When it comes to cutting metal tubes with precision and efficiency, metal tube laser cutting machines are the go-to choice for many industries. Whether you’re in the automotive, aerospace, or construction industry, these machines offer unparalleled accuracy and speed. However, choosing the right machine can be daunting given the variety of options available.

Selecting the most suitable metal tube laser cutter for your needs can be a complex task. This guide will help you understand the key factors to consider when purchasing, ensuring you make an informed decision.

Metal tube fiber laser cutting machine price factors

Initial cost

The initial cost of the machine is an important factor. Prices range from a few thousand dollars to hundreds of thousands of dollars, depending on the machine’s capabilities and features. It is important to create a budget and find the machine that provides the best value within your budget.

Operating costs

Consider operating costs, including electricity, maintenance, and consumables such as laser gas and replacement parts. Higher-powered lasers generally consume more electricity. Maintenance costs will also vary depending on the complexity and build quality of the machine.

Factors to consider when buying the best metal tube laser cutting machine

Laser power

Laser power is a key factor in determining cutting capabilities. Generally, the higher the power, the faster the cutting speed and the thicker the material that can be cut.

- 2-4 kW: Suitable for light to medium-duty applications

- 6 kW and above: Suitable for heavy industrial applications and can cut thicker materials

Cutting speed and accuracy

High cutting speeds increase productivity, while high accuracy ensures cutting quality.

Look for a machine with a fast positioning system

Check the XY axis positioning accuracy, ±0.05mm or better is preferred

Consider machines with space jump and flying cutting functions to improve efficiency

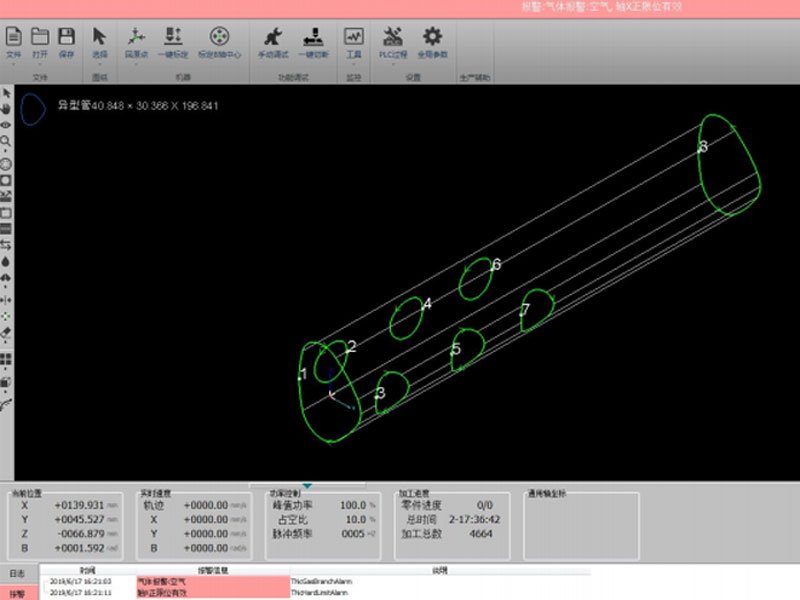

Software and control systems

- User-friendly software and control systems can significantly improve operational efficiency.

- Look for an intuitive interface and comprehensive functions

- Make sure the software supports common CAD/CAM file formats

- Consider machines with remote monitoring and diagnostic capabilities

What Are The Best Tube Pro Laser Cutting Software?

Material handling capabilities

Evaluate the machine’s material handling capabilities to ensure it meets your needs.

Check maximum tube diameter and length

Consider whether the machine can handle a variety of tube shapes (round, square, rectangular, etc.)

Evaluate automatic loading and unloading systems for increased efficiency

Maintenance and support

Regular maintenance is essential to maintaining the performance and longevity of the machine.

Ask the manufacturer about maintenance schedules and requirements

Check spare parts availability and lead times

Evaluate the technical support and training provided by the manufacturer

Budget considerations

When evaluating total cost of ownership, think beyond the initial purchase price.

Consider operating costs, such as energy consumption and maintenance expenses

Evaluate the machine’s life expectancy and return on investment

Consider financing options or leasing possibilities

Safety features

Safety should be a top priority. Look for machines with advanced safety features, such as:

Emergency stop button

Safety interlocks

Laser shield

Brand and Manufacturer Reputation

Research Brands

Research the reputation of different brands and manufacturers. Look for reviews and recommendations from other users. Brands with a proven track record for quality, reliability, and customer support are usually safer choices.

After-Sales Support

After-sales support is crucial, especially if you’re investing in a complex machine. Make sure the manufacturer offers a strong support service, including training, maintenance, and technical assistance. A solid warranty is also essential.

Conclusion

Choosing the best laser cutting machine for metal tubes requires careful weighing of multiple factors. By considering your specific needs, budget, and long-term goals, you can find the best machine for your business. Remember, the cheapest option is not always the most cost-effective – investing in a high-quality, reliable machine will generally provide a better return in the long run.