The rapid development of the industrial market, metal laser pipe cutting machine as well as three-dimensional laser plate cutting machine has been introduced one after another.

The new process has greatly improved the production time for bevel cutting of pipe fittings and sheet metal, and has been used in a large number of industries such as agricultural machinery, automobile manufacturing, and metal pipe processing.

In the pipe processing process, metal laser cutting machine can complete all types of pipe processing at high speed, and high cutting accuracy, speed, efficiency is much higher than the traditional metal cutting, nowadays has been widely recognized by various industries.

What is a tube laser cutting machine?

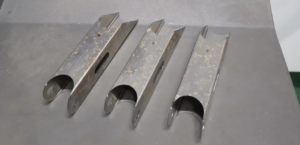

The laser pipe cutting machine can cut the pipe at any angle and arc, and the cutting accuracy, kerf effect, cutting efficiency will be higher and the cut out products will be better.

Tube laser cutting machine features:

Pipe laser cutting machine in the laser cutting, the heat impact is small, the cut pipe almost no thermal deformation, no oxidation in the section.

Automatic laser pipe cutting machine for small tubes can also do precision cutting, and no damage to the raw material, cutting no burr, the cut surface is flat.

Laser pipe cutting machine has high efficiency, can work for a long time, suitable for processing a large number of pipes, reduce the investment of labor costs, improve the input-output ratio of enterprises, so that enterprises can make profits in a short period of time.

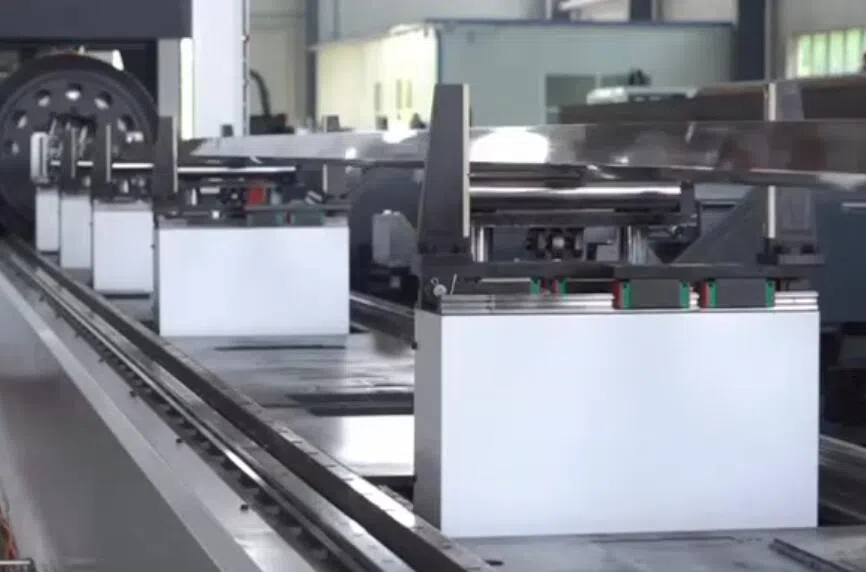

Pipe laser cutting machine will generally be paired with automatic loading and unloading devices, which can reduce the manual handling, significantly reducing the cost of investment.

Small laser pipe cutting machine using the Park Chu CNC system, you can cut at will, no matter what kind of graphics, the use of CAD mapping can be completed, reducing the investment in labor costs, cutting 0 tail material, cutting surface smooth, no burrs do not need to manually polish again.

Automatic tube laser cutting machine makes tube processing easier and more relaxed, enhancing the efficiency of manufacturing production and improving the quality of products. Automatic tube cutting machine is not limited to pattern design limited, automated layout to save raw materials, smooth trauma, processing low cost.

How to choose an affordable metal laser pipe cutting machine price.

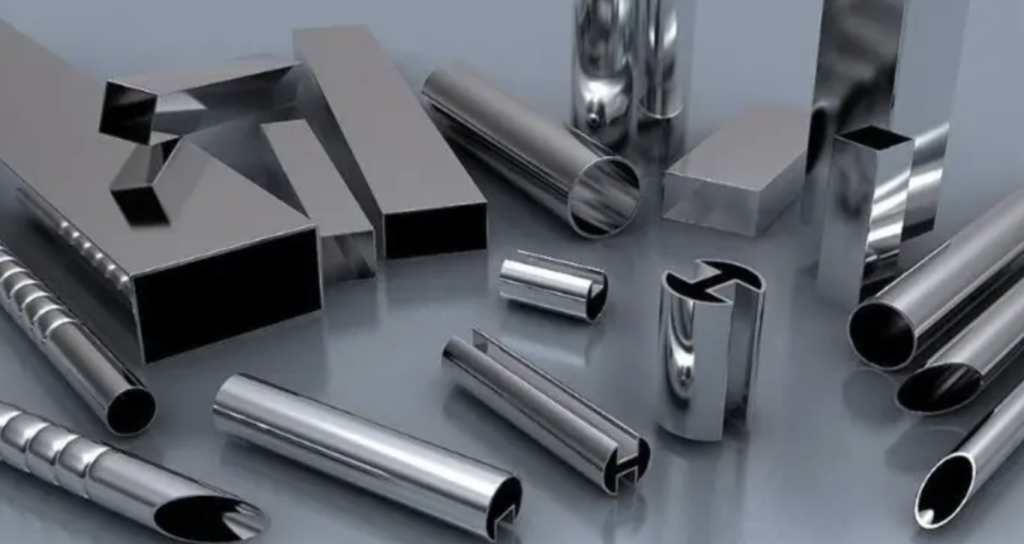

Laser pipe cutting machine is the main equipment for pipe cutting, in the use of whether it is square, round, or shaped pipe, can be effectively cut in cutting pipe than other equipment more advantageous, pipe laser cutting machine with its professional, stable cutting effect quickly occupied the various metal processing industry, especially in automotive manufacturing, oil mining, machinery manufacturing, etc. get a lot of applications.

One of the biggest benefits of using a laser tube cutter is that it can make complex cuts much faster than other machines. For example, it can punch holes and cut various shapes and sizes of tubes. In addition, laser tube cutting provides good cut sections for subsequent processing such as welding without the need for secondary processing, which is equally applicable in both thin and thick walled tube cutting. What really sets laser tube cutting apart is the accuracy of the cut, and industrial manufacturing applications involving small diameter tubes have been greatly accelerated by improvements in modern laser cutting machines.

Compared to traditional tube processing methods, laser cutting of tubes has numerous advantages such as saving time, time and money. In the long run, high value conversion at low cost can be easily achieved for business development. Therefore, with the task of batch pipe cutting, it is crucial to purchase a super cost-effective production tool.

Can you get a professional laser tube cutter for $30,000?

The answer is: Of course!!! Yes you can!!!

The configuration of the pipe laser cutting machine.

Fitted with special precision chuck – high precision cutting

Fully enclosed structure with tight dustproof function, stain and dirt resistant, stable and wear-resistant; internal parts with heat treatment and grinding process, long chuck life.

One key to open the chuck, intelligent centering, convenient and fast, greatly improve the cutting efficiency; one key to clamping, clamping accuracy is high and durable; clamping force can be adjusted according to the weight of the pipe, stable and reliable.

The maximum speed of the chuck reaches 100r/min, clamping accuracy (clamping concentricity) <0.1mm, acceleration 1.0G.

Equipped with high quality accessories-simplicity is not simple

Reduced diameter wheel support, wide range of applicable pipe diameter, no need to change support, high quality drag chain cable bending resistance, no breakage, air pipe joint with its own seal ring, reduce the probability of impurities into the air path, professional industrial control machine anti-high temperature design, to protect the performance of full load work.

Intelligent and easy to upgrade – to meet diverse needs

Design, the design of the downcomer slot can be expanded according to the needs of pipe fittings, pipe cutting machine part without special design, optional or additional automatic loading and unloading system, easy to upgrade, fully meet the needs of efficient and intelligent processing.

Laser tube cutting technology is in the process of rapid development and continuous improvement, with the computer technology, mechanical structure, cutting technology and optimization algorithm of continuous updating and development, CNC laser tube cutting technology will be more prominent to show its intelligent, fast and optimized cutting process and skills, for the laser tube cutting machine of efficient cutting, high quality cutting, as well as saving pipe and energy consumption, to provide technical assurance.

6 advantages of pipe laser cutting machine.

As we all know, the so-called laser cutting is to use the focusing mirror to focus the laser beam on the surface of the material, so that the material melted, while using the compressed gas coaxial with the laser beam to blow away the melted material, and the laser beam and the material along a certain trajectory for relative motion, so as to form a certain shape of the cut. At present, the laser cutting technology of Shenzhen Junyi Laser has been widely used in many fields. We will briefly analyze the advantages of laser cutting for you.

1: High precision.

The high accuracy of laser cutting compared to traditional cutting technology is self-evident. Usually, the positioning accuracy of laser cutting is 0.05 mm, repeat positioning accuracy is 0.02 mm, suitable for precision parts cutting and various processes of fine cutting.

2: Narrow cutting slit.

The laser beam is focused into a very small spot so that a high power density is reached at the focal point and the material is quickly heated to the degree of vaporization and evaporation to form a hole. With the relative linear movement of the beam and the material, the hole is continuously formed into a very narrow width of the cut. The kerf width is generally 0.10-0.20mm, which is very narrow compared to the traditional cutting technology, and will not affect the aesthetics of the workpiece.

3: the cutting surface is smooth.

Many workpieces have high technical requirements and do not allow any burrs, so traditional cutting technology is difficult to meet the requirements, while SHINE laser cutting technology can achieve a smooth and beautiful cut without burrs, which is loved by our customers.

4: Fast speed.

Under normal circumstances, the laser cutting speed can reach 10m/min and the maximum positioning speed can reach 70m/min, which is much faster than the speed of wire cutting. This is very important for industrial production, can greatly save time to improve efficiency and save costs.

5: good cutting quality, no damage.

From the principle and definition of laser cutting can be known, laser cutting belongs to the contactless cutting, cutting edge is very little affected by heat, basically no thermal deformation of the workpiece, completely avoid the collapse of the edge formed when the material punching and shearing, the cut generally does not require secondary processing. Laser cutting head will not contact with the surface of the material, not scratch the workpiece.

6: Wide material applicability

Shine laser can not only process steel plate, stainless steel, aluminum alloy plate, carbide and other plates, but also cut a variety of tubes, round tubes, square tubes, shaped tubes, I-beam, channel steel, etc., good flexibility, can process any graphics, a variety of power, 10,000 watts of power technology is far beyond the peer.