China Laser welding, cleaning and cutting three functions in one machine suppliers

SANSHEN specializes in laser cleaning machine manufacturing in China. We can use to provide you with laser cutting machine, laser welding machine, laser cleaning machine and other CNC laser equipment

Product Features

Laser Cutting

It is a portable handheld laser cutting machine for all kinds of metal cutting

Laser Welding

Can weld aluminum, stainless steel, titanium, gold, silver, copper, nickel, chrome and many other metals or alloys, also can be applied to various weld metals between different metals, such as titanium-gold, copper-brass, nickel-copper, titanium-molybdenum, etc.

Laser Cleaning

Remove rust, resin, coating, oil, paint, dirt for surface treatment by hobbyists and industrial manufacturers, effectively reducing machine maintenance costs and increasing industrial productivity

What is a 3 in 1 mini handheld laser welding cleaning cutting machine?

The 3-in-1 laser welding, cutting and cleaning machine is a powerful, user-friendly machine that replaces the original three machines with a single machine that is powerful and can be switched at will, while taking into account efficiency and quality.

Laser cleaning and welding cutting machine can not only clean the contaminants on the metal surface, but also cut and weld various metal materials. 3-in-1 fiber laser welding, cutting and cleaning machine with power range of 1000W-3000W is available. Three modes can be switched flexibly.

3-In-1 Handheld Laser Welding and Cleaning Systems Video

- Simple and fast: increased precision and time saving work

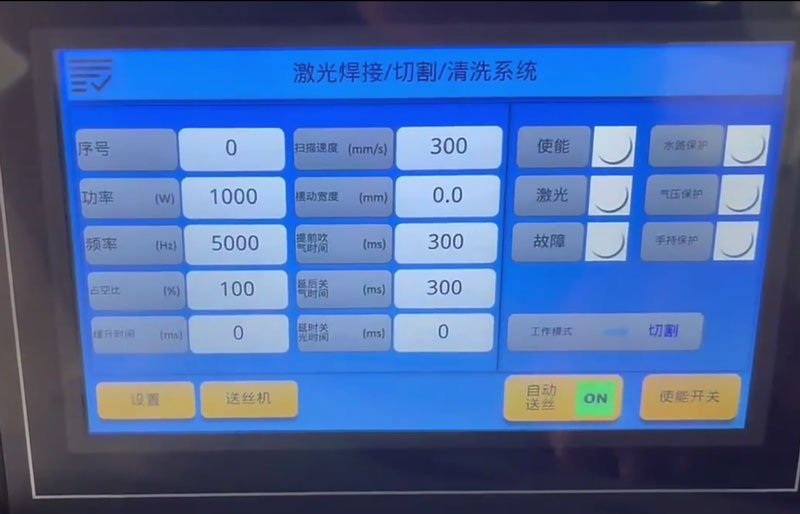

- simple interface for novices to learn quickly

- Variety of styles: many types to meet different needs

- Good cleaning effect: no space and location restrictions, flexible application scenarios

Machine type: series laser welding and cleaning system

Laser power: 1000W 2000W 3000W (optional)

Laser wavelength: 1064nm

Fiber length:Standard 10M / Max 15M

Welding speed range:0~120mm/sec

Chiller:Industrial chiller

Working ambient temperature range:15~35℃

Welding thickness recommendation:0.5-3mm

Working voltage : 220 volt

Cleaning width: 0-80MM

Focus height : 600MM

| Material | Power | Max. penetration mm |

| Stainless steel | 1000w | 0.5-3 |

| 1500w | 0.5-4 | |

| Galvanised sheet | 1000w | 0.5-1.2 |

| 1500w | 0.5-1.8 | |

| Aluminium alloy | 1000w | 0.5-2.5 |

| 1500w | 0.5-3 | |

| Carbon steel | 1000w | 0.5-2.5 |

| 1500w | 0.5-3.5 |

Fiber interface | QBH |

Laser wavelength | 1070±20nm |

Laser power | Laser power |

Intelligent protection function | Intelligent protection function |

Collimated focal length | 50mm |

Focus focal length | 400mm/600mm |

Scan range | 0-150mm |

Scan speed | 20000mm/s |

Effective clear aperture | 25mm |

Weight | 0.73kg |

Wire weight | max 25kg |

Wire core diameter | MAX Ø3.0mm |

Maximum wire feed speed | 80mm/s |

Motor type | 57 Stepper Motor |

Reduction ratio | 1:5 |

Gross weight | 16.2KG |

Working voltage | 220V(option) |

Dimensions | 560*240*472mm(L*W*H) |

| Tig Welders | Laser Welders | |

| Heat input | Very high heat | Very low calories |

| Deformation | Easy to deform | No deformation |

| Welding spot | Large welding spot | Fine welding spot, adjustable spot |

| Exterior | Unsightly, need polishing | Smooth and beautiful, no need to sand |

| Perforation | Easy to pierce | Not easy to perforate, can be controlled |

| Protective gas | Need argon | Need argon |

| Precision | general | Precision |

| Processing time | Long time | Short time |

| Safety | Ultraviolet light, radiation | Radiation-free |

3 in 1 Laser cut clean welding configuration.

The 3-in-1 laser welding, cleaning and cutting machine consists of a fiber laser generator, handheld laser gun, water chiller and a 3-in-1 control system for laser welding, cleaning and handheld cutting. Each handheld laser gun is portable, convenient and easy to use.

7 advantages of the Multifunctional 3 IN 1 Industry handheld laser welding cutting cleaning machine

1. Our machine can be used in sheet metal industry, hardware industry, new energy welding.

2. Can switch between welding, cutting and cleaning.

3. Intelligent protection system, mobile phone end APP and PC monitoring, real-time feedback on working status.

4. High threshold optics, better welding effect.

5. Multiple safety locks, high safety performance.

6. Through-body water-cooled design, more durable stability.

7. Ergonomic design, comfortable grip and easy to grip.

Easy change from welding to cutting by simply changing the nozzle and from cutting to cleaning by unscrewing the barrel

Flexible all-in-one solution for different applications, 1 minute change mode, multi-functional, efficient all-in-one solution, solving tedious processing pain points with ease and efficiency.

The laser head weighs just 788g, nearly 1/3 lighter than conventional handheld welding on the market, so you won’t get tired of working with it for long periods of time. Lightweight design, easy to hold and convenient, no pollution, no consumption, low cost, good controllability, no technical dependence, to meet the needs of fine processing

Touch screen control system with remote control, simple system operation interface, personalised process library, support for multiple language switching to meet global customer needs, ultra-long distance transmission control technology to meet long distance cleaning applications, with anti-touch and false press function, maximum safety protection

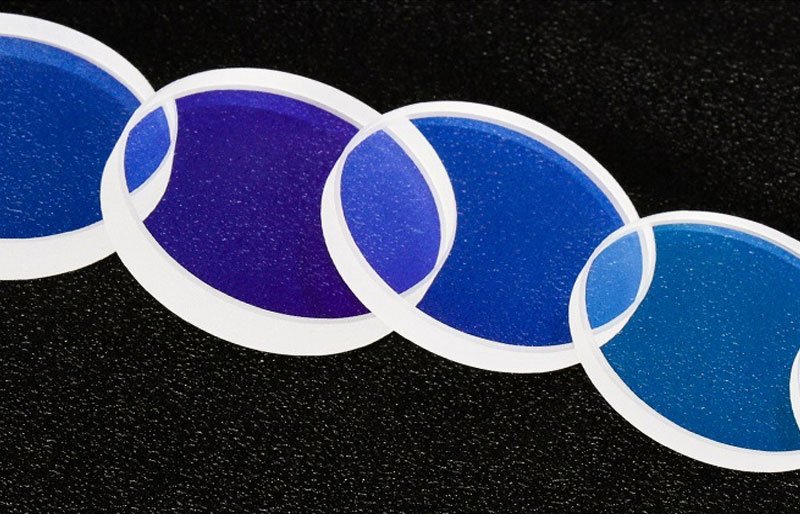

The high quality optics and protective lenses guarantee a higher fusion depth while being more durable; the fully sealed design greatly extends the working life of the machine.

Application Scenario.

3 in one Fiber Laser Welder Cutter Cleaner used in Kitchenware industry, household utensils, food security, automotive parts, electronic applications, hotel kitchen equipment, lift equipment, advertising signs, automotive decoration, sheet metal fabrication, lighting hardware, display equipment, parts, hardware products and other industries

How much does a 3 In 1 Handheld Laser Welding Machine cost?

The cost of a handheld fibre laser welding, cleaning and cutting machine varies greatly with the laser power. A new three-functional all-in-one laser welding, cleaning and cutting machine can cost from $15,000 to $22,000. Specify your requirements and get a quote for a SANSHEN fibre laser welding machine now. Delivery time is within 7-14 days.

You can tell us your working material, detail work by picture or video so that we can judge whether our machine can meet with your requirements or not. Then we can recommend you with the suitable model by our accumulated experiences.

Always a pre-production sample before mass production;

Always final Inspection before shipment;

You can send your materials to us by courier, we will mark you for free, and send you pictures and videos.

Tell us your material, detail requirements by words, pictures or video.

We will recommend you the suitable model with the reasonable price.

For the standard machine, the delivery time is 3-7 days after the payment.

For the non-standard machine, the delivery time is 7-15 days after the payment.

We have the instruction Book, Operational manual and Training Video inside the machine.

We also can provide the training on line by free.

Yes. We can provide the onsite service if you needed. But need the customer pay for the transport, hotel, food and 60USD/day.

Submit a Quick Quote

Why SANSHEN is Trusted by 500+ Clients

Our laser cleaners bring many benefits to many industries, businesses or projects. Here are the advantages of our services.

Cost-effective and fast production

We can quickly produce different laser welding and cleaning cutting machines and end products.SANSHEN offers fast production while ensuring high precision. We can provide OEM ODM for our customers, saving you money and gaining more benefits.

Professional technical training

We have professional technicians that enable us to produce different designs to support your customisation.