The use of metal pipes in the industrial market is relatively high. For many companies, choosing CNC plasma pipe cutting machine or laser pipe cutting machine requires many factors to be considered. This article will tell you in detail how to choose for metal pipe cutting. I hope it will be helpful to you.

CNC Plasma Pipe Cutting Machine

What is cnc plasma pipe cutting machine

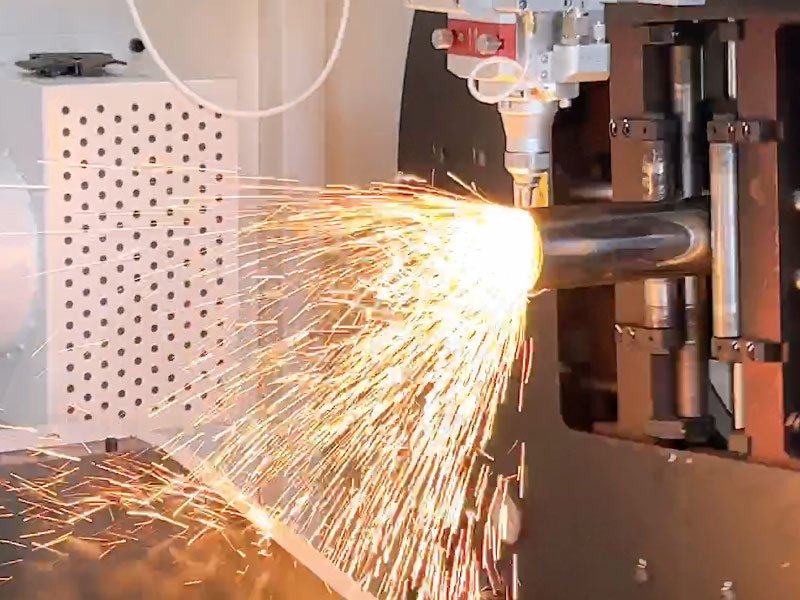

A CNC plasma pipe cutting machine uses a high-velocity jet of ionized gas (plasma) to cut through metal. The plasma arc is created by electrically heating a gas, which then melts and blows away the metal to form the cut.

Advantages of pipe plasma cutting machine

- Cost-Effective: Generally more affordable than laser cutting machines, both in terms of initial purchase price and operating costs.

- Cutting Speed: High cutting speeds, especially for thicker materials (typically above 6 mm).

- Material Thickness: Excellent for cutting thicker materials, often up to 50 mm or more, depending on the machine’s power.

- Versatility: Can cut through a variety of conductive materials, including steel, stainless steel, aluminum, brass, and copper.

- Portability: Some plasma pipe cutters are portable and can be used in different locations.

- Durability: Can withstand harsher environments and rough handling.

Disadvantages of cnc pipe plasma cutting machine

- Precision and Quality: Lower precision compared to laser cutting. The cut edges might require additional finishing.

- Heat-Affected Zone (HAZ): Larger HAZ, which can affect the material properties and require additional cooling time.

- Kerf Width: Wider kerf width compared to laser cutting, resulting in more material waste.

- Fumes and Noise: Generates more fumes, noise, and sparks during operation, requiring effective ventilation and safety measures.

Applications of cnc plasma pipe cutter

- Thicker Metal Fabrication: Ideal for cutting thicker pipes and plates.

- Construction and Heavy Industries: Often used in construction, automotive repair, and heavy machinery manufacturing.

- Budget-Conscious Projects: Suitable for projects where precision is less critical and cost is a major concern.

Laser Pipe Cutting Machine

What is laser pipe cutting machine

A laser pipe cutting machine uses a focused beam of light (laser) to melt, burn, or vaporize material, resulting in precise cuts. Common types include CO2 lasers and fiber lasers, with fiber lasers being more popular for cutting metal.

Advantages of laser tube cutting machine

- High Precision: Extremely precise cuts with minimal need for post-processing. Laser machines can achieve tight tolerances and complex geometries.

- Quality of Cuts: Smooth and clean cut edges with minimal burrs, reducing the need for secondary operations.

- Minimal HAZ: Smaller heat-affected zone compared to plasma cutting, preserving the material properties.

- Kerf Width: Narrower kerf width, resulting in less material waste.

- Automation and Control: Advanced automation features and software for intricate cutting patterns, improved efficiency, and reduced human intervention.

- Versatility: Capable of cutting a wide range of materials, including metals (steel, stainless steel, aluminum) and non-metals (plastics, wood, acrylics) with varying thicknesses.

Disadvantages

- Higher Cost: Higher initial investment and maintenance costs. Operating costs can also be higher due to energy consumption and the need for skilled operators.

- Material Thickness Limitations: Less effective for very thick materials (typically over 20-30 mm) compared to plasma cutting.

- Slower Cutting Speed for Thicker Materials: While excellent for thin materials, cutting speed decreases significantly for thicker sections.

- Reflective Materials: Cutting highly reflective materials (e.g., copper, brass) can be challenging for some laser types, though fiber lasers have improved capabilities.

Applications

- Precision Manufacturing: Ideal for industries requiring high precision, such as aerospace, automotive, electronics, and medical device manufacturing.

- Complex Geometries: Best for intricate designs and detailed cuts.

- Thin to Medium Thickness Materials: Optimal for cutting thin to medium thickness materials with high accuracy.

- High-Volume Production: Efficient for automated, high-volume production lines where consistency and speed are crucial.

CNC Plasma Pipe Cutting Machine VS Laser Pipe Cutting Machine

| Feature | CNC Plasma Pipe Cutting Machine | Laser Pipe Cutting Machine |

|---|---|---|

| Cutting Technology | Ionized gas (plasma arc) | Focused laser beam |

| Precision | Moderate | High |

| Cut Quality | Moderate to good | Excellent |

| Material Thickness | Thick (up to 50+ mm) | Thin to medium (up to 30 mm) |

| Speed on Thick Materials | Faster for thicker materials | Slower for thicker materials |

| Speed on Thin Materials | Moderate | Faster |

| Material Versatility | Conductive metals | Metals and non-metals |

| Cost | Lower initial and operating costs | Higher initial and operating costs |

| Maintenance | Less maintenance required | More maintenance required |

| Heat-Affected Zone | Larger | Smaller |

| Environmental Impact | More fumes and noise | Less fumes and noise |

| Portability | Portable options available | Generally stationary |

| Automation | Basic to moderate | Advanced |

| Suitable Industries | Construction, heavy machinery | Aerospace, automotive, electronics |

How much does CNC Plasma Pipe Cutting Machine & Laser Pipe Cutting Machine

Initial Investment

Tube Plasma Cutting Machine: Generally less expensive, with shop-quality machines ranging from $50,000 to $100,000.

Tube Laser Cutting Machines: Significantly more expensive, with new machines often costing over $300,000 and sometimes reaching up to $1 million.

Operating Costs

CNC Plasma Tube Cutter: Typically cost around $15/hour to operate.

Laser tube Cutting Machines: Generally cost around $20/hour to operate, with additional costs for safety accommodations

Material Compatibility Difference

CNC Plasma Pipe Cutter

Versatility: Can cut almost any electrically conductive material, including thick metals and industrial I-beams.

Limitations: Less effective with non-conductive materials and reflective metals.

Laser Pipe Cutting Machine

Versatility: Can cut a wide variety of materials, including metals, wood, plastic, and glass.

Limitations: More effective with thin materials (up to 25mm) and less effective with highly reflective metals

Conclusion

Choosing between a CNC plasma pipe cutting machine and a laser pipe cutting machine depends on your specific needs:

- CNC Plasma Cutting Tube Cutting Machine : Best for budget-conscious operations, cutting thick and conductive materials, and applications where speed and versatility are crucial.

- Laser Tube Cutting Machine : Ideal for high-precision applications, cutting a variety of materials including thin metals and non-metals, and where high-quality finishes are required.

Evaluate your material requirements, budget, and desired precision to select the most suitable cutting technology for your needs.

Related Article

- The Revolution Of Tube Laser Processing Machines In Modern Manufacturing

- Best Laser Tube Cutting Machines In China: Your Ultimate Guide

- Ultimate Buying Guide For Metal Tube Laser Cutting Machines: What You Need To Know

- Advantage Of Tube Laser Cutter In Contract Office Furniture

- Choosing A CNC Tube Laser Cutting System Exporter :The Ultimate Guide