe is a one-time molding, 6 meters of pipe placed on the machine just click to start, all the openings and cuts on the workpiece are formed at once, processing finished products, no burr.

Advantage two, not affected by the mold, can cut any shape, speed up the development of new products in various companies.

The saw blade is the most common pipe cutting link in traditional industrial pipe processing. The price of saw blades is around 1000 RMB. The service life varies depending on the worker’s proficiency and frequency of use. In addition, during the cutting process, cutting fluid is applied to cool the saw blade to prevent it from cracking. After cutting, each factory has different options. For useful drill presses, the drill press is more suitable for drilling long holes. For square holes and holes with corners, they are not easily machined. For useful punching machines, punching machines are more suitable for multi-hollow workpieces of the same size. The spacing between a single hole and space should not be too large. Generally speaking, the traditional equipment processing of tubing is only suitable for small batch rough machining. Laser tube cutting machine can solve these problems well, and all shapes made on the drawing can be processed on the laser tube cutting machine.

Advantage three: reduce environmental pollution and noise pollution.

Traditional processing workshop a variety of equipment running very noisy, the workshop needs to communicate loudly, may not be able to hear clearly, the cutting fluid used in the cutting process will also cause a lot of environmental pollution, laser cutting machine will not appear this phenomenon, laser cutting machine work sound is very small, may be similar to the car idling sound, will not affect people’s communication.

In the past, in the factory, if you want to cut such a large diameter steel pipe, you can only use the sawing machine. But sawing is very limited and can only cut in a straight line. If you want to cut at an oblique angle, you need to use the coherent cutting method. But the above two processing methods are relatively large tolerances. And the processing speed is very slow and the production efficiency is low.

Now the more advanced processing method, is the use of laser cutting. The advantages of laser cutting steel pipe are: high accuracy, cutting tolerance of up to 1mm, and processing speed is very fast, 500mm diameter round pipe, cutting a circle only takes a few tens of seconds. The processing time of sawing machine and coherent line is up to ten minutes. And laser pipe cutting machine processing, you can bevel cutting, open holes in the body of the tube. Again the speed is very fast and the cutting is very precise. Therefore, advanced processing plants in China are now using CNC metal laser pipe cutting machine to process all kinds of steel pipes. Laser pipe cutting machine, can cut iron pipe, carbon steel pipe, galvanized pipe, aluminum alloy pipe, stainless steel pipe and some composite metal material steel pipe.

One: input failure

1. If the automatic pipe cutting machine runs to a certain position and does not move, it is necessary to check whether the position switch at that position is in contact or damaged.

2. Another way is to touch the travel switch while ensuring safety and observe whether the plc input indicator responds. Accordingly, you can determine whether the travel switch is normal.

Second: output failure

1. If the automatic lack of a certain action, please stop and switch to manual mode first to open this action. If the automatic pipe cutter still does not respond, it is possible that the output relay has been damaged.

2. Manually open the action, observe the relay indicator, confirm that the action corresponds to the relay, replace it from the side or unplug it for replacement, if the action is normal, it is a common output relay loss.