In modern industry, the efficiency and effectiveness of cleaning and maintaining equipment is essential to maintain the efficient operation of the production line. Dowell, as a professional laser equipment manufacturer established for 15 years, has accumulated rich experience and excellent technology in the field of laser cleaning. With its unique advantages, Dowell laser cleaning machine has become an ideal choice for users in various industries.

This article will introduce in detail the five advantages of using Dowell laser cleaning machine.

Environmentally friendly and efficient

No chemicals

Traditional cleaning methods often rely on chemical solvents that are not only harmful to the environment but also pose a threat to the health of operators. Dowell laser cleaning machines use physical methods to clean without the use of any chemicals. The laser cleaning process produces very little waste, greatly reducing environmental pollution and health risks.

Energy efficient

Dowell laser cleaning machines have efficient energy utilization and can complete large-area cleaning tasks in a short time. Its efficient cleaning ability not only improves production efficiency, but also reduces energy consumption, thereby reducing the company’s operating costs.

Precise control

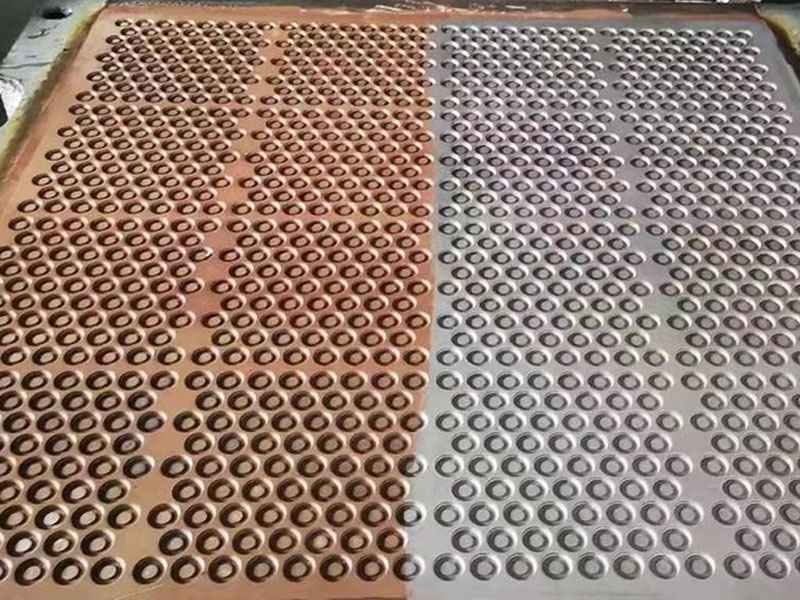

Fine cleaning

The Dowell laser cleaning machine can precisely control the energy and focus of the laser beam, allowing it to perform delicate cleaning operations. Whether it is complex surface structures or tiny details, the Dowell laser cleaning machine can easily handle it and ensure the uniformity and consistency of the cleaning effect.

Adjustable parameters

Users can adjust the parameters of the laser cleaning machine, such as laser power, scanning speed and focus position, according to different cleaning needs. This flexibility allows Dowell laser cleaning machines to adapt to a variety of different application scenarios and materials to provide the best cleaning results.

Non-contact operation

Damage-free cleaning

The Dowell laser cleaning machine uses a non-contact laser beam to clean, avoiding the physical damage to the substrate caused by traditional mechanical cleaning methods. This non-damaging cleaning method is ideal for high-value equipment and components where surface integrity needs to be protected.

Extend equipment life

Since laser cleaning does not cause wear or damage to the surface of the equipment, it can effectively extend the service life of the equipment and reduce maintenance and replacement costs. This is especially important for industrial equipment that requires frequent cleaning.

Wide scope of application

Compatible with multiple materials

Dowell laser cleaning machines are suitable for cleaning a variety of materials, including metal, plastic, ceramics and glass. Its wide applicability makes it ideal for users in different industries, whether it is aerospace, automotive manufacturing or electronics, you can find a suitable application.

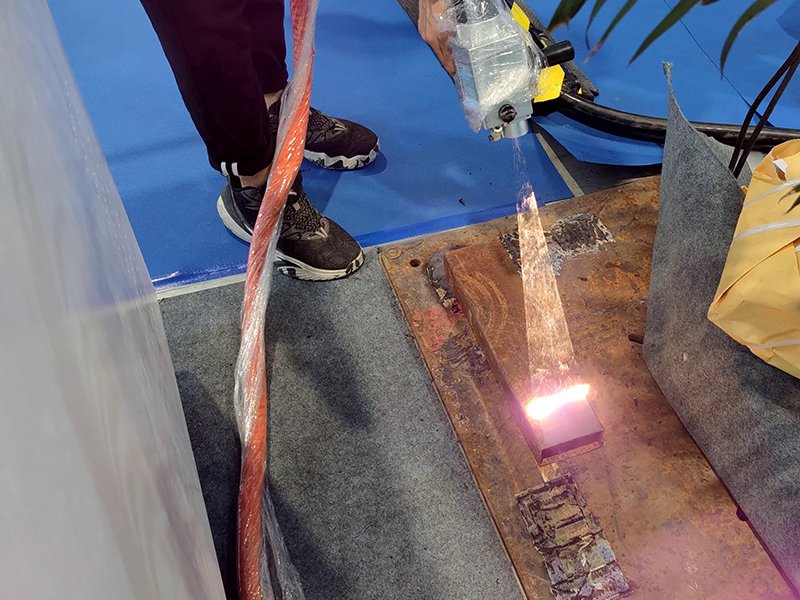

Diverse applications

Dowell laser cleaning machines can not only be used to remove rust, oil and oxides, but can also be used in various processes such as surface pretreatment, coating removal and cleaning before welding. Its diverse application range greatly improves the equipment’s use value and return on investment.

Intelligent operation

High degree of automation

Dowell laser cleaning machines are equipped with advanced control systems that can achieve highly automated cleaning operations. Users only need to set the cleaning parameters, and the equipment can automatically complete the cleaning task, greatly reducing the complexity and errors of manual operations.

Real-time monitoring and adjustment

Through the intelligent control system, users can monitor the cleaning process in real time and adjust parameters according to actual conditions. This intelligent operation method not only improves the stability of the cleaning effect, but also identifies and solves potential problems during the cleaning process to ensure the smooth operation of the production line.

Reliable quality and considerate service

With 15 years of technology accumulation, the quality of Dowell laser cleaning machines has been widely recognized in the industry. At the same time, the company also provides professional after-sales service and technical support to ensure stable and efficient operation of the equipment.

Conclusion

As a professional laser equipment manufacturer with 15 years of experience, Dowell is committed to providing customers with high-quality, efficient laser cleaning solutions. Using Dowell laser cleaning machines, users can not only enjoy multiple advantages such as environmental protection, high efficiency, precise control, non-contact operation, wide application and intelligent operation, but also significantly improve production efficiency and product quality. In the future, Dowell will continue to innovate and optimize products to provide users in various industries with better services and more advanced technical support.