China fiber laser pipe cutting machine Factory

Professional cnc pipe cutting laser machine manufacturers to provide you with one-stop metal cutting solutions

- Three-chuck zero-tail laser cutting machine can help users to realize automatic loading and unattended

- No need for manual monitoring, which reduces labor cost and improves production efficiency.

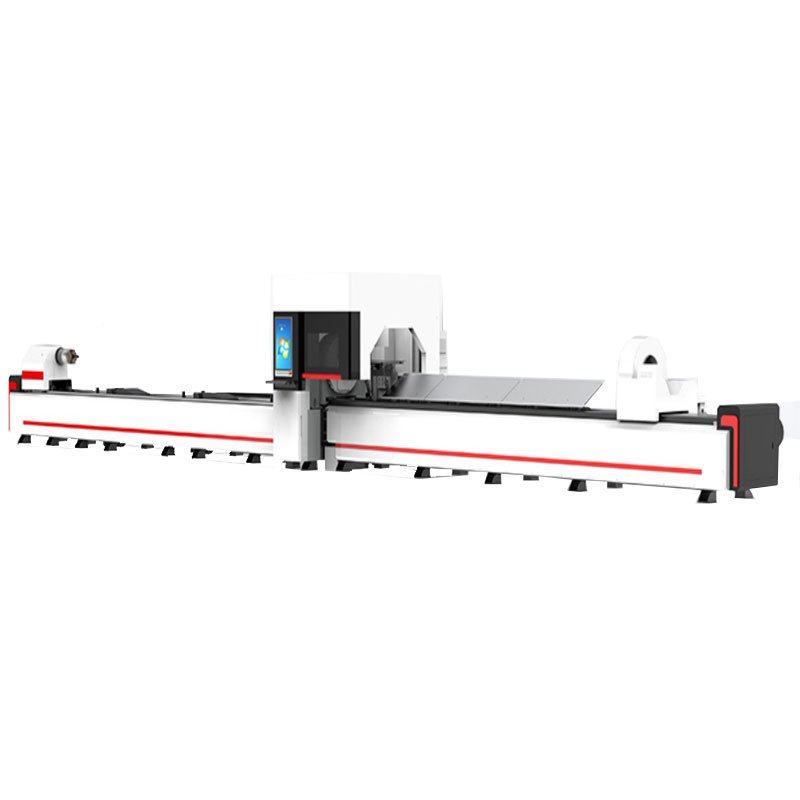

Three chuck zero tail laser pipe cutting machine for sale

Model: 1000w 1500W 2000w 3000w pipe laser machine cutting for sale

Category: pipe laser machine cutting

Brand: SUNSHAN

Standard price: from $300,000 (depending on configuration)

Availability: 30 sets per month in stock!

Three chuck laser pipe cutting machine manufacturer

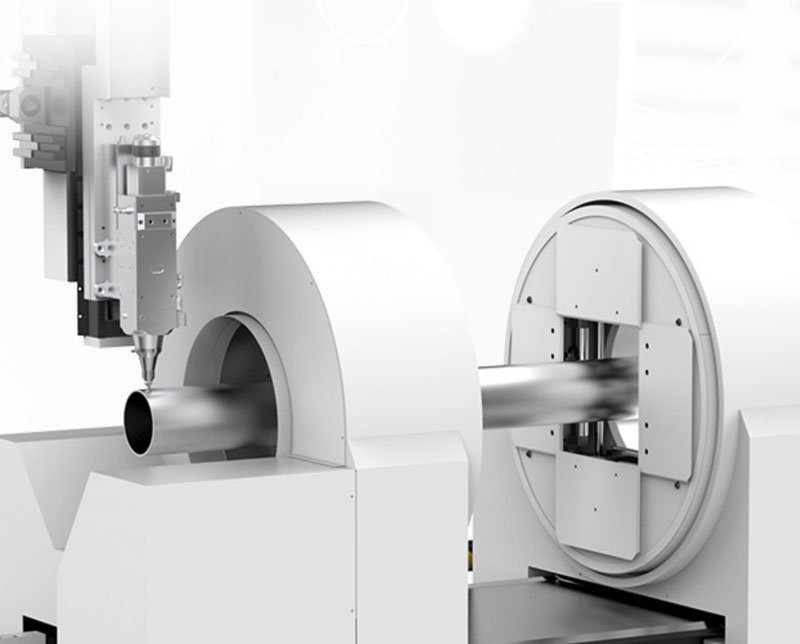

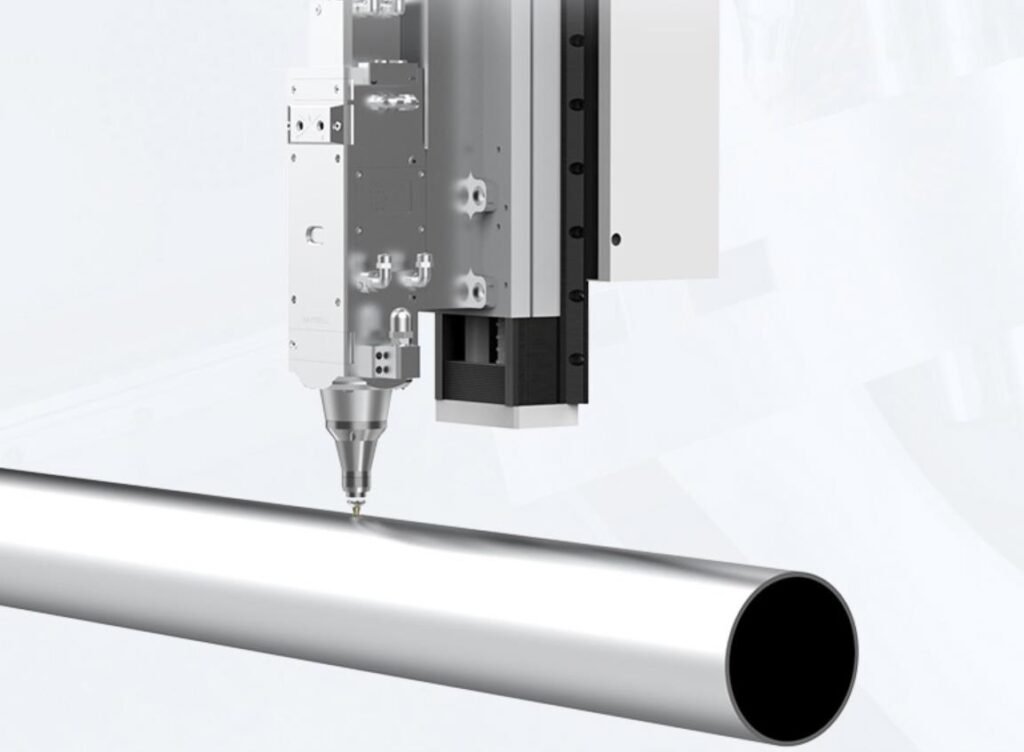

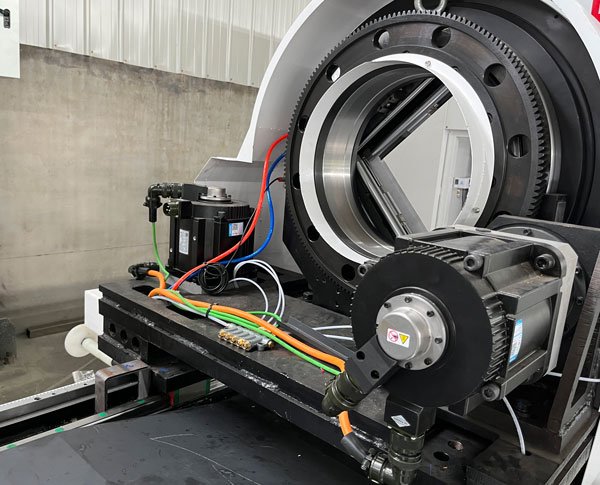

Three chuck 0 tailstock laser pipe cutting machine for eliminating tailstock, Y axis Z axis is mounted on X2 axis, the laser head can skip the middle card when cutting tailstock to achieve super short tailstock cutting. 2 chuck tailstock ≈ 50mm, 3 chuck 0 tailstock.

Equipment standard power support 1500-6000W, processing bed stroke 6-12 meters, pipe diameter 20-350mm, wall thickness 0-25mm.

According to the specific cutting needs can be optional automatic loading and unloading device, to meet a variety of different cutting needs, with a professional operating system, can simplify the programming nesting process, simple and convenient operation

Three chuck laser pipe cutting machine features.

The bed is made of steel plate tube cutting and welding, the bed, chucks and other major components are developed and designed and produced by our company.

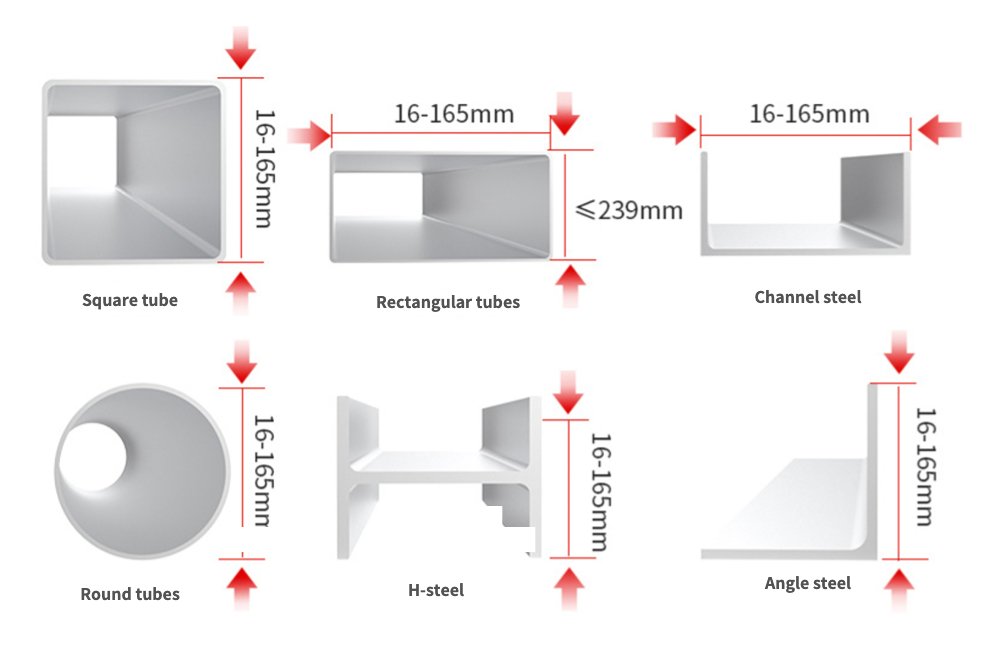

The machine is equipped with full-stroke pneumatic chuck and automatic loading and unloading system, which is suitable for all kinds of metal pipes of 16-345mm diameter and any shape.

Zero tail material laser pipe cutting machine can carry out three chuck common auxiliary clamping, cutting speed, high processing accuracy, material utilization rate and other advantages.

Cutting efficiency is equivalent to 2-3 times of traditional sawing or plasma cutting.

Sawing will cause deformation at the kerf of the pipe, the kerf has a slight bump, and the amount of consumables loss, maintenance trouble.

Plasma cutting has a large thermal impact, and the pipe kerf is prone to a large amount of deformation, and the accuracy is rougher compared to laser cutting.

best pipe fiber laser cutting machine Parameters

- Repeat Positioning Accuracy: ±0.03mm

- Positioning Accuracy: ±0.03mm

- Max Movement Speed : 100m/min

- Laser head: MAX,RAYTOOL

- Laser source:MAX/IPG/Raycus

- Materials thickness: 0-22mm

- Voltage/power: 380V/50HZ / 10KW

- Applicable Materials: steel,stainless,carbon steel,aluminum.etc

- Laser Power:1000W 1500W 2000W 3000W 4000W 6000W

Why choose our laser cutting machine

Factory direct sales

12 years of manufacturing experience

Competitive Price

Get a more affordable pipe laser cutting machine to reduce costs.

Professional technical team

Professional 1 to 1 technical support

Cutting product effect display

Zero tail material laser cutting machine is suitable for: metal square tube, round tube, rectangular tube, oval tube, waist-shaped tube, D-shaped tube, hexagonal tube and other shaped pipe cutting, support pipe truncation, cut holes, beveling, hollowing, cutting shape, etc. Our T series pipe laser cutting machine, is a professional for metal pipe cutting equipment.

Application field of fiber laser cutting machine

Widely used in electrical appliances, hardware tools, bathroom tools, instruments, automotive and motorcycle parts, cell phone communication components, precision instruments, medical machinery, IT digital metal shell, advertising signs, models, kitchen utensils and tableware and many other industries. The design of this machine adopts the ergonomic design principle, low operating costs and easy maintenance, no tail material cutting will become the inevitable trend of laser cutting process.

Wide range of pipe cutting

It supports the processing of 12000mm ultra-long whole workpiece, channel steel, angle steel, I-beam and other profiles, and the maximum load-bearing capacity of a single pipe is 900KG.

inovative three-chuck design

Intelligent control system

Cyptube cutting software is a set of software specially developed for the deep customization of the laser cutting industry.easy to use, rich in functions, suitable for various processing occasions.

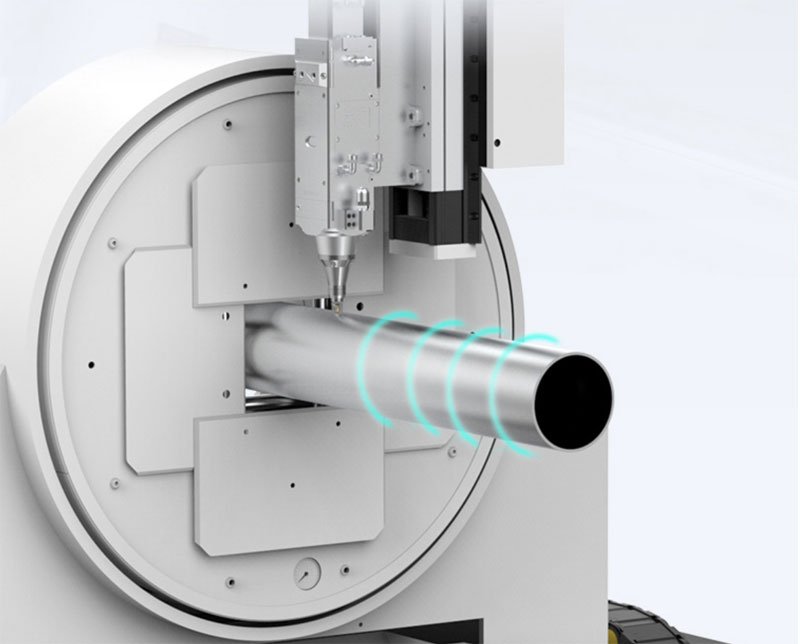

What we can offer you fiber pipe laser cutting machine factories

The three-chuck laser pipe cutting machine adopts the signal transmission mode of electricity-light-electricity. The light-emitting part and the light-receiving part are not connected to each other, which can effectively avoid interference from the output side to the input side and thus reduce the noise generation. The response time of the photocoupler is very short, some can even be less than 0.01μf, with the advantages of more durable, more reliable and faster. The circuit of this kind of pipe cutting machine is generally selected when the photoelectric coupling method to isolate the input signal circuit from the microcontroller.

The three-chuck tail-free laser pipe cutting machine is very inclusive of the pipe to be cut. Not only can they cut pipes of various lengths and thicknesses, but they are also suitable for many different materials and thicknesses of metal pipes, so that more industries can use this machine to reduce costs and improve efficiency for their businesses, providing more efficient skills to support all walks of life.

If you need metal pipe laser cutting machine factory, we are here to support you. Contact us today!

China cnc pipe cutting laser machine exporter

We can offer you the best and most affordable price for cnc metal pipe laser cutting machine, and if you need sheet metal prototyping, we’ve got your back. Contact us today!

Collection of pipe fiber laser cutting machine Questions

I don’t know which stainless steel pipe laser cutting machine is suitable for me ?

Please contact with us and tell us:

1) Your materials,

2) Max size of your material, 3) Max cut thickness,

4) Common cut thickness,

cnc pipe laser cutting machine use of precautions

Metal laser pipe cutting machine in the process of use will appear heat phenomenon, which will develop to cause some system failure. In order to can avoid the use of laser pipe cutting machine failure, pay attention to good maintenance and repair of the laser pipe cutting machine.

In order to avoid condensation, heavy humidity, frequent rainfall and poor humidity conditions can easily lead to condensation inside the laser. Many parts of the laser and cutting head are regulated by water-splitting cooling. It is recommended that the water temperature be set at about 26 degrees for the cryogenic laser and fiber, and 30 degrees for the cutting head and fiber, in strict adherence to the switching sequence.

Humid weather can make laser power laser equipment and parts appear wet, condensation, resulting in failure, affecting the normal production of users. Failure is due to maintenance and not part of the normal warranty, the above reasons improper.

Maintenance of the cooling control system and cooling water summer ambient temperature is rising, the laser pipe cutting machine cooling technology system management work life pressure gradually increased, it is recommended to check the maintenance of the cooling machine before the onset of high temperature internal press fluorine pressure, due to the different temperature requirements are higher, the deterioration of cooling water will also accelerate, it is recommended that corporate customers friends we use a regular distilled water or deionized water, regular cleaning of the water tank scale Replace the water and cartridge, so as not to cause the laser and the pipeline attached to the scale affects the analysis of cooling water flow caused by high temperature alarm, clean up the scale method please independent under the guidance of professional theory for practical operation.

Guide rail maintenance, rail should be cleaned regularly to remove dust and other debris to ensure that the lubrication device, no debris in the drive part. Laser pipe cutting machine regular cleaning and lubrication oil, can ensure the accurate positioning of the machine to obtain progress more accurate cutting and improve product quality.

Laser pipe cutting machine fast perforation technology

Laser pipe cutting machine fast perforation technology can cut a variety of complex seam type according to customer needs, while most other cutting machines are not able to complete such complex cutting operations, are only more complex work procedures of machinery and equipment, but can not cut such a variety of types of cutting patterns and seam type, and can not achieve the higher effect and role of a machine required in the production process. Machines using this technology are not only able to perform a variety of highly complex cutting tasks, but are also able to ensure smooth operations with as little harm as possible to the pipe during processing.

Laser pipe cutting machine fast perforation technology in the cutting process there is an important advantage is to produce less noise, which can reduce the work of the operator’s ears caused by damage to ensure efficient and smooth cutting can still be the premise of maintaining the health of the operator, so that workers can work more relieved to complete the cutting task quickly and efficiently!

Laser pipe cutting machine fast perforation technology can not only meet the cutting needs of a variety of pipe types, but also to ensure the smoothness of the slit, in addition to making the pipe more beautiful and accurate, such cutting technology can, to a certain extent, increase corrosion resistance, extend the service life of the pipe, reduce the frequency of pipe replacement and thus reduce costs.

If you are interested in our cnc laser cutting machine pipe exporters, you can consult us WhatsApp: 86-18654506392, to provide you with affordable stainless steel laser cutting machine equipment

Aluminum pipe laser cutting machine manufacturer service

Pre-sales management, SUNSHAN not only provides customers with professional information and consulting services on products, prices, technology and industry solutions, but also provides free samples and professional inspection reception services, and customers can visit the company site for field inspection at any time.

Sales management, both old and new customers, both domestic and foreign customers, WeiYang machinery treat all customers equally, in good faith, fair attitude, treat every customer with care, while each aluminum pipe laser cutting machine equipment ordered by the customer, strict control of product standards, multiple quality inspection to ensure customer satisfaction.

After-sales management, based on the user’s general concern about product installation. Warranty time and maintenance, repair and other issues, SUNSHAN meticulous planning of each process. Commitment to provide customers with free training, installation, 1-year warranty on the whole machine (except wearing parts) and lifelong maintenance and other services.

In addition to product quality, service level is also one of the factors that affect consumers to buy laser pipe cutting machine brand. For consumers to bring a better consumer experience.

3 tips to help you reduce the cost of using laser tube cutting machine

How to reduce the use of metal laser pipe cutting machine costs, is a lot of Wei Yang laser users are particularly concerned about a problem, SUNSHAN laser pipe cutting machine manufacturer for this problem, summarized the following recommendations.

Metal laser pipe cutting machine as a professional metal pipe cutting equipment, we need to choose the right model according to the actual situation of their own business, such as the power can not use too big, can not use too small, just right, because too much power will burn the pipe, too small will cause the cut does not move. Therefore, the selection of these machinery and equipment must be selected from the regular manufacturers, select the regular products.

Secondly, we use CNC metal laser pipe cutting machine, we can not be frequently turned on, because frequent start-ups will reduce the efficiency of the machine, with the equipment also exists loss, it is recommended that enterprises rational planning pipe cutting time, as far as possible, a one-time batch to complete the cutting task.

Then we also want to optimize the quality of pipe cutting, there are good pipe cutting equipment, but also well-trained operators, cutting out more high-quality workpiece, reduce the cost of waste and secondary processing.

The above 3 suggestions, I hope it can help you, for your business to save more costs. Now laser pipe cutting machine is widely used, many industries need, such as help hardware and furniture, auto parts industry, stainless steel products industry, bathroom building materials, sports equipment, security net and other industries to improve production efficiency, improve production quality, reduce production costs, which is more and more enterprises enterprises choose it.

How to provide stainless steel laser tube cutting machine quality

The size of the optical power will have an important impact on the laser processing, not the greater the power of the laser pipe cutting machine is better, to combine the tube’s own characteristics to choose the right laser power, so that the focus to obtain a better density, to achieve a more desirable cutting effect.

Laser cutting pipe to ensure that the cutting speed within a certain range in order to obtain a better cutting quality, too fast, there will be a pipe cut constantly or cut through the phenomenon, affecting the cutting quality, too slow, too much heat builds up on the surface of the tube, will burn the surface of the pipe mouth, cutting out will be very rough.

The characteristics of the tube itself will have a great impact on the laser processing process, different pipe diameter or pipe material with the same laser cutting, cutting out the effect will be different, such as the same diameter of copper and stainless steel pipe with laser to cut, copper pipe is not good to cut, stainless steel pipe is good to cut.

Auxiliary gas type and pressure will also affect the cutting quality of the pipe, when cutting the pipe wall thickness at a higher speed is small, the auxiliary gas pressure should be increased to prevent slagging of the kerf.

When cutting pipe wall thickness is larger or the cutting speed is slower, the pressure of the auxiliary gas should be reduced to prevent the pipe from not cutting through or not cutting.

Laser pipe cutting machine in the wind power industry

In recent years, under the dual pressure of conventional energy emergency and global ecological environment deterioration, the development of wind power industry and other high-quality clean energy has become a global consensus. What is the application of laser pipe cutting machine in the wind power industry?

The internal components of the wind power industry mainly contain I-beam, angle iron, round pipe, these internal components need to be cut. The traditional cutting method has been unable to meet the processing needs of the wind power industry, but the laser pipe cutting machine can.

The cutting range of I-beam in wind power industry generally reaches 250*250mm, angle iron generally reaches 100*100mm and round pipe generally reaches 330mm. a laser pipe cutting machine can complete these cutting needs, and the cutting gap is small, even seamless cutting, to meet the wind power industry’s high requirements for cutting components.

Laser pipe cutting machine effectively help wind power industry to solve the processing efficiency of slow, poor, long processing time difficulties, improve production efficiency, improve production quality, reduce labor intensity, a machine can meet the needs of multiple processes, widely welcomed by the wind power industry. For more information about laser cutting equipment, welcome to SUNSHAN, professional china pipe fiber laser cutting machine, square pipe fiber laser cutting machine

After-sales guarantee.

I am not convenient to go to china pipe laser cutting machine factory. But I want to see the condition of the machines in the factory

We support the production visualization service. The sales department who responds to your inquiry for the first time will be responsible for your follow-up work. You can contact him /her to go to our factory to check the production progress of the machine, or send you the sample pictures and videos you want. We support free sample service.