laser tube cutting machine for sale

- 首页

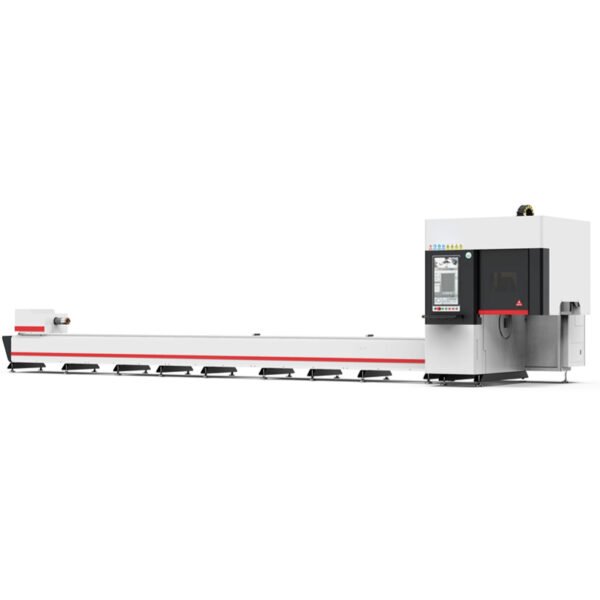

- Laser Tube Cutting Machine for Sale

1kw 1500w 2000w 3kw laser tube cutting machine for sale

Model: 1000W 1500W 2000W 3000w

Category: laser tube cutting machines

Sale Price: $3,0000.00 / Set

Supply Abilit: 50 Sets / Month In stock!

Payment Terms : T/T/Visa/Mastercard/American Express/Discover cards

After-sale Service : Free professional machine operation training.

Are you looking for affordable fiber laser pipe cutting machine (metal laser pipe cutting machine,) for stainless steel pipe, channel steel, angle steel and other metal pipe cutting, power 1000W, 1500W, 2000W, 3000W, 4000W, 6000W, 8000W, 10000W, 12000W, 15000W, 20000W, 30000W It is mainly used for cutting products such as molds, advertising letters, kitchenware, doors and windows, industrial equipment, advertising industry, machinery production, agricultural machinery, elevators, aircraft, shipbuilding, etc.

Introduction of CNC laser tube cutting machine

Laser tube cutting machine is also known as pipe laser cutting machine, metal laser tube cutting equipment, CNC tube laser cutting machine, which can cut round tubes, square tubes, special-shaped tubes, H steel, angle steel and other metal tubes.

Laser tube cutting machine is a high-tech product integrating laser cutting, precision machinery, numerical control technology and other disciplines.

It is mainly used for cutting carbon steel pipes, stainless steel pipes, aluminum alloy pipes (square pipes, round pipes, waist round pipes) and other metal pipes. It has the characteristics of professionalism, high speed, high precision, high efficiency and high cost performance. The preferred cutting model.

CNC fiber laser tube cutting machine video

Metal laser tube cutting machine Parameters

Model | Tube Fiber Laser Cutting Machine |

Laser Power | 1000W/1500W/2000W/3000W/4000W/6000W |

Pipe Processing Range | 6000mm* φ15~220mm |

Maximum Speed | 100m/min |

Maximum Rotational Speed | 100r/min |

Z-axis Travel | 220mm |

Positioning Accuracy | ±0.05mm |

Repeated Positioning | ±0.02mm |

Maximum Acceleration | 0.8G |

Angle of Processing Bevel | ±45° |

Table Maximum Load(KG) | 150 |

Outline Size(mm) | 9000*2900 *2400 |

Power Parameters | Three-phase AC 380V 50Hz |

Protection Level of Total Power Supply | IP54 |

Metal laser tube cutting machine configuration

1, fiber laser

To discuss which is the core component of the laser cutting machine, fiber laser is certainly the first, fiber laser is the core power source of the laser cutting machine, can directly affect the performance of the equipment, thus affecting the overall cutting operation. At present, the domestic fiber laser is increasingly mature and stable, gradually replacing the imported laser market, such as China’s fiber laser manufacturers Rike Laser, Chuangxin Laser, etc. are its excellent representatives, which also to a certain extent promote the development of China’s laser cutting machine.

2, laser cutting head

laser cutting head as a device to output laser, is composed of focus tracking system, focusing lens and nozzle, generally in cutting different shapes, thickness of metal pipe, there are corresponding specifications, the operator to debug and adjust it accordingly;.

3、Motor

Motors are generally divided into two kinds, stepper motors and servo motors, although they are motors, but these two motors have control accuracy, moment frequency characteristics, operating performance, speed response performance, low-frequency characteristics and other aspects of the difference. Stepper motor starting speed, responsive, more suitable for less demanding cutting, engraving processing, and the price is not high, servo motor has many advantages, including: fast movement, high load, stable performance, etc., but its price is generally higher, suitable for use in industries with high processing requirements, is also widely used in the laser cutting machine industry, pipe laser cutting machine is also used servo motor.

Of course, in addition to these, there are machine tools, laser lenses, control systems, etc., are more important parts of the pipe laser cutting machine equipment, it is because of these parts, to achieve such an excellent laser cutting machine, and in the field of plate cutting.

Tube laser cutting machine processing characteristics.

1. Cutting a wide range of pipe types, capable of cutting, punching, wall hollowing and engraving as well as bevel beveling and other three-dimensional processing of round, square and flat pipe materials.

2. Laser processing speed, high cutting accuracy, to achieve efficient processing of large quantities.

3. Simple operation; adopt CNC operation platform, input the corresponding drawings to realize fast processing, flexible and quick.

Advantages of laser tube cutting equipment:

1. Diverse cutting, fast/accurate/ruthless pipe cutting, easy to cut pipes of various shapes, the incision is flat and smooth without burrs

2. Full-stroke pneumatic chuck: automatic centering, reducing the waiting time for loading and unloading materials, and improving production efficiency. Pneumatic open clamp, the thick tube of the large tube is not loose and does not slip.

3. Optional semi/automatic feeding: customized on demand, users can choose semi-automatic feeding or fully automatic feeding function according to production needs.

4. The CNC control system can be deeply developed according to the cutting needs of different users.

How to reduce the cost of laser pipe cutting machine?

CNC metal laser pipe cutting machine is a professional metal pipe cutting equipment. We need to choose the appropriate model according to the actual situation of the enterprise. For example, the power cannot be used too large or too small, because too much power will burn out the pipe. , too small will cause cutting. Therefore, when choosing these CNC laser pipe cutting machines, we must choose a formal laser pipe cutting machine manufacturer and choose a formal product.

Secondly, we use the fiber laser pipe cutting machine, and we cannot start it frequently, because frequent startup will reduce the working efficiency of the machine and the equipment will also be lost. It is recommended that enterprises plan the cutting time reasonably and complete the cutting task as soon as possible.

Then we should also optimize the quality of pipe cutting, have good pipe cutting equipment, trained operators, cut higher quality workpieces, reduce waste and cost of secondary processing.

1. The laser pipe cutting machine is suitable for cutting pipes of various materials;

2. The cutting speed is fast, no burr, and the cutting port is perpendicular to the pipe;

3. The clamping jaw made of stainless steel is composed of a self-centering clamping system with a wide diameter;

4. The cutting blade of the automatic pipe cutting machine is very close to the clamping system, which can avoid pipe vibration, even if cutting thin-walled pipes or small-diameter pipes to ensure no deformation;

5. The structure of the pipe cutting machine is compact and easy to carry, which is very suitable for on-site installation or workshop operations;

6. The setting is simple and quick;

7. Optional pneumatic or electric cutting motor;

8. The laser pipe cutting machine only needs to add an automatic electric rotation control system and a welding power source to realize the all-position welding function. The required power source for the welder can carry out the required welding process.

Stainless steel tube laser cutting machine Application industries

Petroleum sieve tube.

Tube laser cutting machine processing oil sieve tube accuracy: sieve tube wall thickness ≤ 20mm, seam width ≥ 0.15mm, seam cross-section rectangular, trapezoidal and various shaped holes, the type of cloth seam including parallel, staggered, spiral, etc., hole center distance error of 0.01-0.02 mm, density laser beam positioning accuracy of ± 0.03mm, repeat accuracy of ± 0.01mm, surface cutting finish of 6.3.

Car exhaust pipe

As a high-grade consumer goods, in order to enhance the value of the product, the product production process is the main breakthrough point. Tube laser cutting machine processing car exhaust pipe without burr, internal pipe wall smooth, fast processing speed, is a good choice for batch processing.

Lighting fixtures

The style of metal lamps and lanterns outer cover is common for hollow carved style mostly, or even more complex patterns. Tube laser cutting machine processing lamps and lanterns cover high efficiency, clear patterns do not deform, and no secondary processing, greatly reducing production costs.

At present, laser pipe cutting machines are widely used, and many industries need to help hardware furniture, auto parts industry, stainless steel product industry, bathroom building materials, sports equipment, anti-theft nets and other industries to achieve high production efficiency, improve production quality, and reduce production costs. The reason why more and more businesses choose.

If you want to know more about the laser pipe cutting machine, leave a message in the comment area, and the editor will send it in time.