With the continuous development of technology, laser cleaning technology has attracted more and more attention in the field of metal surface treatment. Among them, laser rust removal technology is favored for its high efficiency, environmental protection and accuracy.

This article will explore in depth how to use laser technology to effectively remove rust on metal surfaces, as well as the working principle, equipment type, application field, preparation and cost of the technology.

How does laser cleaning work?

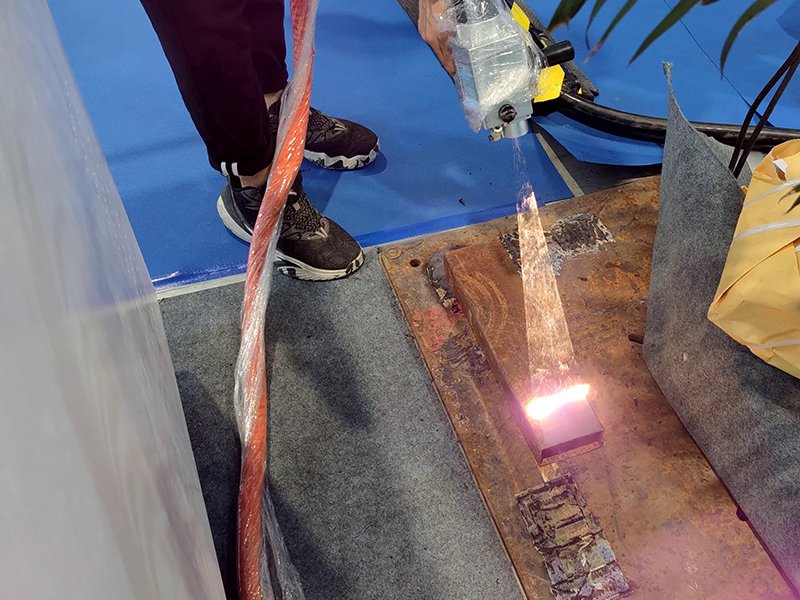

The working principle of laser cleaning is based on the interaction of laser light with matter. When a high-energy laser beam irradiates the rust layer, the rust layer quickly absorbs the laser energy and evaporates or decomposes instantaneously. This process is called laser ablation. Laser cleaning typically uses pulsed lasers, which provide high peak power to ensure rapid and effective rust removal while avoiding excessive heat transfer to the substrate and preventing damage to the substrate.

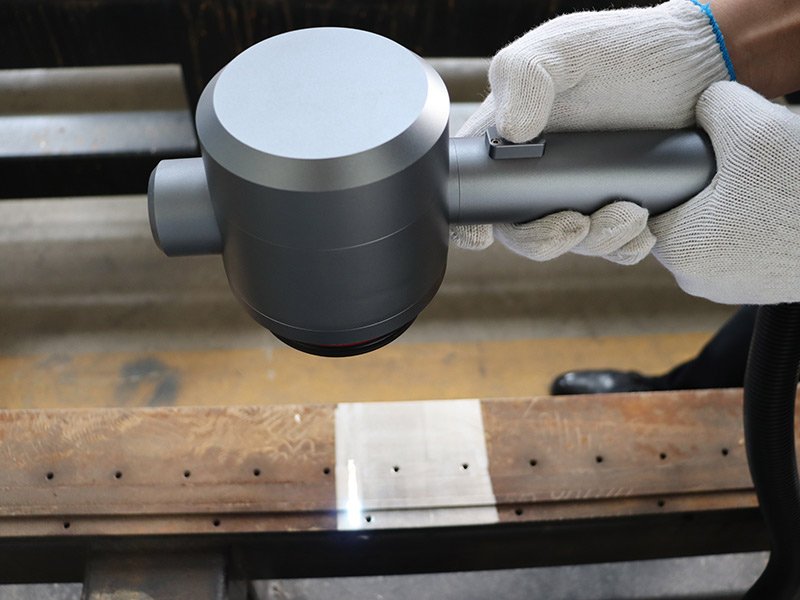

Types of Handheld Laser Rust Removal Machine

Continuous Wave (CW) Laser Cleaners:

These cleaners use a constant, low-powered laser beam to heat and vaporize rust and other contaminants on the surface of the material. CW cleaners are well-suited for removing light rust, paint, and oil from flat surfaces.

Pulsed Laser Cleaners:

These cleaners use short, high-powered laser pulses to break down rust and other contaminants on the surface of the material. Pulsed cleaners are more powerful than CW cleaners and can be used to remove heavier rust, as well as weld marks and coatings.

How Does Laser Cleaning Technology Function?

The core of laser cleaning technology lies in the precise control of laser parameters. Choosing the right laser wavelength and power is key to effective cleaning. Typically, lasers are equipped with specialized software that allows operators to adjust laser parameters for different materials and levels of rust. In this way, laser energy can be precisely controlled to ensure efficient rust removal without damaging the substrate. Cooling systems and protective devices are also important components of laser cleaning equipment to ensure operational safety and stable equipment operation.

Benefits Of Removing Rust with a Laser

- Non-contact cleaning: The laser rust removal process does not require contact with the substrate, avoiding wear and damage caused by traditional mechanical methods.

- Environmentally friendly: Laser rust removal does not require chemicals, avoiding environmental pollution and chemical disposal problems.

- High precision: The laser beam can be precisely focused on the rusted area to achieve local cleaning without affecting the surrounding uncorroded areas.

- Versatility: Not only can lasers remove rust, they can also remove paint, grease, and other contaminants.

Applications of Laser Rust Removal in the Industrial

Automobile manufacturing: used to remove rust on the body and parts to improve product quality and service life.

Aerospace: For high-precision cleaning of aircraft parts to ensure safety and performance.

Manufacturing industry: used for the maintenance of equipment and tools to extend their service life and work efficiency.

Will Laser Rust Removal Remove Paint?

Laser rust removal usually also removes layers of paint from the surface because the laser heats and vaporizes the paint material. Therefore, special attention needs to be paid when using laser rust removal. If you do not want to remove paint, you can protect the paint layer from being affected by adjusting laser parameters or using masking technology.

How to Prepare Surfaces for Laser Paint Removal?

- Clean the surface: Make sure the surface is free of grease, dust and other contaminants, which helps the laser energy to be transmitted efficiently.

- Mask non-target areas: Use protective material to cover areas that do not require paint removal to prevent laser damage.

- Choose the right laser parameters: Adjust laser power and scanning speed according to paint type and thickness to ensure efficient paint removal without damaging the substrate.

Why are Laser Rust Removal So Expensive?

- High-tech: Lasers and control systems require high-precision manufacturing and strict quality control.

- R&D costs: Continuous technological R&D and innovation require substantial capital investment.

- Equipment maintenance: Laser equipment has high maintenance and upkeep costs, and key components need to be replaced regularly.

- Training needs: Operating laser rust removal equipment requires professional training to ensure safe and effective operation.

Limitations and Challenges of Laser Rust Removal

- Material limitations: Some materials are not sensitive to lasers and do not clean well.

- High cost: The initial equipment investment and maintenance costs are high, and it is suitable for high value-added application scenarios.

- Complex operation: Professionally trained operators are required to ensure correct use of the equipment.

- Safety risks: High-energy lasers have potential safety risks and require strict safety protection measures.

Training and Education in Laser Cleaning

Basic theoretical knowledge:

Laser principles: including basic principles such as laser generation, wavelength selection, and power control.

Materials Science: Understand how different materials respond to lasers so you can choose appropriate cleaning parameters.

Equipment operation skills:

Equipment Setup: How to properly install and calibrate laser cleaning equipment.

Parameter adjustment: Adjust laser power, frequency and scanning speed according to different cleaning tasks and materials.

Equipment maintenance: Routine maintenance and troubleshooting to ensure long-term stable operation of the equipment.

Safety precautions:

Personal Protective Equipment: Use appropriate eye protection, protective clothing, and gloves to prevent laser injury.

Safe operating environment: Make sure there are no flammable items in the work area, and set up safety warning signs and isolation belts.

Emergency handling: Master the basic methods of handling laser accidents and emergencies.

Practical training:

Simulation operation: Master the operation and parameter adjustment of the equipment through simulation exercises.

Practical application: Carry out actual cleaning tasks under the guidance of instructors and accumulate practical experience.

Continuing Education and Certification:

Regular training: regularly attend professional training courses to update knowledge and skills.

Certification examination: Pass the certification examination and obtain the qualification certificate for operating laser cleaning equipment.

Future Trends in Laser Rust Removal

Through systematic training and education, operators can not only master the operating skills of laser cleaning technology, but also effectively avoid safety hazards and improve work efficiency.

As technology continues to advance, laser rust removal technology is also developing. Here are some future trends:

Intelligence and automation:

Future laser rust removal equipment will be more intelligent and automated, equipped with advanced sensors and artificial intelligence algorithms to achieve adaptive cleaning and automatic fault diagnosis.

Portable and multifunctional devices:

Portable laser cleaning equipment will be lighter and more efficient, suitable for a variety of scenarios. At the same time, multi-purpose equipment will be able to handle different types of contaminants, not just rust removal.

Green and environmentally friendly technologies:

As environmental protection requirements increase, laser cleaning technology will pay more attention to environmental performance and reduce energy consumption and pollutant emissions.

Reduce costs:

Through technological improvements and large-scale production, the cost of laser rust removal equipment is expected to gradually decrease, allowing it to be used in more fields.

Wide application areas:

In addition to traditional industrial applications, laser rust removal technology will gradually expand to new fields such as cultural relic protection, building restoration and home maintenance, providing a wider range of solutions.

Led by these trends, laser rust removal technology will play a more important role in the future and promote the improvement of cleaning and maintenance levels in all walks of life.