China professional 3d laser tube cutting machine manufacturer

Industrial 3D Tube Laser Cutting Machine for Sale for Square Tube, Round Tube

3D tube laser cutting machines are advanced tools used for cutting tubes, pipes, and profiles with high precision and efficiency.

- Power: 3000w 6000w 12kw 15kw 20kw 30kw

- Materials: Carbon steel or stainless steel

- Metal pipe type: square tube, round tube, rectangular tube, oval tube, angle steel, channel steel, H-beam

- Optional: fully automatic loading and unloading, movable chuck

Introduction

3D laser tube cutting machine can not only cut on a two-dimensional plane, but also perform accurate three-dimensional cutting of three-dimensional shapes in the three directions of X, Y, and Z (including marking, hole transfer, etc.). It supports cutting of various tube shapes, including round tubes, rectangular tubes, special-shaped tubes, etc.

It has attracted attention for its fast processing speed, short tail material, fully automatic loading (optional) and strong applicability.

Technical Parameters

- Brand: Dowell Laser

- Power: 3000w-60kw 3d square tube laser cutting machine

- Working width (mm):6m 9m 12m 24m

- X-axis machining stroke: 0-300mm

- Y-axis machining stroke: 0-11000mm

- Z-axis machining stroke: 0-180mm

- Maximum load weight: 374 lbs.

- X/Y axis repeat positioning accuracy: ±0.02

- X/Y axis positioning accuracy: ±0.05mm/500mm

- Maximum positioning acceleration: 2.4G

- Power supply: three-phase 380V/50/60Hz

- Customizable super large format

3D Laser tube Cutting video

3d tube laser cutting machine

3d square tube laser cutting machine video

Configuration

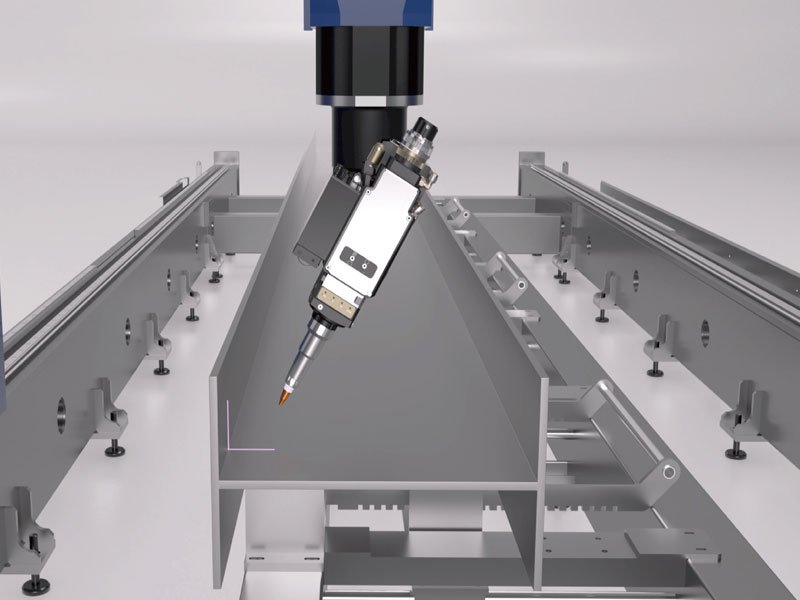

3D laser cutting head

Combined with the B-axis, it can achieve a maximum bevel of 45 degrees for various pipes. It is easy to install, stable in cutting, and has excellent performance.

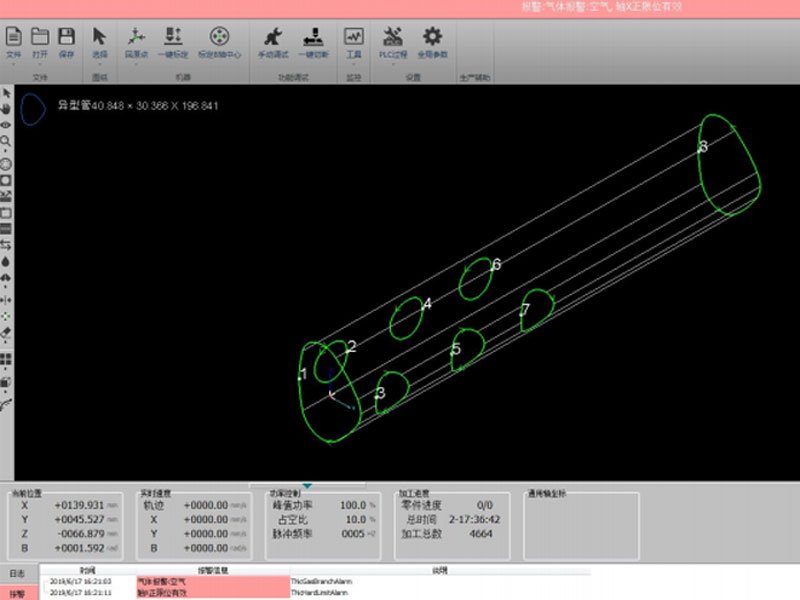

Metal pipe cutting system

The CNC metal pipe laser cutting system offers high precision, speed and flexibility. The technology enables complex cuts, reduces waste and increases the efficiency of the production process in these industries.

Loading and unloading device

Optional automatic loading and unloading device can be used to realize batch cutting of square tubes, rectangular tubes and oval tubes, saving labor and improving work efficiency

3d square tube laser cutting machine Features

Versatility: These machines can cut tubes and pipes of various shapes, including round, square, rectangular, and other profiles.

Precision: 3D laser cutting provides high accuracy, with some machines achieving final accuracy of ±0.1 mm compared to ±2-5 mm with conventional technologies.

Efficiency: The process consolidates multiple operations (cutting, drilling, beveling) into a single step, significantly reducing production time and handling.

Size range: Machines can typically handle tubes from 12 mm to 610 mm in diameter and up to 18 m in length

Automation: Many systems feature automatic loading and unloading, as well as intelligent monitoring and setup functions

Design flexibility: The technology allows for complex cuts and joint designs, enabling innovative product development and improved structural designs.

Cost-effectiveness: By eliminating the need for multiple machines and reducing material waste, 3D tube laser cutting can be more economical for many applications.

Material compatibility: These machines can work with various materials, including mild steel, stainless steel, and aluminum.

3D cutting capability: The machines typically have 5 or 6 axes of motion, allowing for complex 3D cuts, including beveled edges for welding preparation

Software integration: Advanced CAD/CAM software is used for programming and optimizing cutting operations

differences between 2D and 3D tube laser cutting machines

Cutting capability:

2D machines cut flat, two-dimensional shapes on tubes

3D machines can cut intricate, three-dimensional shapes and angles on tubes

Axes of motion:

2D machines typically have 3 axes of motion

3D machines have 5 or 6 axes, allowing for complex 3D cuts

Cutting head movement:

3D machines require constant adjustment of the laser cutting head to remain perpendicular to the tube surface, maintaining cut quality

Applications:

2D is suitable for simpler tube cuts

3D excels at complex structural parts like automotive components

Precision:

Both offer high precision, but 3D can maintain accuracy on curved surfaces and complex geometries

Flexibility:

3D machines offer greater flexibility for cutting various tube shapes, sizes, and thicknesses

Cost:

2D machines are generally simpler and more affordable

3D machines require higher initial investment due to their complexity

Efficiency:

3D machines can consolidate multiple operations (cutting, drilling, beveling) into one step, potentially improving overall efficiency

Design possibilities:

3D cutting allows for more innovative joint designs and structural improvements in tubular components

Material handling:

3D machines can more easily handle tubes of various profiles (round, square, rectangular) and sizes up to 610 mm in diameter

application

Aerospace:

Used to process various complex-shaped aviation parts, such as aircraft piping systems and structural frames, ensuring high-precision and complex-shaped processing requirements.

Automobile manufacturing:

Cut parts such as car bodies and exhaust pipes, which often require precise dimensions and complex shapes.

Electronic equipment:

Components such as conductive plates and electronic devices, which have strict requirements on precision and quality.

Medical equipment:

Process various precision medical devices, such as surgical instruments and stents, which have extremely high standards for precision and cleanliness.

Construction industry:

Production of pipes such as doors, windows, and stair railings. These applications require precise cutting of materials and beautiful surface treatment.

Furniture manufacturing:

Used for the processing of pipes, such as the frame structure of metal furniture, providing a variety of designs and precise dimensions.

Petrochemical industry:

Cutting pipeline systems, which have special requirements for the corrosion resistance and processing accuracy of materials.

Shipbuilding:

Cut hull structures, pipelines and other components, which need to withstand the harsh conditions of the marine environment.

How Much is thick 3d square tube laser cutting machine price

3d laser tube cutting machine price is related to the thickness of the tube being cut, power, configuration, etc., dowell 3d laser tube cutting machine cost $ 27584.68 – $ 57927.83.

If you want to know the specific price, you can consult dowell laser.

china 3d tube laser cutting machine factory manufacturer

15 years of focus on the production and research and development of laser equipment, professional laser tube cutting machine factory, can meet the OEM ODM needs of different customers, the appearance, power, model, size, color of the equipment can be customized, providing you with the most affordable price on the market.

FAQ

What materials are suitable for 3D tube laser cutting machines?

3D tube laser cutting machines are mainly used to cut metal materials such as carbon steel, stainless steel, aluminum alloy, and can also be used to cut some non-metallic materials.

How do the cutting speeds of 2D and 3D laser cutting machines compare

2D laser cutting machines are generally faster due to their simpler mechanics, while 3D laser cutting machines are slower due to the added complexity of handling three-dimensional shapes.

What is the cutting thickness of 3D tube laser cutting?

The cutting thickness of 3D laser tube cutting depends on the power of the laser and the characteristics of the material. Generally speaking, the cutting thickness is between a few millimeters and tens of millimeters.

How to program a tube laser 3d cutting ?

3D tube laser cutting machines are usually programmed using CAD/CAM software to convert a 3D model into a program that can be executed by the machine tool.

What auxiliary equipment does the tube laser 3D cutting need?

In addition to the laser and the machine body, auxiliary equipment such as cooling system, compressed air system, and smoke exhaust system are also required.

What are the safety precautions for 3D square tube laser cutting machine thick?

Operators must undergo professional training, wear protective glasses, gloves and other protective equipment, and operate strictly in accordance with operating procedures to avoid direct exposure of the laser beam to the human body.