china h shape laser cutting machine supplier manufacture

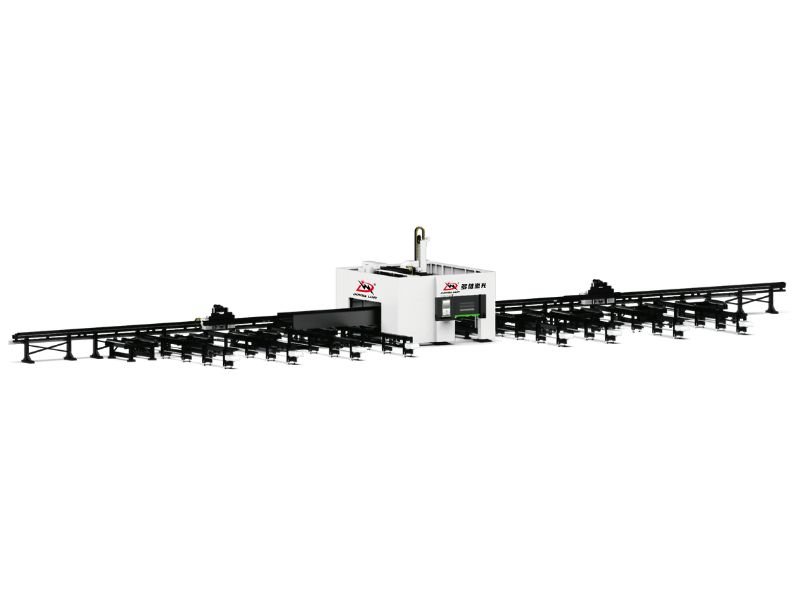

High efficiency steel h shape laser cutting machine (h beam laser cutting machine secondary processing line)

- Support bevel ± 45 ° cutting function

- Any port and graphic can realize zero tail material cutting

- H-steel surface height tracking control, four-side center calibration

- Prices : $90,449.90 to $194,815.18

description

H Shaped Laser Cutting Machine / H Beam laser Cutting Machine cuts, punches, bevels, locks, and marks into one, automatically detects contours, automatically centers and finds edges, can punch holes on the side, and is 3 times more efficient than a gantry. Process a piece of steel in 10 minutes.

Used for H shaped steel, I beam, channel steel and other profiles.steel and other profiles.

Used for cutting, hole cutting, locking, beveling, marking and scribing in one machine.

H shaped steel processing, one-stop solution

It can easily realize a series of functions on H-shaped steel, such as cutting, locking, beveling, marking, etc.

Cut off

Beveling

Cutting holes

Open Section steel laser cutting video

H beam laser cutting automatic production line video

Section steel laser secondary processing line video

Technical Parameters

- Brand: Dowell Laser

- Power: 6000w 12kw 15kw 20kw 30kw

- Cutting method: laser

- Wing width: 100-600mm

- Web width: 100-1250mm

- Standard processing length: 26m

- Perforation cutting thickness: 1-40mm

- Maximum positioning accuracy: 30m/min

- Bevel cutting: ±45°

- Maximum processing wall thickness: 40mm

- Customizable designs

- Single section steel** weight: 5000kg

- Cutting accuracy: 0.05mm

- Production place: China

- Equipment size: 30m*10m

Features

- 1. High cutting precision: accurately complete the cutting of various complex graphics and contours, suitable for refined and fine-dimensional processing

- 2. Efficiency: significantly shorten the production cycle, improve production efficiency, and reduce production costs.

- 3. Environmentally friendly: No contact with materials is required, reducing noise and pollution, making it more environmentally friendly.

- 4. Highly customizable: It can be controlled through computer software, and customized cutting can be carried out according to customer needs to meet the diverse needs of customers.

Optional accessories

Automatic Feeding Device

Square tubes, round tubes, rectangular tubes, I-beams, channel steels, etc. are loaded to the designated position, and 5 tubes can be loaded at the same time, and the height can be automatically adjusted to match the tubes, effectively ensuring the reliability of the support.

Side Mounted Loading Device

Suitable for cutting heavy metal pipes, it can realize fully automated operations such as automatic feeding, automatic cutting, and automatic discharging, thereby greatly improving production efficiency; improving the utilization rate of pipes, maximizing the use of steel pipe materials, and reducing waste;

Configuration details

Movable laser cutting head

Advanced control system, capable of secondary development, using laser sensors for precise control

Dual station workbench

Save cutting time, improve work efficiency, automatically search for materials and center, save space, and cut in sections

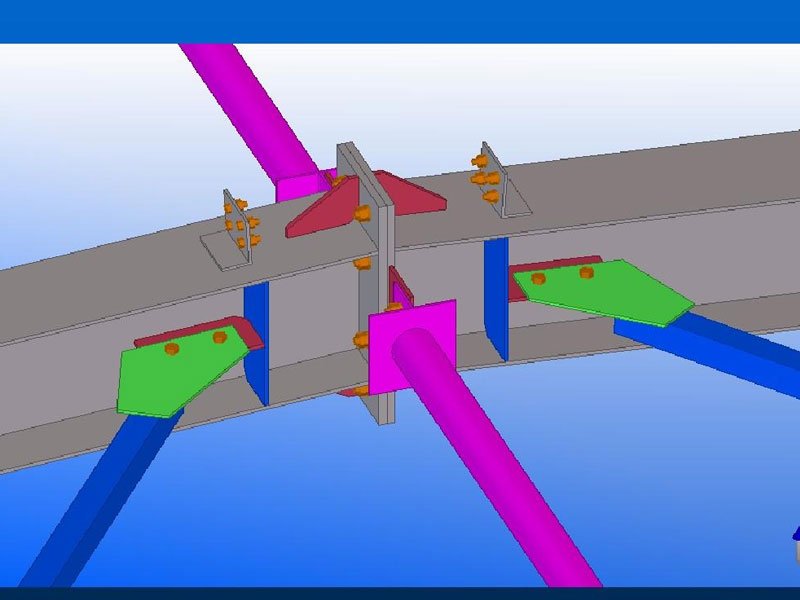

professional TEKLA system

Tekla steel structure 3D modeling system supports various tower connection forms bevel cutting processes

ACU swing mechanism

5-axis machining center milling, with high reliability, high-strength aluminum material, high structural strength, high processing accuracy, good overall rigidity, can be equipped with a variety of models of laser cutting heads, integrated line scanning measurement mechanism

WisCut Laser Cutting Software

3 in 1 cutting software: plane cutting, groove cutting, steel cutting; German Beckhoff 3D six-axis CNC system; H-beam online measurement, compensation, cutting, hole opening, marking, cutting, groove opening integrated software functions to achieve a variety of cutting processes

WisNest Steel Nesting Software

Drawing import, one-click processing, model import, drawing recognition, set programming, process compilation, material search and centering, complete processing, and obtain finished products. It supports circular cutting and various splicing methods: such as miter, V-type, center Z-type and edge Z-type, etc., to achieve true zero tail material!

laser cutting examples

Suitable for metal materials, especially for cutting H-shaped steel (also known as I-beam or H-steel), such as channel steel, angle steel, carbon steel, to achieve multi-functional cutting, slotting and opening, graphics and text, etching, and bevel cutting Arc opening and other functions.

laser cutting machine uses application

How Much is h shape laser cutting machine price cost

The price of H steel laser cutting machine ranges from $90,449.90 – $194,815.18. The price is different according to different power models. If you want to buy the most affordable and cheapest equipment, you can consult us.

h shape laser cutting machine manufacturer

FAQ

The maximum thickness that an H shape laser cutting machine can cut depends on the laser power and the material being cut. Typically, for a high-power machine (e.g., 6000W to 12000W):

Operating an H shape laser cutting machine is relatively easy, thanks to:

- User-Friendly Interface: Modern machines feature intuitive touch-screen interfaces and graphical displays.

- Software Integration: Compatible with various CAD/CAM software for seamless design import and processing.

- Automation Features: Includes automated loading and unloading systems, material handling, and cutting processes.

- Training and Support: Manufacturers often provide comprehensive training sessions and user manuals to ensure smooth operation.

The typical lifespan of a laser profile cutting machine ranges from 10 to 15 years. This lifespan can be influenced by several factors including the machine’s build quality, the frequency and intensity of its use, and how well it is maintained.

Regular maintenance, proper usage, and adherence to the manufacturer’s guidelines can extend the lifespan of the machine beyond this typical range.

Ensuring timely servicing, replacing worn-out parts, and keeping the machine clean and properly calibrated are essential practices for maximizing the operational life of a laser profile cutting machine.

Safety features commonly included with H shape laser cutting machines are:

- Enclosed Cutting Area: Prevents direct exposure to the laser beam.

- Interlock Systems: Automatic shutdown if safety doors are opened during operation.

- Fume Extraction: Built-in systems to remove hazardous fumes and particles.

- Emergency Stop Buttons: Easily accessible emergency stop buttons to quickly halt operations.

- Protective Glass: Viewing windows made of protective glass that block harmful laser wavelengths.

Yes, most reputable manufacturers offer warranties and after-sales services:

- Warranty Period: Usually, a 1 to 3-year warranty covering parts and labor.

- Technical Support: Access to technical support via phone, email, or on-site visits.

- Spare Parts: Availability of spare parts and consumables.

- Training and Installation: Often included in the purchase package to ensure proper setup and operation.

Yes, many china cnc laser profile cutting machine manufacturers offer customization options to meet specific customer requirements:

Tailored Configurations: Customizable laser power, bed size, and automation features.

Special Attachments: Options for rotary attachments, specialized cutting heads, or additional safety features.

Software Customization: Integration with specific software or custom software development for unique applications.

Material Handling Systems: Customizable loading and unloading systems to match specific workflow needs.