Under the epidemic, the development of the industrial market can no longer meet people’s needs purely by hand. The metal laser cutting machine has fast efficiency, high precision, and improves work efficiency. Many customers inquire about the price of the 1000w laser cutting machine and how thick the fiber laser cutting machine can cut. , let China laser cutting machine suppliers tell you now.

In the sheet metal cutting metal processing and manufacturing industry, a 1000W fiber laser cutting machine can theoretically process a steel plate with a thickness of about 10mm, but in practice, the laser cutting machine cannot reach its theoretical cutting thickness because of the energy conversion process. There must be a certain loss in it. Let’s talk about how thick the steel plate can be cut and the main reasons that affect the cutting thickness of the equipment.

Why does the sheet metal industry favor laser cutting equipment?

With the rapid development of human society and the faster and faster pace, we are all pursuing high-efficiency and high-quality things, and fiber laser cutting machines can meet the needs of various manufacturers.

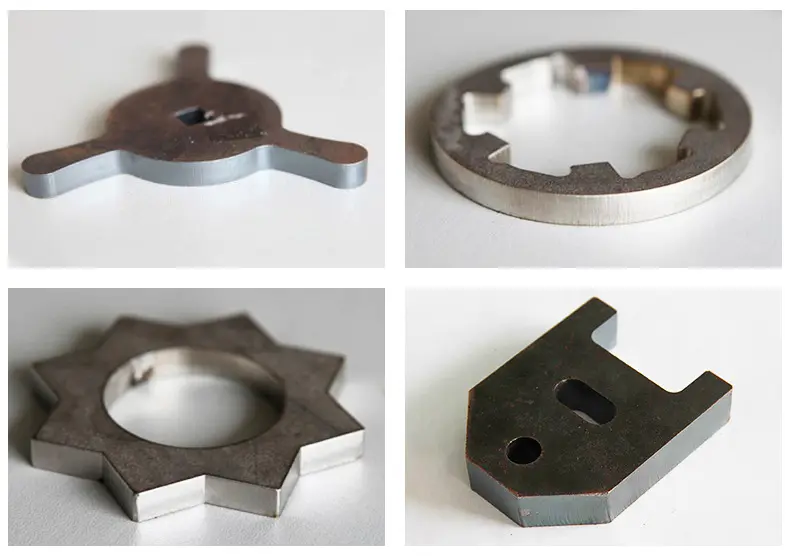

Now metal products are full of every detail in our life, ranging from aerospace to small pots and pans at home, but the processing of metal products is inseparable from the cutting machine. As the metal processing industry shifts from small batches to large ones For mass production, the past wire cutting has gradually failed to keep up with the trend of the times in terms of accuracy and speed, while the metal laser cutting machine can adapt to the shape, size, and material of a variety of materials, and at the same time, based on the high precision, high speed and high flexibility of the laser cutting machine, etc. Features, laser cutting machine has an irreplaceable position in the metal industry.

The metal industry is an important application market for laser processing. The domestic sheet metal industry competition has gradually transformed into high-tech product competition. In order to adapt to the development of the market, sheet metal processing has transformed the processing method. Laser processing technologies such as laser cutting and laser welding will be more and more applied in various industries.

Laser cutting machine has become a leader in the sheet metal processing industry with its excellent performance in non-contact processing, high precision, high speed, and high efficiency. As a high-precision processing method, metal laser cutting machines can process most materials, setting off an important revolution in the sheet metal processing industry.

2 factors affecting the thickness of laser cutting machine cutting

- Equipment accessories for fiber laser cutting machine.

Some unscrupulous merchants have branded lasers pretending to be imported lasers, and even replaced 1000W lasers with 500W lasers, which will cause the cutting thickness of the fiber laser cutting machine to fail to reach the theoretical thickness in the later use of the machine.

- Maintenance frequency and methods of fiber laser cutting machine equipment.

Fiber laser cutting machine equipment needs to take a break after working for a period of time. Reasonable maintenance of the fiber laser cutting machine equipment can ensure the service life and cutting quality of the fiber laser cutting machine equipment.

How to adjust the cutting accuracy of fiber laser cutting machine?

The cutting accuracy of the fiber laser cutting machine will decrease after a period of use. This error is generally caused by changes in focal length.

The first step is to adjust the light spot of the laser cutting machine to the minimum, and test the initial effect by experimental cutting.

The second step is to prepare a piece of paper or a scrapped workpiece, lay down the bottom of the laser head, and determine the optimal focus position and distance of the laser by moving the position of the laser head up and down.

Compared with traditional processing methods, the use of laser cutting machines improves processing efficiency and saves manpower and material resources, thereby bringing higher profits to enterprises and more in line with the increasingly competitive consumer market.