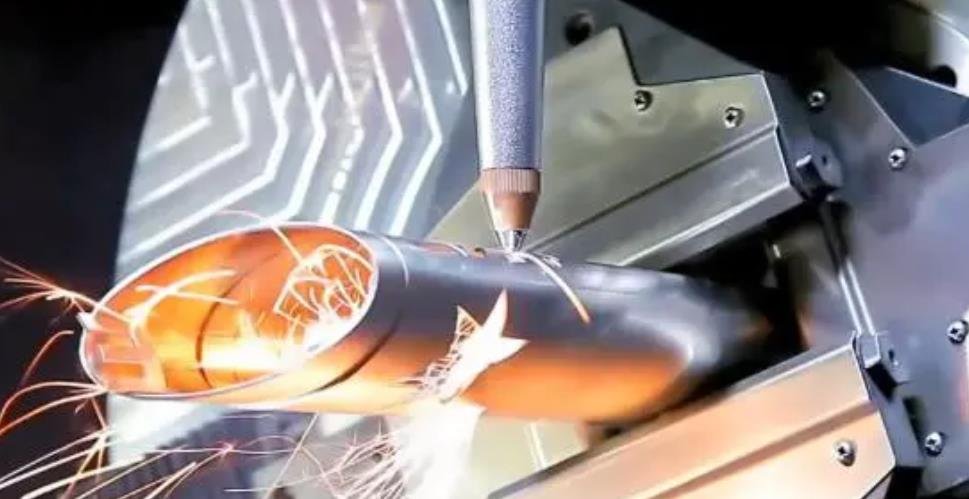

China CNC laser cutting tube machine manufacturers

Professional fiber laser cutting machine manufacturer to provide you with one-stop metal cutting solutions

- Cutting fast as lightning, stable performance, not easy to deform

- Various process processing, cutting, cutting, bevel cutting, hole opening, 45 degree cutting, cutting, bevel cutting and splicing can be realized

- Can cut stainless steel pipe, carbon steel pipe, iron pipe, seamless pipe, galvanized pipe, etc.

Why choose our tube laser cutting machine

Factory direct sales

12 years of manufacturing experience,We have our own factory and support customization

Competitive Price

Get a more affordable tube laser cutting machine to reduce costs.

Professional after-sales team

We have a professional after-sales team responsible for product installation, inspection and maintenance.

What is metal tube laser cutting machine ?

Tube laser cutting machine (laser tube cutting machine, stainless steel laser tube cutting machine, carbon steel tube laser cutting machine, CNC tube laser cutting equipment) can cut most metal tubes, stainless steel tubes, round tubes, square tubes, special-shaped tubes, channel steel and other metal pipes.It can achieve higher cutting accuracy and efficiency, improve production efficiency, save time, and facilitate user operation and maintenance.

CNC laser tube cutting machine for sale

CNC laser cutting tube machine Parameters

- Accuracy: ±0.1mm

- Maximum acceleration:1.0G

- Pipe remain length (mm):180

- Cutting accuracy: ±0.1mm

- Machine idle speed:120m/min

- Voltage/power: 380V/50HZ / 10KW

- Power: 1000W 1500W 2000W 3000W

- Machine positioning accuracy:±0.1mm

- Max . raw material length (mm):≤6200

- Max. finished part length (mm):1200

- Machine repeat positioning accuracy:±0.05mm/1000mm

- Cutting speed:Max 0.8s/cut(Depending on material thickness)

- Multi-funtional cutting:Mitre cut ,rectangular ,slot,square, circular ,cold mouth ,special profiles

Fiber laser pipe cutting machine product features:

Special laser, good cutting section and fast cutting speed.

Linear motor platform, full feedback system, fast platform speed and high precision.

Adopt high-precision visual positioning system, high positioning accuracy.

The dust extraction effect of the machine is good, and the full sheet metal protection and dustproof effect of the platform is good.

The machine is compact in structure, small in size and space-saving.

Optional small material and long clamps are optional, with high applicability.

It adopts Meike laser customized control system, which has the characteristics of high reliability and humanized operation.

The selection of high-quality fiber laser generator, photoelectric conversion efficiency of over 30%, and high-quality laser light source mode ensure good cutting effect and efficient processing efficiency, and greatly reduce laser energy consumption.

Laser tube cutting machine composition

Laser pipe cutting equipment consists of laser generator, control drive system, pipe laser cutting machine tool, light guide external light path system, cutting head, table, guide rail, pneumatic rotary fixture, mobile rotary fixture, automatic loading and unloading device, chiller, cold dryer, regulated power supply, etc.

High precision machine bed

1. Fiber laser cutting machine lathe bed part completely independent research and development, by the party welding lathe bed

base, through the large gantry milling machine. 2. For large machine bed we have many years of experience in processing, each

machine bed will be placed 30 to 45 days after rough machining natural failure, the internal stress release completely again after

finishing, ensure the machining accuracy. High strength, stability, ensuring 20 years of use without distortion

Laser Head

1. Optimized design structure: modularization, easy maintenance, and reduced downtime.

2. Multiple protective lenses: 3 protective lenses, efficient protection of collimating focusing lenses.

3. Durable and durable: 2-way optical water cooling, effectively extending continuous working time.

4. Closed-loop step-by-step automatic focusing: A closed-loop stepper motor is used to effectively avoid losing steps. The

focusing speed is 100mm/s, and the repeatability is 1μm.

5. Fast piercing High speed cutting: 16mm low carbon steel, piercing time <6 seconds, cutting speed 0.6m/min.

Water chiller

1. Automatically adjust the temperature according to different working environment, no need to change settings parameters. Reduce

the temperature of the laser source and the laser head through water circulation, thereby protecting these two main parts.

2. The chiller has functions such as water flow protection and water temperature protection. If the chiller is not opened or the

water flow is insufficient, the laser will not be generated when the water temperature is too high, so as to protect the laser.

What materials can ftube laser cutting machines be applied

Material Application:Stainless steel, carbon steel, alloy steel, silicon steel, spring steel, aluminum, aluminum alloy, galvanized sheet, galvanized sheet, pickled sheet, copper, silver, gold, titanium and other metal pipe cutting.

Application field of pipe tube fiber laser cutting machine

Used in metal tube processing, aviation, aerospace, electronics, electrical appliances, subway parts, automobiles, grain machinery, textile machinery, engineering machinery, precision parts, ships, metallurgical equipment, elevators, household appliances, craft gifts, tool processing, decoration, advertising, metal processing, kitchen processing and other manufacturing

and processing industries.

Advantages of fiber laser tube cutting machine

1. Automatic cutting and blanking; the pipe laser cutting machine adopts a double-drive pneumatic chuck rotating structure (driving shaft and driven shaft), the driving shaft starts the chuck to clamp the pipe and fix it, and then the pipe is processed by the three-dimensional movement of the machine tool. For cutting, the driven shaft starts the chuck to move along the axial direction of the workpiece with the worktable, and the automatic cutting and blanking function of metal pipes can be seen.

2. CNC cutting technology; advanced cutting technology and rich cutting experience are provided in the cutting control software that comes with the tube laser cutting machine, so that cutting operators can achieve high-quality and high-efficiency CNC cutting through skilled use of the control system.

If you need tube laser cutting machine manufacturers in china, we are here to support you. Contact us today!

China metal tube cutting laser machine Factory

We can offer you the best and most affordable price for cnc laser cutting machine for metal tube, and if you need sheet metal prototyping, we’ve got your back. Contact us today!

Collection of cnc tube laser cutting machine Questions

Do you have after sales support?

Yes, we are happy to give advice and we also have skilled technicians available across the world, We need your machines running in order to keep your business running.

The 4 main features of CNC laser pipe cutting machine

1. High precision: Traditional pipe cutting is done manually, so each cutting part is different. Laser processing adopts the same fixture system and completes the processing design by programming software to complete multi-step processing at one time with high precision. In modern manufacturing, precision is very important. Laser processing and forming gives each part the same dimensions.

2. High speed: The laser can cut several meters of pipe in less than a minute, hundreds of times more than traditional manual methods, which means laser processing is effective.

3. Flexibility: With traditional processing methods, the laser can be flexible enough to handle a variety of shapes, allowing designers to create complex designs.

4. Batch processing: The standard pipe length is 6 m. Traditional processing methods require very bulky clamping, while laser processing can easily complete several meters of pipe clamping position, which makes batch processing possible.

The laser pipe cutting machine adopts imported special pipe cutting software with the core technology of efficient cutting, which is the fundamental guarantee to improve the cutting efficiency.

Can metal laser tube cutting machine cut aluminum tubes

Stainless steel tubes, steel pipe products, aluminum alloy tubes can be cut by laser, round hole cutting, square hole cutting, irregular pattern cutting. Cutting thickness up to 5mm approximately. Cutting speed, high production efficiency, long service life, simple operation, zero consumables only need to power, save energy, safety and environmental protection, zero pollution, cutting pipe without burr.

Laser pipe cutting machine price and manufacturer selection

With the continuous application of laser tube cutting machine in the pipe industry, a large number of uneven cnc laser cutting tube machine manufacturer emerged, at this time customers want to buy a round pipe laser cutting machine how to choose? Is it just the pursuit of low prices? Or to focus on the quality of fiber laser cutting machine tube manufacturer?

Automatic pipe cutting machine stainless steel pipe in the procurement process to pay special attention to the laser, cutting head, servo motor and other such small accessories, not only determines the automatic pipe cutting machine later is not cutting burr-free, there are pipe cutting machine price. Round pipe laser cutting machine later training and later in the use of the process will inevitably appear such and such problems, automatic pipe cutting machine manufacturer can not provide timely solutions is the focus of your later consideration. After all, you square steel pipe cutting machine equipment selection is good, you will really have no worries later, the use of the process is no trouble.

So later in understanding how much the laser pipe cutting machine with what tube laser cutting machine manufacturers reliable, not only to compare the price of laser cutting machine equipment, but also to consider the strength of the manufacturer, equipment performance, after-sales service more importantly, the main configuration of the laser pipe cutting machine, after all, good value for money laser pipe cutting machine is your What you really want is not it?

Metal laser fiber optic pipe cutting machine features.

Metal laser tube cutting machine to meet the requirements of users. Square pipe cutting and shaped processing. Realize the automation of pipe material . Underfeeding.

1. can cut several different directions on the main tube. Cylindrical coherent holes of different diameters to meet the vertical crossing conditions of branch pipe axis and spindle eccentric and non-eccentric.

2. Cylindrical coherent ends can be cut in the end of the branch pipe to satisfy the condition of vertical intersection of the branch pipe shaft with the eccentric and non-eccentric of the main shaft. Inclined intersection condition.

3. Capable of cutting oblique sections at the end of circular tubes.

4. Capable of cutting the ends of branch pipes that intersect with the annular main pipe.

5. Can cut variable angle bevel surface.

6. Can cut square holes in round pipes. Waist-shaped hole.

7. Can cut steel pipe.

8. Can cut various shapes on the square pipe surface.

What is a reliable laser tube cutting machine manufacturer

We SUNSHAN China laser tube cutting machine manufacturer as a professional laser tube cutting machine manufacturer, not only focus on the quality of the product, pay more attention to the after-sales service of the equipment, where the purchase of our laser equipment, 1years quality guarantee, the machine with main parts (including the consumables) shall be changed free of charge (some parts will be maintained) when if any problem during the warranty period. The machine with the main parts (including the consumables) shall be changed free of charge (some parts will be maintained) when if any problem during the warranty period.

5 factors affecting the price of metal laser tube cutting machine

1, brand awareness: of course, the brand size determines the price of equipment, which is a relatively abstract concept. We can understand it this way, the big brand, in the quality of equipment, equipment spare parts, equipment performance, technology, including after-sales service, will be much more secure than small factories, these are an added value of the product, but also a universal law of the laser pipe cutting machine market, and thus the big brand of laser pipe cutting machine will definitely be higher than the price of small brands.

2, machine width: laser tube cutting machine manufacturers generally have several specifications of the standard width size, and for the special needs of customers, can also be customized non-standard to meet the customer size of the machine. Standard size is the manufacturer has always made the specifications, while non-standard sizes need to be specially ordered, and thus the custom width to be more expensive than the standard width.

3, the brand of the laser: as we all know, the laser is the core optical components of the laser pipe cutting machine, laser pipe cutting machine brand varies, the quality of the beam also varies greatly, the price of the laser also varies with the brand and there are huge differences.

4, laser pipe cutting machine of other key components: other key components such as guide rails, rack and pinion, servo motors, etc., their brands and quality, is also the reason for the price varies.

5, power: the same brand of manufacturers, the higher the power of the equipment, the higher the price. Thus, before asking for quotations, be sure to be clear about the material you want to cut, thickness, and their needs for cutting speed, capacity.

In short, brand awareness is easy to induce customers to buy and sell laser pipe cutting machine, in fact, users in the purchase of laser pipe cutting machine, the brand, power, after-sales service should be combined with the three aspects of comparison, so that you will get the right laser tube cutting machine.

Do you have any other fiber laser tube cutting machine style?

Yes, please check the following fiber laser tube cutting machine style, if you have any questions, you can contact us any time, 24×7, we always here.

If we are interested in your cnc laser tube cutting machine, how do we choose?

1. What main job you do with the machine?

2. What is your request max length, __mm? max diameter, __mm?

3. What material you want to cut,stainless steel,carbon steel? Aluminum? or other?