In the field of metal manufacturing, precision, and speed are topics that customers are more concerned about. In the cutting of pipes, cutting pipes above 200mm has always been a headache. For such large round pipes, how should they be cut, and how to use 200mm round pipe Laser cutting machine, this article will explain it in detail.

200m Round Tube Laser Cutter

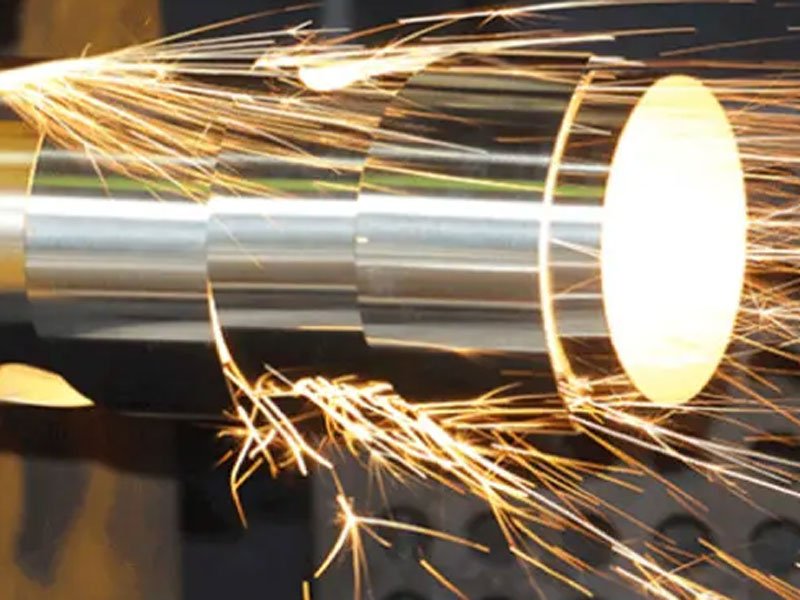

The 200mm tube laser cutting machine is changing the way metal manufacturing works. This high-tech machine has become an integral part of many manufacturers and fabricators around the world due to its advanced technology and precision. Ordinary metal tubes are transformed into intricate, precise, unmatchable workpieces by this beast.

One of the main benefits of a 200 mm round tube laser cutting machine is that it can easily cut through tough materials. Instead of relying on traditional methods that require physical effort and often take a long time, this machine uses lasers to effortlessly slice through even some of the most difficult materials. Clean-cutting which meets or exceeds all quality standards.

This state-of-the-art device offers a range of benefits that make it a good option for metal fabricators. It is versatile enough to be used in any given industry such as automotive, aerospace, and construction among others. The 200mm round tube laser cutting machine will suffice regardless if you wish to come up with complex designs or simple forms like rectangular boxes among others.

Benefits of Using a 200mm Round Tube Laser Cutter

Ensure accuracy:

Precision capabilities ensure every cut is accurate and consistent. This level of accuracy is critical to an industry where even the slightest deviation can lead to costly errors or safety hazards.

Efficiency improvements:

Traditional cutting methods often require multiple steps and a lot of manual labor, which is time-consuming and error-prone. 200mm round tube laser cutting machine, manufacturers can significantly reduce production time by automating the cutting process.

Versatility:

It can handle a variety of materials, including stainless steel, aluminum, copper, and more. This versatility makes it a valuable asset for metal fabricators working with different types of materials.

Applications 200mm Round Tube Laser Cutting Machine

200mm round tube laser cutting machines are suitable for a wide range of uses and industries. This highly developed machine is used in everything from car parts to construction components.

Automotive field

The precision cutting of exhaust pipes, chassis parts, and structural parts is done using a 200mm round tube laser cutting machine. These machines are capable of manufacturing complex shapes with tight tolerances and are therefore invaluable amid the stringent requirements set by the automotive industry.

Aerospace

Manufactures tubes for aircraft frames, engine components, and hydraulic systems. By using 200mm round tube laser cutters, they can deliver the precision and reliability required for critical aerospace parts to meet stringent quality standards.

Achitechive

Handrails, railings, or decorative elements. Architects and designers can turn their dreams into reality as the equipment can precisely cut different materials.

How Laser Cutting Reduces Production Time

The metal manufacturing industry has been transformed by laser cutting technology (which includes 200mm round tube laser cutters) because it has reduced production times greatly. Many traditional methods of cutting have several steps i.e. marking, clamping, and hand cutting. This process is time-consuming and prone to errors.

Laser cutting technology simplifies automation. The machine follows design stipulations precisely and cuts accurately defined materials. Manual intervention is unnecessary in this automated system; thus, reducing possibilities for error.

In comparison with conventional ones, laser cutting technology enables higher rates of cutting. Production time can be reduced through the use of a focused beam that quickly melts or vaporizes materials. Increased efficiency leads to cost savings for manufacturers as well as for manufacturers themselves.