In our daily life, auto parts, historical buildings, etc. come into contact with the air for a long time, and oxidation reactions will occur, causing surface rust or some paint marks. The traditional paint removal method has some drawbacks, and there will be some damage to the surface of the substrate. With the advancement of science and technology, the advent of laser paint removal tools is a good solution.

In this guide, we’ll explore the world of laser paint and rust removal tools, exploring what they are, how they work, their benefits, applications, and more. Whether you’re an industry professional or a DIY enthusiast, I hope this guide has been helpful to you.

What is a Laser Paint Removal Tool?

The laser paint removal tool uses the high-energy heat generated by the laser to ablate the metal surface to remove the paint on the metal surface, evaporating the surface coating without damaging the substrate.

Laser Ablation: Laser ablation works by absorbing laser energy into the paint layer, which causes it to break apart at the molecular level. This process is highly controlled, allowing for precise removal of paint without affecting the substrate.

Types of Laser Paint Removal Tool for Sale

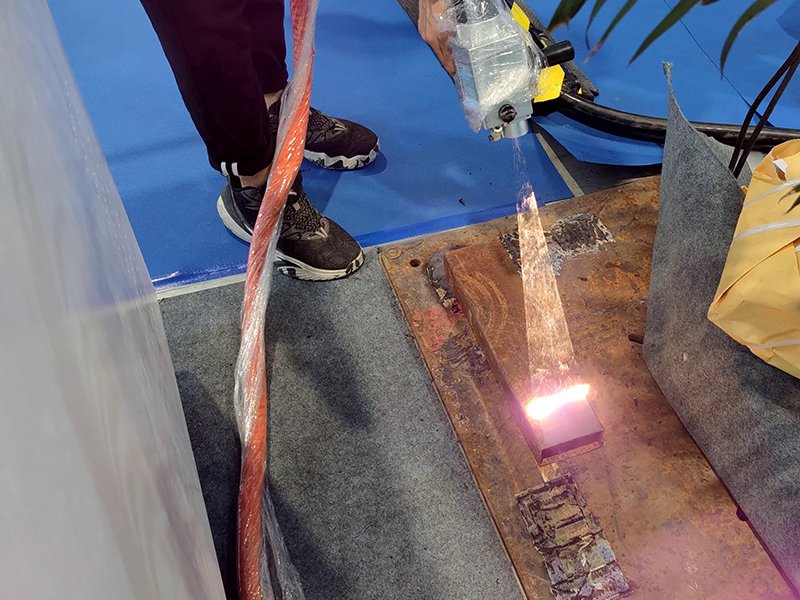

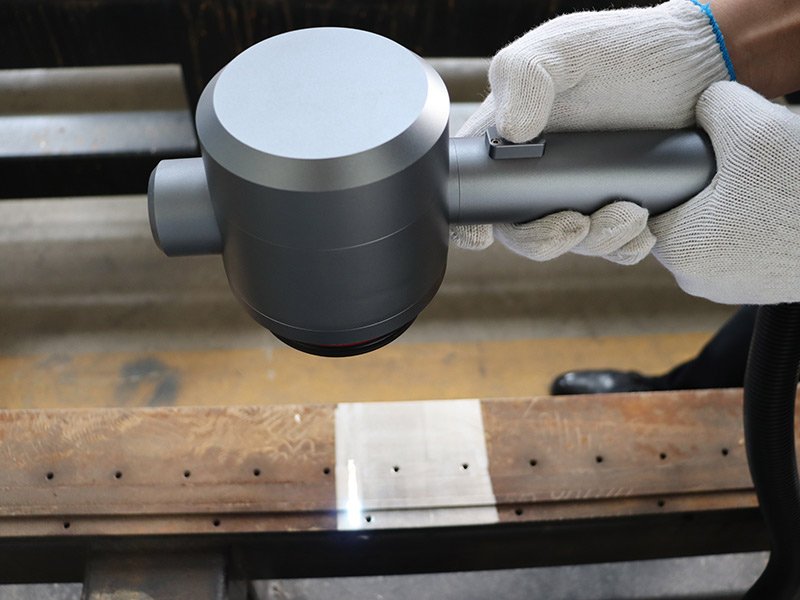

Handheld Laser Cleaning Machine for Rust Removal

Features:

Flexible and portable: Small and light, flexible to operate, can easily reach small spaces.

Precise positioning: Equipped with a red light auxiliary aiming system to ensure cleaning accuracy.

Versatility: Can be used for rust removal, paint removal, oxide layer removal, etc.

Backpack laser cleaning machine

Features:

Strong mobility: Backpack design, convenient for cleaning over a large area.

Strong endurance: Equipped with a large-capacity battery, it can work continuously for a long time.

Easy operation: Friendly human-machine interface, simple and easy to learn operation.

Portable Laser Paint Removal

Features:

Precision and Control: The laser can be targeted to specific areas, removing paint without damaging the underlying material.

Speed and Efficiency: The process is much faster than traditional methods, saving time and labor costs.

Environmentally Friendly: No harmful chemicals or abrasive materials are used, making it a clean and environmentally friendly option.

Safety: The non-contact nature of laser cleaning eliminates the risks associated with chemical contact or inhalation of harmful particles.

Versatility: Suitable for a wide range of materials, including metals, plastics, and ceramics.

Portability: These machines are designed to be easily transported and used in different locations

Advantages of Laser Paint and Rust Removal Tool

Precision and efficiency:

Fine control: The ability to adjust the laser settings ensures that only layers of paint are removed, leaving the underlying surface intact.

Speed: Laser tools can remove paint faster than manual methods, especially on complex surfaces or hard-to-reach areas.

Environmentally friendly:

Chemical-free: Unlike chemical stripping, lasers do not require harmful solvents or chemicals, making them a cleaner, safer choice.

Minimal waste: Paint is broken down into dust and small particles that are easier to clean up and dispose of responsibly.

Versatility:

Multi-surface applications: Laser tools can be effectively used on a variety of surfaces, including metal, wood, concrete, and more.

Layered removal: They can be fine-tuned to remove specific layers of paint without disturbing the underlying material.

Safety:

Reduce surface damage: Lasers are gentle on substrates, which is especially important for delicate or high-value surfaces.

Operator safety: Modern laser tools are equipped with safety features to minimize risks to operators, such as automatic shutoffs and protective barriers.

How Much Is Handheld Laser Paint Removal Tool Price

At present, the laser paint removal tool cost on the laser cleaning market is generally between 5,000 and 20,000 US dollars, because the power size, configuration, branding impression and so on of the machine have a great impact.

When purchasing, it is crucial to compare features, performance, and warranty information.

If you want to know more about the price of laser stain removal tools, you can consult us to get the latest product quotation.

Factors affecting laser paint removal tool cost:

- Laser power: Higher wattage lasers typically cost more.

- Brand and reputation: Well-known brands often command higher prices.

- Features: Additional features like automatic focus, adjustable power settings, and portability can influence the price .

- Manufacturer location: Import taxes and shipping costs can impact the final price.

Applications of Laser Paint Removal Tools

Industrial Applications

Automotive Industry:

- Removing paint from car bodies for restoration or repainting.

- Cleaning engine parts.

- Preparing surfaces for welding or coating.

Aerospace Industry:

- Removing paint and coatings from aircraft parts.

- Preparing surfaces for maintenance and repair.

Shipbuilding and Marine Industry:

- Removing marine growth and paint from ship hulls and components.

- Preparing surfaces for coating and repair.

Manufacturing:

Cleaning molds and dies.

Removing coatings from metal parts.

Preparing surfaces for welding or assembly.

Artifacts and Restoration

Art Restoration:

- Removing old varnish or paint from sculptures and paintings.

- Cleaning artifacts without damaging the original material.

Architectural Restoration:

- Removing old paint from historic buildings and structures.

- Cleaning stone and brickwork.

Other Applications

Medical Device Sterilization: Removing contaminants from medical devices.

Electronic Industry: Cleaning circuit boards and components.

Construction: Removing paint from concrete and other surfaces.

How to Choose the Right Laser Paint Removal Tool

Power and Wavelength:

Laser Power: The power output of a laser determines how quickly and efficiently it removes paint. Industrial applications typically require higher powers, while DIY projects require lower powers.

Wavelength: The wavelength of a laser affects its ability to interact with different materials. Shorter wavelengths are better for metals, while longer wavelengths may be better for organic materials like wood.

Portability and Size:

Handheld vs. Fixed: Handheld lasers are portable and versatile, making them great for small tasks or field work. Fixed systems are more powerful and better suited for large-scale industrial operations.

Costs vs. Benefits:

Initial Investment: Laser paint removal tools can be expensive, but the long-term savings on labor, materials, and waste disposal can make them a worthwhile investment.

Operating Costs: When evaluating the total cost of ownership, consider factors such as energy consumption, maintenance, and the availability of replacement parts.

Manufacturer Reputation and Support:

Customer Support: Choosing a reputable manufacturer with strong customer support can greatly improve your experience.

Warranty and After-Sales Service: A good warranty and reliable after-sales service

Conclusion

The laser paint and rust removal tool represents a major leap forward in metal surface preparation and restoration, and is ideal for manufacturing companies in terms of precision, efficiency, and environmental protection. As laser technology rapidly develops and advances, these applications will be more widespread.

FAQ

What materials can laser paint removal machine work on ?

Metals: Steel, aluminum, copper, brass, and stainless steel are common applications.

Plastics: Many types of plastics can be cleaned without damage.

Stone: Marble, granite, and other natural stones are suitable for laser cleaning.

Wood: Laser technology can remove paint from wood without damaging the underlying material.

Ceramics: Tiles, porcelain, and other ceramic surfaces can be cleaned with lasers.

Note: The effectiveness of laser paint removal can vary depending on the specific material and paint type. It’s essential to test a small area before proceeding with the entire surface.

How safe are laser paint stripping machine to use ?

Eye protection: Always wear laser safety goggles to protect your eyes from harmful radiation.

Ventilation: Ensure proper ventilation to remove fumes and particles generated during the cleaning process.

Skin protection: Wear gloves and protective clothing to avoid skin contact with debris.

Fire safety: Be aware of potential fire hazards and have a fire extinguisher readily available.

Operator training: Proper training is essential to understand the machine’s operation and safety procedures.

How do I maintain a laser that removes paint ?

Regular cleaning: Keep the machine clean and free of debris.

Lens care: Protect the laser lens from damage and keep it clean.

Cooling system: Ensure the cooling system is functioning properly.

Software updates: Keep the machine’s software up-to-date.

Professional service: Schedule regular maintenance checks by qualified technicians.

Can I use a laser stain removal tool for DIY projects?

Laser technology is advancing at a rapid pace, and using laser paint removal tools for DIY projects may not be practical or safe. These machines are often expensive and require expertise and safety precautions.

For most DIY paint removal projects, chemical strippers or heat guns may be a more appropriate and convenient option. However, if you have a specific project in mind and are willing to invest in the necessary equipment and safety measures, consulting a professional laser cleaning service may be an option.