Laser metal cutting machine is one of the necessary equipment for enterprises in the industrial market. Many customers are curious about “How Much Is a Laser Metal Cutting Machine”. This article describes this topic.

What is laser metal cutting machine

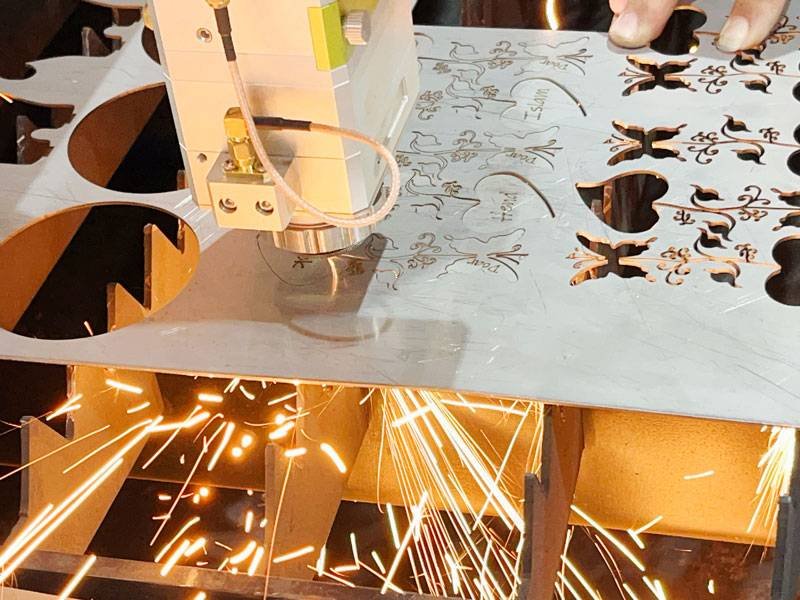

Laser metal cutting machine is a precision numerical control (CNC) machine for metal processing using a laser beam. It uses a focused laser beam to melt, vaporize or blow away materials and cut metal sheets and profiles according to the process design software. The cutting accuracy is high, the efficiency is fast, and the slit is narrow.

Best Laser Cutter For Beginners In 2024: The Ultimate Guide

Importance and application of laser metal cutting technology

Importance of metal cutting laser machining:

Improve production efficiency: Laser cutting is fast and can be automated, greatly shortening the production cycle.

High cutting accuracy: The laser beam is finely focused, enabling high-precision 2D and 3D cutting to meet complex machining requirements.

Reduce material loss: Laser cutting has a small heat-affected zone, reducing material deformation and waste.

Wide application field: suitable for cutting various metal materials, used in many industries.

Application

- Sheet metal processing: used to manufacture various metal parts, chassis, casings, etc.

- Aerospace: used for cutting lightweight and high-precision metal parts such as aircraft and spacecraft.

- Automobile manufacturing: used to cut automobile body frames, parts, etc.

- Electronic products: used to cut electronic components such as mobile phone frames and circuit boards.

- Other fields: advertising signs, medical apparatus, hardware products and other industries are also widely used laser cutting technology.

Factors affecting the price of cnc laser metal cutting machine

Machine size and cutting capabilities

Larger cutting bed size and higher cutting thickness capabilities mean a higher price.

Machines capable of cutting thicker sheet metal typically require more powerful lasers and sturdier structures, which come with increased costs.

Laser power and type

Laser power directly affects cutting thickness and speed. Higher power lasers can cut thicker metal and are more expensive.

Different laser types (e.g. CO2 lasers, fiber lasers) also affect the price.

Automation and additional features

Additional functions such as automatic feeding systems, chip removal systems, and smoke filtration systems can improve production efficiency and safety, but they will also increase costs. The complexity of the CNC system also affects the price.

Brand and reputation

Well-known brands of laser cutting machines usually have higher quality and better after-sales service, and their prices are relatively high.

After-sales service and warranty

A longer warranty period and improved after-sales service means higher costs, but can reduce subsequent maintenance and repair costs.

Cost breakdown

Buying a CNC laser metal cutting machine requires considering not only the initial purchase price, but also the cost of:

Initial purchase price

This is a major expense, and the exact price depends on the various factors mentioned above.

Installation and commissioning costs

Laser cutting machines usually require professional engineers to install and commission them, which incurs additional costs.

Operating costs

Including various expenses during daily use:

Power consumption:

The operation of a laser cutting machine sheet metal requires power consumption, and the cost will vary depending on the frequency of use and power consumption.

Maintenance and repair:

Regular maintenance and occasional repairs can incur certain costs.

Consumables:

Some consumables are used in the laser cutting process, such as auxiliary gases, cutting head nozzles, focusing lenses, etc., which need to be replaced regularly.

Where to find the best cnc laser metal cutting machine

- Online marketplaces: Alibaba, eBay, and other e-commerce platforms typically offer various brands of laser cutting machines for sale.

- Manufacturer’s website: Most laser cutting machine manufacturers’ official websites provide product information and quotation consultation channels.

- Industrial supply companies: Some industrial supply companies will sell various brands of laser cutting machines and provide related consulting and after-sales services.

- Before choosing a laser cutting machine, it is recommended to shop around and choose the right model based on your cutting needs, budget, and future development plans.

How Much Is a Laser Metal Cutting Machine

Entry level machines 1000w-3000w: Prices usually range from US$10,000 to US$40,000. These machines are typically smaller, less powerful, and have more basic functions, making them suitable for use in personal studios or small businesses.

Mid range machines 6000w-12kw: The price is usually between US$20,000 and US$60,000. This type of machine is larger in size, more powerful, and more versatile, and can meet the cutting needs of most businesses.

High-end machines 20kw 30kw 60kw: The price is usually above US$60,000. This type of machine has the largest cutting size, highest power and most complete functions, and is suitable for industries that require extremely high cutting accuracy and efficiency, such as aerospace, precision manufacturing, etc.

Comparison with other metal cutting technologies

Laser cutting vs plasma cutting

Laser cutting has higher cutting accuracy, narrower slits, and smaller heat-affected zones, and is suitable for cutting thin metal sheets and precision parts.

Plasma cutting is faster and cheaper and is suitable for cutting thicker sheet metal.

Laser cutting vs. waterjet cutting

Laser cutting can cut various types of metal materials, while waterjet cutting is only suitable for cutting some specific materials, such as aluminum, stainless steel, glass, etc.

Laser cutting has higher cutting accuracy and narrower kerfs, while waterjet cutting has stronger cutting capabilities and can cut thicker materials.

Cost-Effectiveness Analysis:

While metal laser cutting machines may have higher upfront costs compared to alternative technologies, their superior precision, speed, and versatility often result in lower overall production costs and higher efficiency in the long run.

Factors affecting return on investment

Machine Price: Initial purchase cost is one of the major factors that affects ROI.

Production efficiency: The cutting speed and accuracy of the machine directly affect production efficiency, which in turn affects ROI.

Material loss: Laser cutting has a small heat-affected zone and low material loss, which can improve ROI.

Operating costs: Expenses such as power consumption, maintenance and repairs, consumables, etc. will affect ROI.

Calculating ROI for Laser Metal Cutting Machines

ROI can be calculated by the following formula: ROI = (net income / investment cost) x 100%

- Net income = sales revenue – operating costs

- Investment cost = machine price + installation and commissioning costs

ROI can be calculated by comparing the total cost of ownership (including initial investment, operational expenses, and maintenance costs) with the financial benefits derived from increased production efficiency, reduced material waste, and additional revenue generated from increased capacity or expanded capabilities.

Future trends and forecasts

Advances in Laser Technology:

Continued advancements in laser technology, including higher power densities, improved beam quality, and enhanced automation, will further improve the speed, precision, and efficiency of laser metal cutting machines.

Impact of Industry 4.0 and Automation:

Integration with Industry 4.0 technologies such as artificial intelligence, Internet of Things (IoT), and predictive maintenance will enable greater automation, data-driven decision-making, and optimization of laser metal cutting processes.

Potential Changes in Pricing Models:

Manufacturers may adopt subscription-based or leasing models for laser metal cutting machines, offering greater flexibility and affordability for businesses with varying production needs.

Conclusion

CNC laser metal cutting machine is an important metal processing technology with the advantages of high efficiency, precision and flexibility, and is widely used in many industries. When purchasing a laser cutting machine, you need to consider factors such as machine price, performance, function, after-sales services, and calculate the return on investment to choose the most suitable model.

- CNC Vs Laser Cutter: The Best Choice For Metal Processing?

- Industrial Laser Cutters: A Comprehensive Guide

- China Wholesale 1530 Fiber Laser Cutting Machine Factories

- Choose The Right Fiber Laser Cutting Machine

- Applications Of Precision Laser Cutting Machines In China

- Difference Between Fiber Laser Cutting Vs Co2 Laser Cutting