Carbon Steel Laser Cutting Machine Suppliers & Wholesalers

SUNSHAN has been providing top-notch carbon steel laser cutting machine manufacturing services for over 10 years. From design, prototyping, metal box folding to welding, we can do it all. More than 10 years of service. From design, prototyping, metal box folding to welding, we can do it all.

Custom Carbon Steel Laser Cutting Machine and Custom Metal Laser Cutting Machine

SUNSHAN provides complete Carbon Steel Laser Cutting Machine manufacturing services. Our business includes laser cutting machine, laser welding machine, laser cleaning machine.

Carbon steel sheet laser cutting machines are useful in many industries. Such as electronics, automobiles and agricultural machinery. Also, SHINE can OEM ODM laser cutting machine according to customer’s needs to meet your specifications. Whatever your application, we have the best laser cutter for its manufacture. Customize a fiber laser cutter to meet your needs. Whatever your application, we can provide you with the cheapest metal fiber laser cutting machines price.

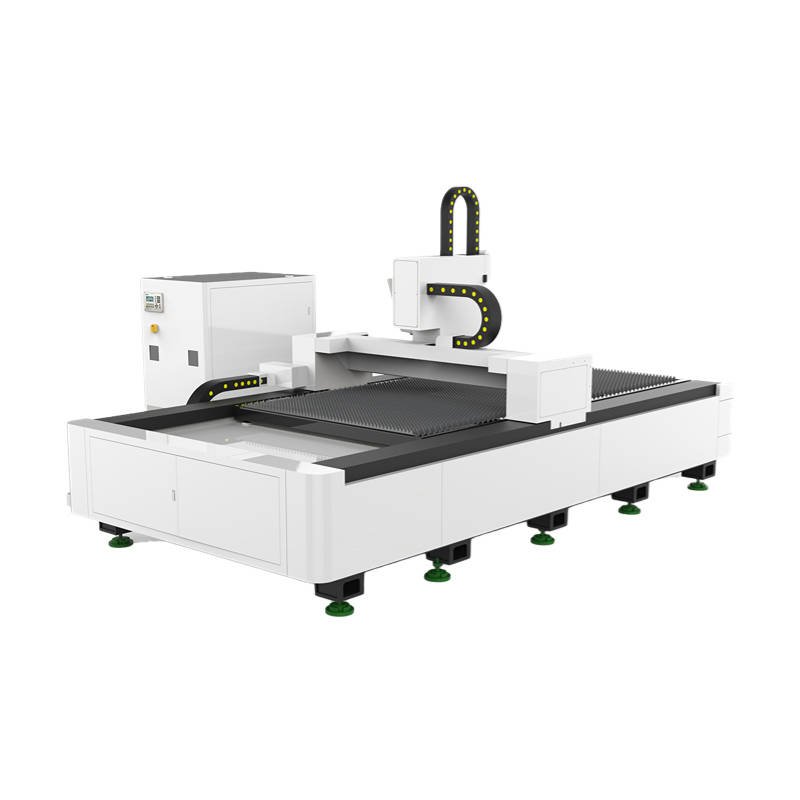

Metal Laser Cutter For Sale

Parameter of Laser Cutting Machine for Steel

| Model | 3015G/4015G/4020G/6015G/6020G metal laser cutting machine |

| Working Area | 3050*1525/4050*1525/4050*2020/6050*1525/6050*2020 |

| Laser Power(kw) | 1.5/2/3/4 |

| Maximum Speed(m/min) | 80 |

| Maximum acceleration(g) | 0.8 |

| X/Y Axis positioning accuracy(mm/m) | ±0.05 |

| X/Y Axis repeated positioning accuracy(mm) | ± 0.02 |

Metal laser cutting machine cutting products

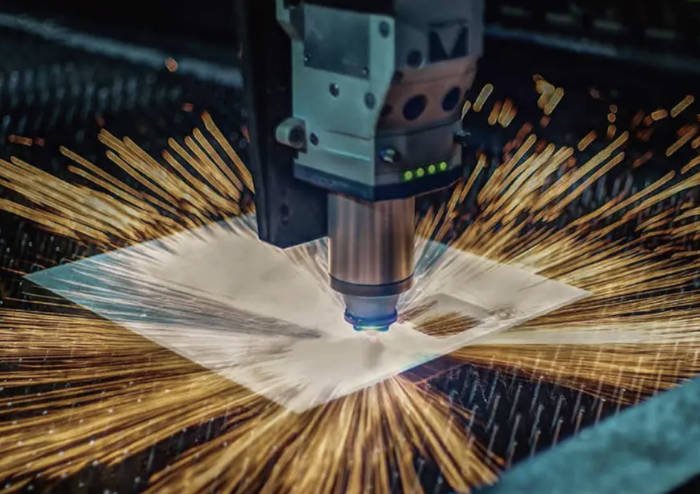

Cutting effect of carbon steel plate laser cutting machine

Why Choose SUNSHAN Sheet Metal Laser Cutting Machine

SUNSHAN is a leading supplier and manufacturer of fiber laser cutting machines in China. We specialize in the development, production and sales of unique metal laser cutting machines. Our extensive expertise allows us to offer the best products on the market and provide the best customer experience. Supplier and manufacturer in China.

Equipped with high-tech machines and advanced technology, SHINE can oem metal laser cutting machines according to customers’ needs with high cutting accuracy and fast speed.

Let SUNSHAN support you in your custom sheet metal laser cutting machine journey. We are committed to doing our best to upgrade and enhance your brand. Contact now! Custom metal laser cutting machine journey. We promise to do our best to upgrade and enhance your brand. Get in touch now!

Application areas of carbon steel plate laser cutting machine

OEM & ODM SUNSHAN Fiber Laser Cutter Machine

3015 4020 carbon steel plate laser cutting machine for sale

Carbon steel plate laser cutting machine adopts imported large gantry machine tool precision processing, after annealing and aging treatment to eliminate internal stress, the geometric accuracy of the machine tool is within 0.03mm. Automatic focus function, automatic cutting to reduce manual operation and improve production efficiency. Small heat-affected area, no melting and burr-free cutting kerf.

Stainless steel laser cutting machine

Stainless steel laser cutting machine is currently a faster and more efficient way to process. In the process if you can have strict requirements on the parameters, you can maintain the good corrosion resistance of such materials. The most important process parameters that affect the quality of stainless steel cutting are cutting speed, cutting accuracy, laser power, air pressure, etc.

aluminum laser cutter machine

Aluminum cutting machine fully automatic can help you solve, a device can be equivalent to the original four to five people, greatly reducing the cost of labor, which can partly improve the profits of aluminum doors and windows manufacturers.

SUNSHAN - China Carbon Steel Plate Laser Cutting Machine Manufacturer

At SUNSHAN, you are sure to find high quality, practical and durable fiber laser cutting machines for metal. We can supply them worldwide at very low prices.

Related Products

Carbon Steel Laser Cutting Machine information

Carbon steel is a metal material widely used in construction engineering, machinery and equipment, auto parts, hardware and tools, etc. Laser cutting is used by more and more manufacturers for cutting carbon steel because of its advantages of high precision, high efficiency and no consumables. Today we will introduce the carbon steel laser cutting machine.

Carbon steel is an iron-carbon alloy with a carbon content of 0.0218% to 2.11%. Also called carbon steel. Generally also contains a small amount of silicon, manganese, sulfur and phosphorus. Generally, the higher the carbon content in carbon steel, the greater the hardness and strength, but the lower the plasticity.

According to the use of carbon steel can be divided into carbon structural steel, carbon tool steel and free-cutting structural steel three categories, carbon structural steel is divided into engineering construction steel and machine building structural steel two.

Carbon structural steel is mainly used for railways, bridges, various types of construction projects, the manufacture of various metal components subject to static load and not important do not need heat treatment of mechanical parts and general welded parts.

Carbon tool steel is used to make edge tools, molds and gauges, etc. These carbon steels are generally delivered in annealed condition, but can also be delivered in unannealed condition according to the requirements of the demand side. Annealed steel hardness, fracture organization, reticulated carbide, pearlite organization, specimen quenching hardness, hardenability depth and steel surface decarburization layer depth should be in accordance with the Chinese national standards.

There are two main traditional ways of cutting carbon steel, one is to use the blade cutting machine cutting, one is to use the flame cutting machine cutting, flame cutting machine cutting carbon steel plate fast and efficient, but the traditional small flame cutting machine often requires workers to manually cut, manual operation is not only a certain degree of danger, and because of manual cutting so there is often a large error.

The CNC cutting machine is too expensive and difficult to operate. And flame cutting at the cutting edge often have the phenomenon of melting kerf, but also prone to burrs.

There are also a variety of carbon steel cutting beds on the market, but these cutting beds generally exist, after the workpiece is cut, the cutting edge is exposed, easy to cut workers, and the cutting process produces waste slag, it is difficult to collect and clean up the situation.

Recommended models: 3015 fully enclosed interactive fiber laser cutting machine series, you can choose different laser power models according to demand, the standard version of 1000 ~ 4000W, the high version of 6000 ~ 12000W.

The machine is precision processed by imported large gantry machine tool, and the internal stress is eliminated by annealing and aging treatment, and the geometric accuracy of the machine tool is within 0.03mm.

Gantry double rack and pinion, double servo motor drive structure, laser head equipped with automatic focus function, automatic cutting to reduce manual operation, perforation time reduced by 80% compared to ordinary cutting head, improve production efficiency.

Professional laser cutting software with graphic layout and sharp corner smoothing processing function, non-contact processing, small heat-affected area, no melting and burr-free incision.

Adopt encircling outer protection design, equipped with CE protection glass safety window, effectively protect the safety of operators.

Mainly used for carbon steel laser cutting, silicon steel, stainless steel, aluminum alloy, titanium alloy, galvanized sheet, aluminum zinc plating, copper and many other metal materials for fast cutting.

The above is the carbon steel laser cutting machine, smooth and safe and efficient incision of all content. Welcome to consult with GrandTech Yuming Laser Group for the selection of related laser equipment, the product line is rich and can surely meet your equipment needs.

1. Stainless steel surface rust.

Stainless steel rust is difficult to cut through, the cutting effect will also be affected, and there is rust blocking, may make the laser cutting on the easy to shoot back to the nozzle, the nozzle for burning cutting damage, the temperature is super high will also damage the components, once the jet nozzle found changes, cutting on the jet laser may appear offset, resulting in the jet nozzle inaccurate, which will also hurt the optical system and protection system, and even cutting explosion accidents occur. So, before cutting, do a good job of rust removal.

2. Stainless steel surface coating. Stainless steel surface cladding is often encountered in the processing, but if the traditional cutting process, completely unworkable. In cutting brushed or mirror stainless steel, generally have to use the film cutting technology, in order to ensure that the film is not damaged, usually we will first cut the side of the film, no film side facing down.

3. Stainless steel surface painting

This happens rarely, but also need to pay attention to. As many paints contain toxic substances, easy to produce toxic fumes when cutting, will be harmful to humans. Therefore, when using laser cutting machine painted stainless steel, the first thing to wipe off the surface paint.

With the renewal of the house now, people have high requirements for the pattern and quality of aluminum doors and windows, but now the price of aluminum continues to rise, in such an environment how to make aluminum manufacturers can stand invincible, a share of the market? Aluminum laser cutting machine is in such an environment came into being, aluminum laser cutting machine can solve the problem of aluminum doors and windows as well as the current situation.

Desktop aluminum laser cutting machine in the cutting time to ensure both the accuracy of cutting aluminum doors and windows, but also to protect the cutting time, there can not be too many consumables produced, or this will increase production costs, making aluminum doors and windows manufacturers to buy the original intention of the thick aluminum cutting machine.

Now the customer requirements of the pattern is also very strange, so if you want to or the original manual carving and cutting, it is too wasteful of labor costs, now desktop aluminum laser cutting machine can use the PLC system can be arbitrary design patterns and patterns, which makes no matter what kind of aluminum doors and windows customers need patterns, automatic aluminum laser cutting machine can help you solve, a device can be equivalent to the original of four to five people, greatly reducing labor costs, which can partly improve the profits of aluminum doors and windows manufacturers.

Laser aluminum cutting machine is specifically for aluminum doors and windows and the birth of cutting and engraving equipment, as the saying goes, if you want to be good at what you do, you must first benefit from its tools, so to get both quality and efficiency, but also want to reduce production costs to increase profits, then we must first find a suitable CNC fiber laser cutting machine.

As we all know, the core of the fiber laser cutting machine is a fiber laser, with a high energy conversion rate, in the processing of thin metal sheet both energy-saving, but also efficient, is the choice of sheet metal processing. However, fiber laser cutting machine can cut aluminum plate material?

Customers in the purchase of fiber laser cutting machine, will ask the question of whether they can cut aluminum, there are many laser cutting machine manufacturers salesman will be categorical to tell customers to cut to mislead customers to reach a deal. So whether it can really cut it?

In fact, we all know that the aluminum material is a highly reflective material, the absorption rate of the laser is very low, when the fiber laser cutting machine cutting aluminum, can not be absorbed by the aluminum light are reflected on the lens, and then transmitted to the fiber laser. In this case, not only the loss of the lens is great, but also a lot of damage to the laser, which invariably shortens the life of the laser.

1. the aluminum surface will be painted black, which can reduce the degree of reflection of the aluminum plate before cutting;

2. the parameters of the laser machine is not well adjusted, the processing, because the aluminum material is not resistant to high temperatures, the cutting process is more difficult to grasp, the cutting process is prone to burrs, you need to focus on controlling the process.

3. Cutting speed also needs to be controlled, too fast cutting is easy to produce burrs, too slow cutting speed will make the aluminum material cracks, affecting the quality of cutting.

Overall, the same power laser cutting equipment, fiber laser cutting machine cutting speed is higher than the speed of the YAG laser cutting machine.

In fact, there are many other highly reactive materials such as aluminum, because laser equipment is really sensitive to return light, may be unstable operation or damage to the laser lens during processing, and requires a higher power laser, greatly shortening the life of the laser. So, we do not use the laser cutting machine? Of course not!

Laser cutting machine can cut aluminum, aluminum in the processing process requires attention to a number of situations, aluminum is not resistant to high temperatures, the processing process requires patient debugging, at the same time, pay attention to the cutting speed. In addition, in the aluminum laser cutting machine cutting aluminum plate is recommended to use nitrogen, because of the special color of aluminum and to protect the uniform color of the cut products, nitrogen can well prevent oxidation and retain the characteristics of the material itself, the use of nitrogen is a better choice.

Aluminum is a material commonly used in many fields such as decoration, machine manufacturing, etc. Its high hardness, the ability to deform many times, and outstanding support capacity, and therefore in the vast construction field are mostly used. The cutting of aluminum is also a continuous process of progress, recently Guangyuan new debugging research and development of fiber laser cutting machine on aluminum cutting has shown quite good results.

The fiber laser cutting machine has a high-strength alloy steel welded bed with built-in reinforcement bars that can be cooled with the furnace 24 hours a day, ensuring the stability and durability of the machine’s high-speed operation.

In addition to stability, the ultra-fine fine spot effectively ensures that the laser cutting machine cutting accuracy reaches a high quality of 0.02mm, as well as servo motors and self-developed cutting control system, which are all powerful technical weapons of Guangyuan.

In addition, the most important is the high photoelectric conversion efficiency of the IPG fiber laser and automatic focus cutting head with a full guarantee in cutting speed and quality. The low power consumption, high efficiency, low cost and high quality of green environmental protection products, the addition of the dust-absorbing device on the beam is again a guarantee of this environmentally friendly green technology products, so that the production of the environment to high standards.