Metal exposed to the air will rust, many products because of rust leads to the use of trouble, so the handheld laser cleaning machine came into being.Laser rust removal machine cleaning technology is environmentally friendly and efficient, safe and reliable, and does not harm the health of the operator. fiber laser cleaning machine can remove a variety of different thicknesses, different components of the coating, cleaning process is easy to achieve automatic control, to achieve remote control of remote cleaning, etc..

High power clean laser machine to reduce the use of cost to improve efficiency, mobile laser cleaning machine efficient, fast, low cost, the heat load and mechanical load generated on the substrate is small, cleaning for non-damage, waste can be recycled, no environmental pollution.

Laser cleaning principle

Due to the laser cleaning substances, process characteristics and the wavelength of the laser used, energy density and cleaning methods differ, the mechanism of laser cleaning also differs. The use of laser has high intensity, high energy density, focusing, directional characteristics, through the lens combination can focus the beam, the beam is concentrated into a very small area.

Future market prospects for laser cleaning

The advantages of laser cleaning in paint removal have been proven in the market (including high-speed rail, subway wheel pair paint removal, aircraft skin paint removal, etc.), but the shipbuilding industry to remove the thick paint on the surface of the hull is still using sandblasting process. Although the efficiency of laser paint removal has been greatly improved by improving the process and increasing the power, the efficiency is still too low for the demand of paint removal on tens of thousands of square meters of a ship. The reason for this has a lot to do with the insufficient power of the laser.

Before the market popularization of laser cleaning equipment are mostly handheld, requiring manual operation of workers, more flexible in the cleaning of small molds, but in the face of aerospace, ships and large infrastructure areas of cleaning, it is inefficient.

When the laser cleaning as pre-welding and post-welding process, the use of handheld equipment cleaning and then transported to transfer, wasted time and manpower. Therefore, laser cleaning is bound to also towards automation, intelligent development, by combining with other manufacturing equipment to achieve a production line to solve all the problems of a product.

The high cost of laser cleaning equipment is the key to limit the popularity of laser cleaning applications. Although the marking and cutting market has experienced a price war, the price of the product has dropped again and again, but the equipment has been popularized: more and more users accept the laser equipment, and the laser instead of the traditional process. The laser cleaning market is still in the blue ocean period, still need to further reduce prices to improve market acceptance

Laser cleaning application

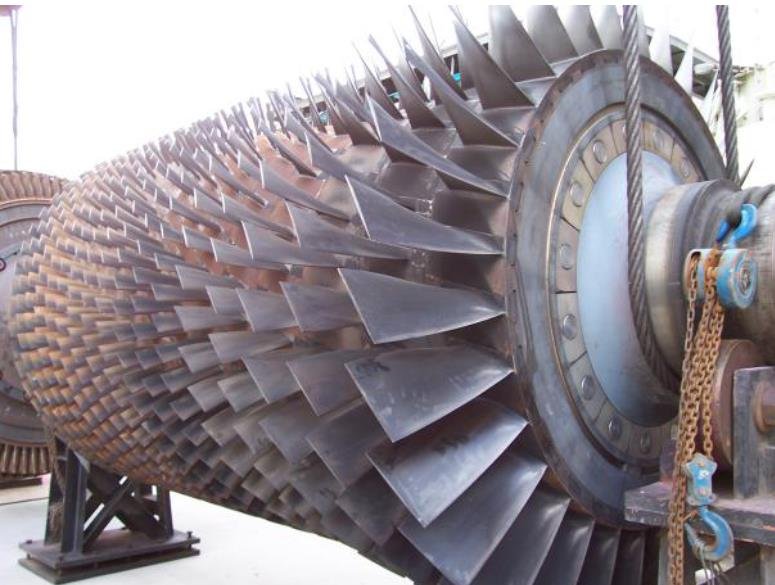

Hand-held laser cleaning machine for rust removal has a wide range of application prospects, in aerospace, shipbuilding, rail transportation, automotive manufacturing, steel manufacturing and other aspects have been well used.

The portable rust removal fiber laser cleaning machine is easy to remove rust, paint, grease, coatings, 3 minutes to get started easy to remove dirt without asking for help. industrial laser cleaning machine is self-developed, ergonomic design, lightweight and easy to use, long hold not tired focal length 550 -600mm, cleaning width up to 160 +10mm short focal length, wide range, high tolerance, small light failure operation flexibility, convenient in large irregular workpiece cleaning.

4 advantages of removing oil stains from copper pipe surfaces

1、laser rust removal not only can be handheld cleaning, but also can be used with robots or sliding tables, work equipment, to achieve automated cleaning.

2、No waste generation, reduce the amount of waste, no pollution to the environment.

3、Simple operation, plug in the electricity can be used, handheld lightweight and easy to operate.

4, laser rust removal method is non-abrasive and non-contact, will not cause damage to the material.

How to choose the right laser cleaning machine manufacturers

Currently, fiber laser cleaning machine is becoming more and more popular in the industrial market, and more and more industries are using it. For that, different configurations correspond to different effects, and naturally the price of industrial laser cleaning machine is also different. However, among the many laser cleaning machine manufacturers, is the more expensive the more appropriate? The answer is no. So how to buy the right clean laser machine?

Confirmation of product suitability for laser metal cleaner

In the choice of laser cleaning machine, you need to confirm whether your product is suitable for laser cleaning technology. Nowadays, most laser cleaning equipment manufacturers offer free prototype service. You can tell the supplier the material you need to clean, and let them take a video of the cleaning process to confirm the cleaning effect.

Handheld laser cleaner price

Before you buy laser cleaner, you should know your welding needs. To ensure that the laser cleaner can achieve the workshop processing effect and bring benefits to the store, such cleaning equipment is what the store needs.

The price of laser descaling equipment varies, but also specifically with the power and model, the model and power are different, the performance and price of the equipment is also different, its price ranges from $8,000 – $50,000, the specific price or depends on the selection of equipment.

For laser cleaner manufacturers, laser cleaner cost has expensive and cheap. High-end cleaning equipment can make the processing effect more comprehensive, cleaning effect is better, but the price of this equipment is also more expensive. If your workshop does not require high processing effect, it is recommended to choose the general performance, which can meet the metal cleaning needs of the workshop and save the budget of purchasing equipment.

The choice of laser cleaning machine power

The laser generator is the core of the laser equipment. Generally speaking, the higher the power of the laser cleaner, the deeper the cleaning depth, the higher the price.

But it should be noted that if it is penetrating can choose 1000w laser cleaner; if it is continuous cleaning, it is best to use a higher power laser. Choose 1500W or 2000W laser cleaner is more appropriate.

Handheld laser rust remover parameters

| Item | Data |

| Power | 1500W, 1000W, 2000W |

| Applicable Material | Stainless Steel, Carbon steel, Aluminum, Metal |

| Core Components | Motor |

| Laser Type | Fiber Laser |

| Dimension(L*W*H) | 900mm*450mm*950mm |

| Key Selling Points | Multifunctional |

| Weight (KG) | MAX |

| Warranty | 3 Years |

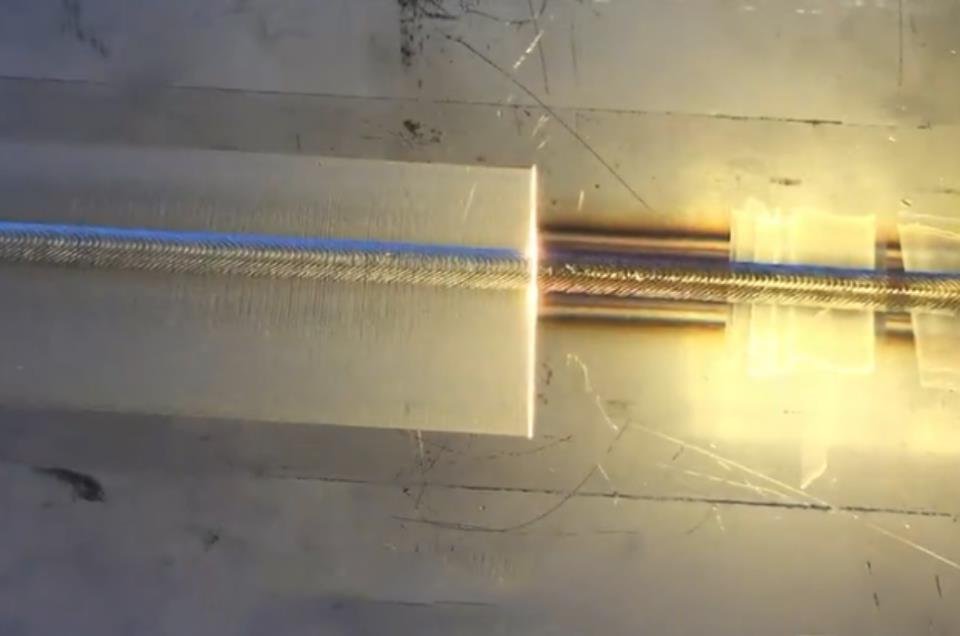

Application advantages on weld cleaning.

1、Precise cleaning, can achieve precise location, precise size selective cleaning.

2, without any chemical cleaning solution, no consumables, safe and environmentally friendly.

3, simple operation, power can be, handheld or with the robot to achieve automated cleaning.

4, cleaning efficiency is very high, saving time.

5、Laser cleaning system is stable, almost no maintenance.

Laser cleaning equipment can not only clean the weld seam after welding, but also remove rust, oil, paint and other dirt from the metal surface.

Metal surface treatment before and after welding

Welding cleaning is divided into electric welding before the surface oxide layer cleaning and electric welding after the surface welding color cleaning, general metal products electric welding welding materials are aluminum alloy profiles and stainless steel plate, the material is not the same, the efficiency and quality of cleaning is also different.

Continuous laser cleaning machine effect is good? Under normal circumstances, the same output power machine equipment aluminum alloy material efficiency is slightly higher, and stainless steel material effect is also a little deeper than aluminum alloy material cleaning level, naturally also depends specifically on the cleaning requirements. Can do high quality, but also can do too much cleaning.

Advantages of laser cleaning

Laser cleaning machine for rust removal technical level to achieve non-contact, more accurate and clean, can be remotely controlled, selective removal, to achieve semi-automatic or fully automatic unmanned workshop.

Unit cost, energy consumption, efficiency and other aspects are better than other cleaning methods. The environment can be industrial level zero pollution.

Disadvantages of laser cleaning machine

The development of handheld laser cleaning machine for rust removal is not fast enough. At present has not been able to cover the full range of industrial cleaning, a wide range of industrial applications are basically concentrated in the mold, metal materials and other mid-range market.

In the application of manual grinding, angle grinder, wire brush, scraper to remove paint and rust in some low-end market, laser cleaning machine volume seems too large

Hand held laser rust remover in the high-end cleaning market, such as ship overhaul paint removal work, although many shipyards proposed to use laser cleaning, but the current laser surface cleaner in efficiency than chemical cleaning, high-pressure water cleaning and other traditional methods, but still can not meet the requirements of shipyards.

Selecting the right power level for laser cleaning machines

Low Power Laser Cleaners

Low power does not equal low efficiency. Low-power laser cleaning solutions provide gentle, high-precision cleaning. He is used together with other electric cleaners with short pulse lasers of the same cleaning intensity. This low power laser cleaner is ideally suited for the following products.

- Restoration of historical artifacts

- Precious artwork

- Precision instruments

- Rubber/injection molds

- Any product that requires gentle cleaning

Medium Power Laser Cleaners

- Removing metal oxides or lubricants prior to welding

- Surface metal descaling of machinery and equipment

- Surface rust removal from steel rails

- Composite materials and tire molds

- Paint removal on aircraft

High Power Laser Cleaners

The high power laser cleaner generates large amounts of energy and is ideal for industrial use.

- Severe metal corrosion

- Removal of harmful coatings

- Pre-treatment of weld seams

High cleaning efficiency without damaging the substrate

The cleaning technology of hand-held rust remover is environmentally friendly and efficient, safe and reliable, and does not harm the health of the operator. Metal cleaning machine can remove all kinds of coatings of different thickness and composition, and the cleaning process is easy to realize automatic control and realize remote control cleaning from a distance, etc.

High power laser cleaning machine to reduce the cost of use to improve efficiency, mobile laser cleaning machine is efficient, fast, low cost, the heat load and mechanical load generated on the substrate is small, cleaning for non-damage, waste can be recycled, no environmental pollution.

Portable rust removal and rust remover has a wide range of application prospects, and has been well used in aerospace, shipbuilding, rail transportation, automobile manufacturing, steel manufacturing, etc.

Multifunctional carbon steel and aluminum alloy sheet metal rust removal metal laser cleaning machine easy to remove rust, paint, oil, coating, 3 minutes to get started easy to decontaminate without asking.

Decontamination and rust removal machine laser rust removal machine is independent research and development, ergonomic design, lightweight and easy to use, long hold not tired focal length 550-600mm, cleaning width up to 160 +10mm short focal length, wide range, high tolerance, small light failure operation flexibility, convenient in large irregular workpiece cleaning.

Laser cleaning machine import customs clearance procedures

Laser cleaning traditional cleaning industry has a variety of cleaning methods, laser cleaning has no abrasive, non-contact, non-thermal effect and applicable to a variety of materials and other cleaning characteristics, is considered the most reliable, the most effective solution

I believe that many people do not know about laser cleaning machine import customs clearance procedures and processes and other issues, the next, for you to introduce the details of the laser cleaning machine import customs those things!

Take a look at import customs clearance procedures information

Function/use, packing list, contract, bill of lading, invoice, inspection and customs declaration letter of attorney, import and export authority, customs clearance of inbound goods, GTIN, Chinese or foreign language name, inspection and customs declaration letter of attorney, consignee or consignor record number, output power, etc.

Talk about import customs clearance process

- Prepare laser cleaning machine import customs declaration clearance information

- Laser cleaning machine arrived at the port or airport for the exchange of orders

- Import inspection / customs declaration / price declaration of laser cleaning machine

- Check the laser cleaning machine, check the goods

- Laser cleaning machine out of the tax bill

- Pay laser cleaning machine import taxes

- Release the goods / pick up the goods

- Delivery to the designated domestic location

Import of laser cleaning machine frequently asked questions

- How long does it take to import the entire laser cleaning machine?

- If the importing enterprise does not have the right to import and export business can import laser cleaning machine?

- laser cleaning machine import duties and VAT are how much?

- What are the costs of importing laser cleaners? How to calculate the cost?

- Imported laser cleaning machine arrived at the port (airport) to how to pick up the goods?

- At present, the general import of laser cleaning machine has those kinds of ways?

- can not enjoy tariff preferences?

- the import of laser cleaning machine is there access restrictions? Laser cleaning machine import access to the list of countries?

- laser cleaning machine imports need to pay attention to what matters?