The rapid development of the industrial market, tube cutting in the industrial use of a wider range, many customers in China to purchase pipe laser cutting machine, there are many questions, laser tube cutting machine price is how much, which China tube laser machine suppliers for sale, now let sunshan laser tell you.

What is a cnc tube pipe laser cutting machine.

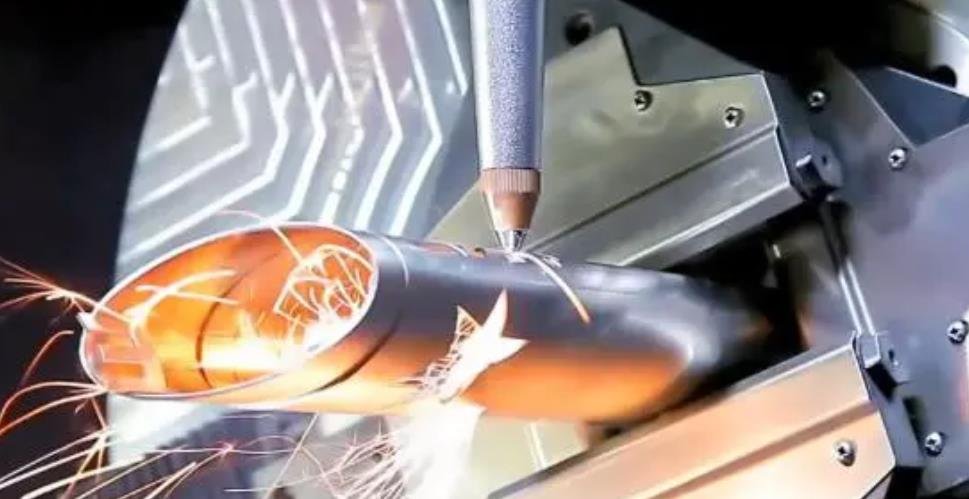

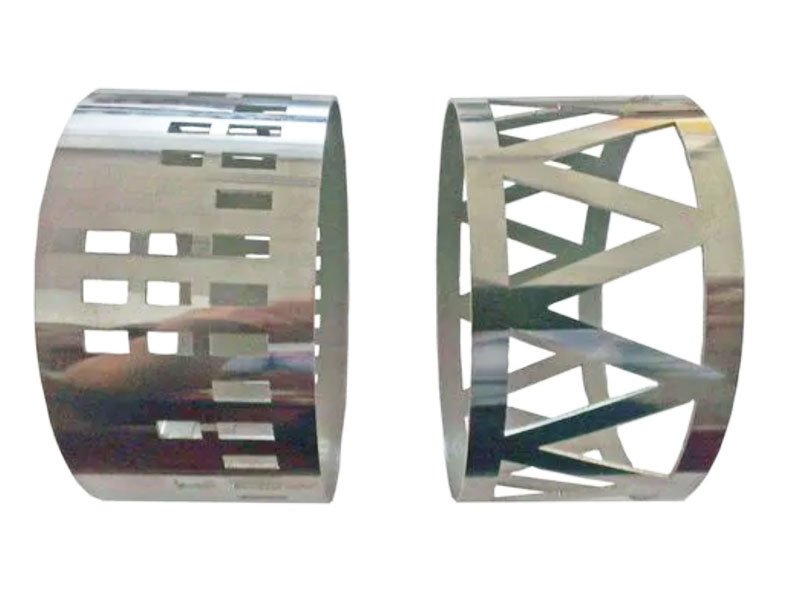

Tube laser cutting machine in the laser cutting, heat impact is small, the cut pipe almost no thermal deformation, no oxidation in the section. Automatic laser pipe cutting machine for small tubes can also do precision cutting, and there is no damage to the raw material, no burr in the cut, and the cut surface is flat. Laser pipe cutting machine has high working efficiency, can work for a long time, suitable for processing a large number of pipes, reduce the investment of labor costs, improve the input-output ratio of enterprises, so that enterprises can obtain profits in a short period of time.

What is the cnc laser tube cutter cost

The average cost of a metal tube laser cutting machine is about $30,000. This is the most basic laser tube cutter cost range. These machines can cut iron, steel, aluminum and other materials. Machines that can cut 1 inch thick material typically cost between $30,000 and $100,000.

The laser tube cutter cost can vary greatly depending on the features and cutting engines offered. There are many tube laser cutting machines available in the market and therefore, they all carry different price tags. Let us discuss some of the common tube laser cutting machine prices

so that you can make a buying decision based on your needs and budget.

Fiber laser pipe cutting machine principle.

Fiber laser pipe cutting machine is a pump material mixed into the fiber, and come to fiber laser pipe cutting machine of a specific wavelength of laser scourge after the combination, so that the fiber to produce laser light, focused on the surface of the workpiece, the irradiation of the workpiece on the spot of the area local instantaneous is a set of laser technology, CNC technology, mechanical technology as one of the high-tech equipment.

Fiber laser pipe cutting machine processing materials.

Industrial pipe cutting machine Can be a variety of metal plates, tubes, mainly stainless steel, carbon steel, alloy steel, silicon steel, spring steel, aluminum, magnesium and aluminum alloy, galvanized plate, aluminum-plated version, pickled plate, copper, silver, gold, titanium

Fiber tube laser cutting machine is applicable to

Metal sheet processing, advertising sign word production, high and low voltage electronic equipment shell production, mechanical parts, kitchenware, automotive, machinery, metal crafts, saw blades, electrical parts, glasses industry, spring pieces, circuit boards, electric kettles, medical microelectronics, hardware, etc.

Features of tube laser cutting machine

Pipe laser cutting machine will generally be paired with automatic loading and unloading devices, which can reduce the manual handling, significantly reducing the cost of investment. Small laser pipe cutting machine using the Park Chu CNC system, you can cut at will, no matter what kind of graphics, the use of CAD mapping can be completed, reducing the investment in labor costs, cutting 0 tail material, cutting surface smooth, no burrs do not need to manually polish again.

Automatic tube laser cutting machine makes tube processing easier and more relaxed, enhancing the efficiency of manufacturing production and improving the quality of products. Automatic tube cutting machine is not limited to pattern design limited, automated layout to save raw materials, smooth trauma, processing low cost.

Laser pipe cutting machine cutting copper pipe attention

Laser pipe cutting machine in cutting copper pipe, punching and cutting copper must use high pressure oxygen to enhance the technical stability of the process. But for copper, actually N2 is very good, the cutting effect is also will be better. Round tube laser cutting machine laser generator can reduce the time of the raw material in the case of reflective surface also, to enhance the speed of hole-breaking and cutting high efficiency.

Tube laser pipe cutting machine in cutting copper pipe when the focus of the part is also particularly important, should be set close to the top, which makes the process gradually when and light mutual influence on the surface raw materials at least, thus making the power of light greater, so that the raw materials quickly dissolved. Pipe cutting tail rudder material is shorter, more aspects of the upper side of the savings in raw material costs.

Automatic laser tube cutting machine cooling circulating water replacement and small water tank clear to be in the laser cutting equipment to carry out work in the former must do things. Circulating system water quality and ambient temperature is directly related to the use of laser diode period, this work is generally carried out once a week.

Thick steel plate cutting machine when the exhaust system is not open to the centrifugal fan must be clean, to clean the metal laser cutting machine equipment glasses lens daily, clean up the time to pay attention to gently scrub, not to destroy the surface, clean the course to be careful and lightly placed to avoid bursting, laser cutting equipment assembly focus camera lens must let the groove down.

Large and medium-sized cutting confidential documents every two weeks to clean up the slide, clean up before you should turn off the fiber optic wire cutting machine. Laser marking machine after a period of time to re-plan the CNC lathe level to ensure that the CNC lathe cutting elimination precision. In carrying out the cutting board before the time must be timely treatment of the bed to prevent impurities into the slide rail, increasing the service life of the laser cutting machine slide rail.

Advantages of tube laser pipe cutting machine

Metal pipe laser cutting machine can not only replace the machinery and equipment in the hole, milling, cutting, stamping parts processing and other process operations, but also for round steel pipe, square pipe, slotted pipe can be directly cut open hole. Automatic laser pipe cutting machine can not hurt the raw material, the pipe to carry out no burr cutting, cutting high precision, laser cutting heat hazard is small, cutting the basic no deformation, cross-sectional no air oxidation condition is more suitable for mass production of pipe processing.

Automatic laser pipe cutting machine is generally equipped with automatic feeding equipment, a full set of laser cutting machine equipment to a huge extent to reduce the handling of loading and unloading, reducing the cost of capital investment. At the same time, the laser pipe cutting machine is used to control the system, can produce and process some long elaborate pattern design, also can carry out cutting in all directions.

The standard length of the round pipe laser cutting machine is 6 meters, the choice of hydraulic chuck can easily carry out the clamping of the round steel pipe to carry out mass production processing of the actual operation.

Laser pipe cutting machine in cutting small diameter pipe, the slag is very easy to rely on the inner cavity of the tube. Most of the heat caused by cutting is absorbed by the product digestion, cutting the relatively large density will lead to pipe superheat, very serious will affect the quality of round steel pipe incision. This time round pipe laser cutting machine can increase the oxygen way to enhance the generation rate, to ensure that the cutting nozzle and laser cutting machine focus to maintain a continuous situation, to promote the actual effect of cutting does not follow the workpiece surface changes caused by the impact.

Laser pipe cutting machine has a very high reliability, the laser generator used by the Chuangxin, compact structure, small size, low kinetic energy loss cutting performance is stable. Laser pipe cutting machine uses cutting-edge hydraulic chuck clamping system software, hydraulic chuck self-regulating core, laser pipe cutting machine according to the profile specifications fully automatic adjustment of the clamping force size to ensure high quality of thin pipe clamping. Tube laser pipe cutting machine cutting high precision, cost-effective very high.

Laser pipe cutting machine purchase machine attention

Matters a: bed selection

Q: What is the impact of the bed for the pipe cutting machine? How to choose?

A: In addition to considering the load, the bed of the pipe cutting machine needs to consider whether the structural design can meet the task requirements, because it directly affects the load capacity and cutting accuracy. A twisted and deformed bed seriously affects the accuracy and service life of the equipment. Therefore, the bed is good or bad and structural design is more related to the excellent structural design can ensure that the bed can achieve the ideal cutting effect even under a large load.

Matter two: tail material control

Q: How to achieve the ideal effect of pipe cutting for tail material control?

A: Zero tail material and very short tail material is the ideal effect pursued by the processing industry. At present, only three chucks or four chucks pipe cutting machine can achieve zero tail material cutting, the tail material below 80 mm is called very short tail material, is the function of two chucks, to achieve this function also has restrictions, such as: there is a suitable length of the workpiece in the pipe full of cloth; use very short tail material cutting the last workpiece accuracy requirements are not high.

Matter three: processing capacity

Q: How to determine the processing capacity of the equipment?

A: The processing capacity of the equipment can be examined from the processing pipe diameter, processing wall thickness, processing length of these aspects. The size of the chuck to determine the size of the pipe cutting machine cutting pipe diameter, you can first see whether the size of the chuck to meet production needs, fiber laser can cut all kinds of metals and various profiles, there is no special restrictions. To judge the effective processing length of the pipe and processing thickness, it is necessary to refer to the technical program, or consult the technical staff. In fact, the direct and effective way to judge the processing capacity is to sample test.

Matter four: the configuration of accessories

Q: the importance of laser tube cutting machine accessories configuration? Which accessories system can be the main concern?

A: Accessories configuration for the performance of the machine has a very important impact, high-quality accessories system can be supported for the processing capacity of the pipe cutting machine plus a lot of points. In general, you can focus on the chuck, guide rail, rack, screw, motor, cable, air circuit, etc.. Especially recommended to understand the quality control process of equipment manufacturers, good quality control process can make ordinary accessories play a higher performance.

Matter 5: Sample quality

Q: samples are not cut well on behalf of the equipment does not work?

A: You can not make such a judgment. In the laser cutting capacity range, do not have to consider the quality of the section. If the section quality is poor, you can adjust the cutting process. If you can not adjust to a satisfactory state, you can contact the manufacturer after-sales service.

How to choose the right fiber laser pipe cutting machine

Laser tube cutting machine for many industries is a necessary piece of equipment, but many people do not know how to pick the right Laser tube cutter, China laser pipe cutting machine factory simply share.

- from a personal point of view, cnc laser tube cutting machine for sale price is an important choice, do not try to use the market tube laser cutting machine price to buy the same or even better pipe laser cutting machine, we have to be based on the actual We have to buy the more appropriate laser tube cutting machine according to the actual situation.

- Do not buy all-in-one machine at once, from some aspects of the words, personal operation is more difficult, after all, the greater the function of the operation is more complex, so the purchase to buy a cnc fiber tube cutter laser to meet the current industry use on it.

- If you speak from the perspective of tube laser cutting machine factory, to fully analyze whether to find manufacturers direct sales or distributors, whether you need to visit the site and then buy laser pipe cutting machine.