- 首页

- China 1kw 1500W 2000w 3kw Handheld Laser Welding Machine Manufacturer

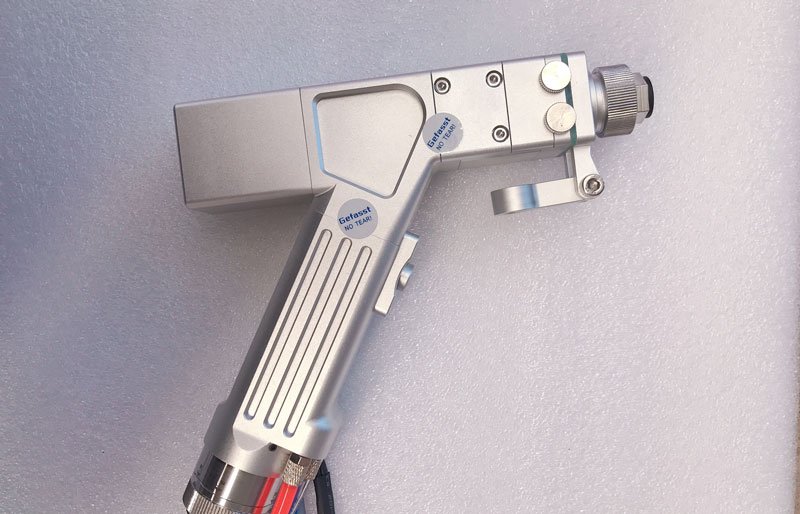

China 1kw 1500W 2000w 3kw Handheld Fiber Laser Welding Machine Manufacturer

Laser power: 1000w/1500w/2000w optional.

Laser wavelength: 1080nm.

operation mode: continuous/modulated.

Laser frequency: 50HZ.

Welding speed: 0-120mm/s.

cooling mode: water-cooled.

spot range: 0.5-5mm.

Operating temperature: 5-35°C.

Handheld laser welding machine, using a new generation of fiber laser, fill the gap of handheld welding in the laser equipment industry, with the advantages of simple operation, beautiful welding seam, fast welding speed, no consumables, welding in thin stainless steel plate, iron plate, aluminum plate and other metal materials, can perfectly replace the traditional argon arc welding, electric welding process.

Handheld fiber laser welding machine product advantages.

Easy to understand control functions, push button design, ready to use when you turn on the machine. The laser beam quality is excellent, the welding speed is fast, the weld seam is firm and beautiful, bringing the user an efficient and perfect welding solution. It can weld smooth and beautiful joints, and the weld seam is flat and free of air holes.

The working mode of handheld fiber optic welding machine, hand held welding, flexible and convenient, longer welding distance. Small welding impact area, will not lead to deformation, blackening, traces on the back of the problem, and the welding depth is large, solid welding and full melting.

Suitable for all kinds of complex welding seams, hand-held welding head, to overcome the limitations of the workbench. Hand-held welding torch can realize welding at any angle to any part of the workpiece. High photoelectric conversion rate, low energy consumption, long-term use can save a lot of processing costs.

Adopt four-dimensional ball screw table, imported servo control system, high welding accuracy and fast speed, equipped with rotary table, can realize automatic welding of large quantity products.

Welding graphics can be: point, line, circle, square or any graphics drawn by the software.

Handheld fiber laser welding machine has the advantages of easy operation, beautiful welding seam, fast welding speed and no consumables. It can be used to weld various metal plates and tubes: such as stainless steel plates, iron plates, galvanized and CS plates, aluminum plates, brass plates, other metal plates and tubes.

| Traditional welding | Laser welding | |

| Welding speed | Common | 4-10x faster |

| HeatAffected zone | large | small |

| Deformation | large | small |

| Bond strength with base material | Common | Excellent |

| Subsequent processing | Polish | No or very little polish |

| Consumables | any | Little |

| Operation difficulty | Complicate | Simple |

| Operator safety | Not safe | Safe |

| Impact on the environment | Pollutional | Enviromental |

| Welding fault tolerance | Good | Good |

| Pendular welding | No | yes |

| Adjustable spot width | No | Yes |

| Welding quality contrast | Bad | Excellent |

| Adjustable Welding mode | No | Six Mode |

| Material | Thickness Single side weld | Thickness Double side weld | Thickness Wire weld |

| Sianless steel | 4mm | 8mm | 3.5mm |

| Galvanized steel | 4mm | 8mm | 3.5mm |

| Mild steel | 4mm | 8mm | 3.5mm |

| Titanium alloy | 4mm | 8mm | 3.5mm |

| Aluminum | 3mm | 6mm | 2.8mm |

| Copper | 1.5mm | 3mm | 1.3mm |

What materials can be welded by handheld fiber welder

1、Mold steel

Handheld fiber laser welding machine can be applied to many types of mold steel welding, and the welding effect is better.

2、Carbon steel

Carbon steel is welded by handheld fiber laser welding machine with good effect, and its welding quality depends on the impurity content. In order to obtain good welding quality, the carbon content of more than 0.25% needs to be preheated. When steels with different carbon contents are welded to each other, the torch can be slightly biased to the side of the low carbon material to ensure the quality of the joint. Due to the very fast heating and cooling rate of the fiber laser welding machine when welding carbon steel. As the carbon content increases, the weld cracking and notch sensitivity increases. Medium and high carbon steels and common alloy steels can be laser welded well, but preheating and post-weld treatment are required to relieve stress and avoid cracking.

3, alloy aluminum

Laser welding of low-alloy high-strength steel, as long as the selected welding parameters are appropriate, you can get a joint with the mechanical properties of the parent material equivalent.

4、Stainless steel

In general, the welding of stainless steel is easier than conventional welding to obtain high-quality joints. Due to the high welding speed of laser welding and heat-affected zone is very small, reducing the phenomenon of overheating and the adverse effects of large linear expansion coefficient of stainless steel welding, the weld without porosity, inclusions and other defects. Compared with carbon steel, stainless steel due to low thermal conductivity, high energy absorption rate and melting efficiency is easier to obtain deep fusion narrow weld seam. With low-power laser welding thin plate, you can get the appearance of well-formed, smooth and beautiful weld joints.

5, copper and copper alloys

Welding copper and copper alloys are prone to unfused and non-welding problems, so should use energy concentration, high-power heat source and with preheating measures; in the workpiece thickness is thin or structural rigidity is small, no measures to prevent deformation, after welding is easy to produce large deformation, and when the welded joint is subject to greater rigidity constraints, easy to produce welding stress; welding copper and copper alloys are also prone to thermal cracking; porosity is copper and Copper and copper alloys are common defects when welding.

6, aluminum and aluminum alloys

Aluminum and aluminum alloys are highly reflective materials, aluminum and its alloys welding, as the temperature rises, the solubility of hydrogen in aluminum increases sharply, the dissolved hydrogen becomes a source of defects in the weld, the weld more porosity, and deep fusion welding root may appear cavity, the weld channel is poorly formed.

Laser welding machine can weld much more than these materials, laser welding can be carried out between a variety of dissimilar metals, research shows that the application of copper – nickel, nickel – titanium, copper – titanium, titanium – molybdenum, brass – copper, mild steel -Copper and many other dissimilar metals can be laser welded under certain conditions. For more products to be welded, you can contact us for a free sample test.

Handheld Laser Welding Machine Applications

Sheet metal processing, rail transportation, automobile, engineering machinery, agriculture and forestry machinery, electrical manufacturing, elevator manufacturing, household appliances, grain machinery, textile machinery, tool processing, petroleum machinery, food machinery, kitchenware and sanitary ware, decorative advertising, laser external processing services and many others.