China CNC tube cutting laser machine Manufacturers Suppliers

SUNSHAN offers a wide range of cnc laser tube cutter, cnc laser pipe cutting machine, and more. We used different cnc laser pipe cutting machine for mettal. Aside from that, SUNSHAN also offers sheet metal laser cutting machine. It also comes in customized sizes, thicknesses, and designs.SUNSHAN can manufacture cnc laser tube cutter according to your specification, details, and requirements. Send us your inquiries today!

cnc laser tube cutting machine manufacturer

CNC laser tube (pipe)cutting equipment consists of laser generator, control drive system, pipe laser cutting machine tool, light guide external light path system, cutting head, table, guide rail, pneumatic rotary fixture, mobile rotary fixture, automatic loading and unloading device, chiller, cold dryer, regulated power supply, etc. The equipment control system, laser cutting machine tool, laser and automatic feeding device are integrated and highly integrated with linkage CNC function.

cnc laser tube cutting machine for sale

cnc fiber laser tube cutting machine Parameters

- model:Affordable Metal Tube Laser Cutting Machine

- Laser Power:1000W/1500W/2000W/3000W/4000W/

- Pipe Processing Range:6000mm* φ10~220mm (Square tube: 10*10~150*150mm)

- Maximum Speed:100m/min

- Maximum Rotational Speed:100r/min

- Z-axis Travel:170mm

- Positioning Accuracy:±0.05mm

- Repeated Positioning:±0.02mm

- Maximum Acceleration:0.8G

- Table Maximum Load(KG):700

- Power Parameters:Three-phase AC 380V 50Hz

- Protection Level of Total Power Supply:IP54

What does the Affordable cnc Metal Tube Laser Cutting Machine cut?

Material | 1000W | 1500W | 2000W | 3000W |

Carbon Steel(mm) | 1-10 | 1-10 | 1-10 | 1-16 |

Stainless Steel(mm) | 1-5 | 1-6 | 1-6 | 1-8 |

Aluminum (mm) | 1-4 | 1-6 |

how much does a cnc laser cutter cost

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus.

Laser Generator

1.Photoelectric conversion rate is up to 25-30%.

2.Low electric power consumption, it is only about 20%-30% of traditional CO2 laser cutting machine.

3.we have three kinds respectively Raycus, Max, and IPG.

Touch control

Elegant curves precisely fit machine body. Strong waterproof breathable system creates the best space, making operation more convenient. Diamond cutting process and HD plasma tempered glass make screen more exquisite and comfortable to use. More enjoyable work methods and cheerful mood can improve work efficiency.

Cooling System

CNC CONTROL SYSTEM

laser cutting control system of an tube laser cutting control system. Widely used in the field of metal and

nonmetal laser cutting. Because of its outstanding performance in the field of fiber laser cutting, by the vast number of high-end users.

Professional Cutting Head

Easy operation, and support more language can be optional, Simplified Chinese, Traditional Chinese, English, Korean, Russian, Czech, German, Spanish, French, Italian, Japanese, Dutch, Portuguese, etc.

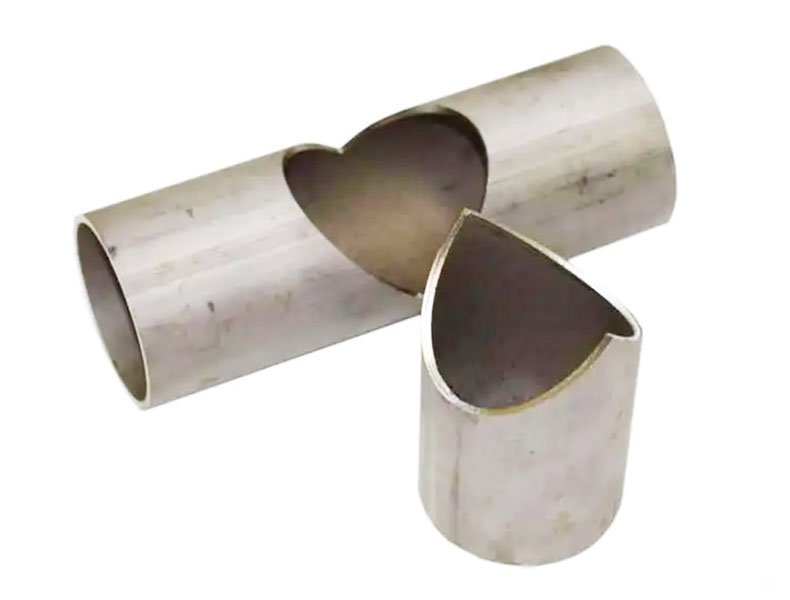

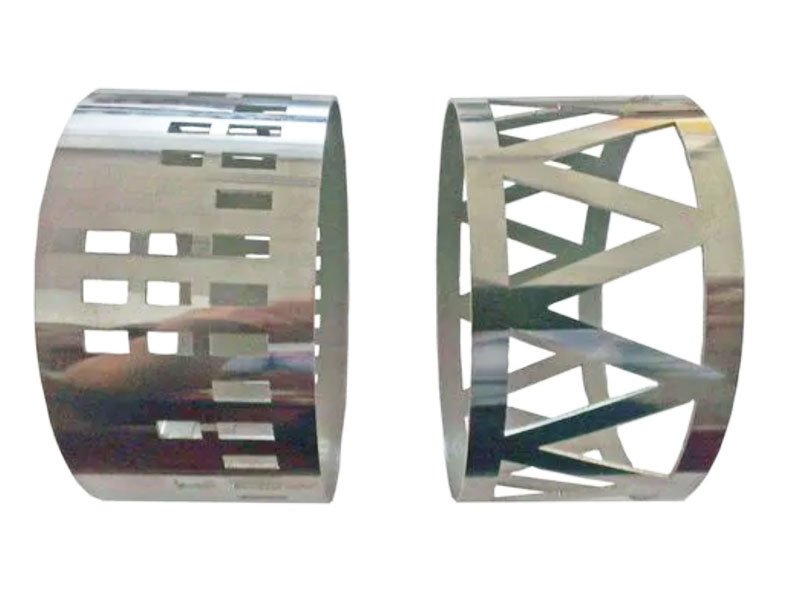

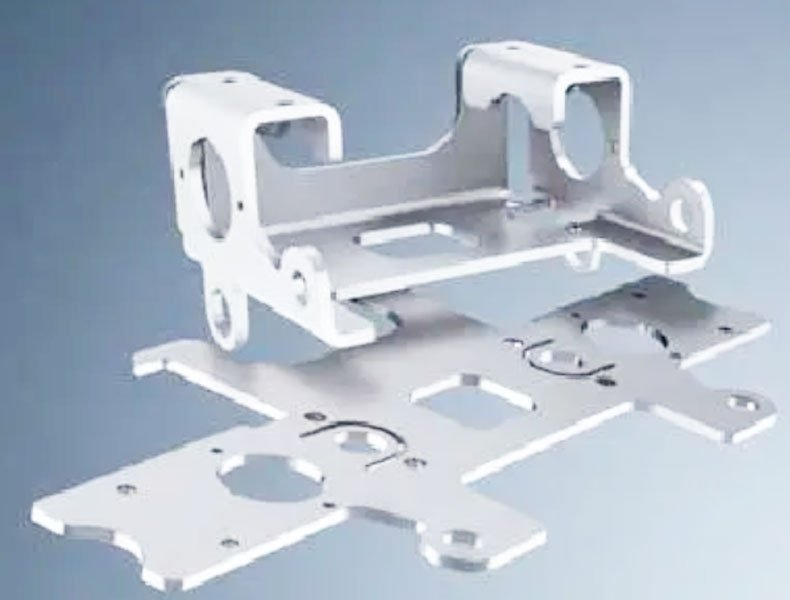

CNC Laser Tube Cutting product effect display

CNC Fiber Laser Tube Cutting Equipment is suitable for metal cutting like Stainless Steel Sheet, Mild Steel,

Carbon Steel, Alloy Steel, Spring steel, Iron, Galvanized, Galvanized, Aluminum, Copper, Brass, Bronze,Titanium,etc

Application field of cnc tube laser cutting machine

CNC Fiber Laser Tube Cutting Machines are widely used in manufacture Billboard, Signs, Advertising, Signage, Metal Letters, LED Letters, Kitchen Ware, Advertising Letters, Metal Cutting Processing, Metals Components and Parts, Ironware, Chassis, Racks & Cabinets Processing, Metal crafts, metal art ware, elevator panel cutting, hardware, auto parts, Glasses Frame, Electronic Parts, Nameplates, etc.

Why choose our cnc tube laser machine

Factory direct sales

12 years of manufacturing experience

Competitive Price

Get a more affordable cnc laser cutting machine for tube to reduce costs.

Professional technical team

Professional 1 to 1 technical support

The working principle of laser pipe cutting machine.

1. Loading rack: Before cutting starts, the whole bundle of tubes needs to be lifted manually to the placement rack, manually packed and dismantled, and placed on the automatic tube transfer mechanism in multiple branches in turn.

2. The tubes are placed on the conveying platform in turn. The tube conveying device can transfer the tubes to the feeding mechanism smoothly and regularly one at a time according to the requirements, and the tubes will be automatically replenished on standby according to the tubes.

3. The feeding mechanism will automatically transfer the tubes from the waiting area to the automatic feeding mechanism according to the signal, and other tubes will automatically fill and move to the material position to ensure continuous operation.

4. The tube positioning alignment system will align the tube position neatly as needed (the tube material should not be placed beyond the outside of the feeding mechanism).

5. The feeding structure automatically feeds the tubes to the machine material (lifting) shelving system on signal (one tube at a time).

6. The material feeding mechanism receives the signal that the shelving is finished and returns in time, while the A rotary clamping jaw device moves – clamps – advances to the B rotary disk for perfect cutting according to the signal.

7. The material shelving system automatically lifts up and down to avoid collision according to the distance of A rotary clamping jaw device.

8. When the A rotary clamping jaw device advances to the middle limit position of B rotary support disc, the C rotary clamping jaw device automatically runs to the right end of B rotary disc to continue the perfect cutting of the tail material, thus ensuring the overall cutting of the pipe and basically zero tail material.

9. Automatic lifting type catching system, rising to 15mm from the pipe rotation degree, catching the workpiece while the pipe is cut, avoiding the workpiece falling naturally due to the weight of the pipe, the gap at the cutting point is too large or falling deformation.

10. After the automatic lifting type receiving system receives the material, it will automatically drop to the fixed position, and at the same time, the receiving box will be tilted, and the workpiece will then naturally slide down to the ground material collection hopper.

11. The feeding mechanism is on standby to prepare the material before the previous pipe is cut, and is on standby for the next pipe processing operation procedure.

If you need fiber laser tube cutting machine factory, we are here to support you. Contact us today!

china tube fiber laser cutting machine Factory

We can offer you the best and most affordable price for cnc laser cutting tube machine, and if you need sheet metal prototyping, we’ve got your back. Contact us today!